Polymeric intumescent flame retardant and preparation method thereof

An intumescent flame retardant, polymeric technology, applied in the field of polymeric intumescent flame retardants and preparations, can solve the problems of poor matrix compatibility, poor thermal stability, low molecular weight, etc., and achieve stable reaction, high molecular weight, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

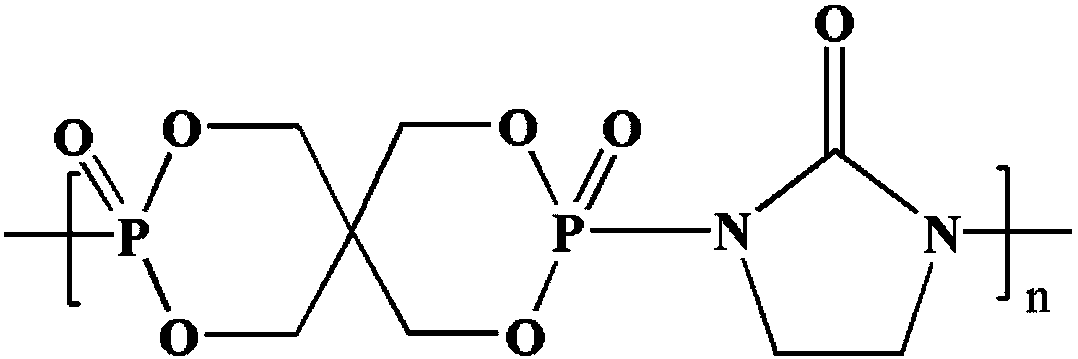

[0024] A polymeric intumescent flame retardant, the structural formula is:

[0025]

[0026] Wherein the degree of polymerization n is an integer between 5-200.

[0027] A kind of preparation method of polymerization type intumescent flame retardant, concrete steps are as follows:

[0028] Weigh 10.2g (0.075mol) of pentaerythritol in a 250mL four-neck flask, add 34.5g (0.225mol) of freshly distilled phosphorus oxychloride and 50mL of anhydrous acetonitrile, connect the thermometer, mechanical stirrer, condenser tube and tail gas absorption device. Under a nitrogen atmosphere, mix at room temperature until the system is stable, then slowly raise the temperature to 80° C., and react until no HCl gas is released (reaction ends). Cool to room temperature, filter the obtained precipitate with suction, wash several times with dichloromethane, acetone or chloroform, and dry in vacuum at 80°C for 12 hours to obtain 20.9 g of a white powdery solid intermediate, which is spirocycli...

Embodiment 2

[0032] A polymeric intumescent flame retardant, the structural formula is:

[0033]

[0034] Wherein the degree of polymerization n is an integer between 5-200.

[0035] A kind of preparation method of polymerization type intumescent flame retardant, concrete steps are as follows:

[0036] Weigh 13.6g (0.1mol) of pentaerythritol in a 250mL four-neck flask, add 53.6g (0.35mol) of freshly distilled phosphorus oxychloride and 70mL of anhydrous acetonitrile, connect the thermometer, mechanical stirrer, condenser tube and tail gas absorption device. Under a nitrogen atmosphere, mix at room temperature until the system is stable, then slowly raise the temperature to 80° C., and react until no HCl gas is released (reaction ends). Cool to room temperature, filter the obtained precipitate with suction, wash several times with dichloromethane, acetone or chloroform, and dry in vacuum at 80°C for 12 hours to obtain 27.9 g of a white powdery solid intermediate, which is spirocyclic p...

Embodiment 3

[0039] A polymeric intumescent flame retardant, the structural formula is:

[0040]

[0041] Wherein the degree of polymerization n is an integer between 5-200.

[0042] A kind of preparation method of polymerization type intumescent flame retardant, concrete steps are as follows:

[0043] Weigh 20.4g (0.15mol) of pentaerythritol in a 500mL four-neck flask, add 91.8g (0.6mol) of freshly distilled phosphorus oxychloride and 90mL of toluene, and connect the thermometer, mechanical stirrer, condenser and tail gas absorption device . Under a nitrogen atmosphere, mix at room temperature until the system is stable, then slowly raise the temperature to 105° C., and react until no HCl gas is released (reaction ends). Cool to room temperature, filter the obtained precipitate with suction, wash several times with dichloromethane, acetone or chloroform, and dry in vacuum at 80°C for 12 hours to obtain 41.9 g of a white powdery solid intermediate, which is spirocyclic phosphate dichl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Combustion level | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com