Comprehensive extraction method for total triterpenoids and polysaccharides in ganoderma lucidum germ bran

A comprehensive extraction and Ganoderma lucidum technology, which is applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, plant/algae/fungus/moss components, etc., can solve the problem of less research on the secondary utilization of Ganoderma lucidum chaff and the destruction of the three-dimensional structure of polysaccharides , polysaccharide extraction rate is not high, to achieve the effect of improving product competitiveness, shortening extraction time, and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Selection: select the ganoderma fungus bag after the mushroom is picked, and choose the ganoderma fungus bag with white mycelium and pollution-free ganoderma;

[0040] 2) Pulverization: remove the outer bag from the ganoderma lucidum bag in step 1, and pulverize the ganoderma lucidum chaff, and pass through a 20-mesh sieve;

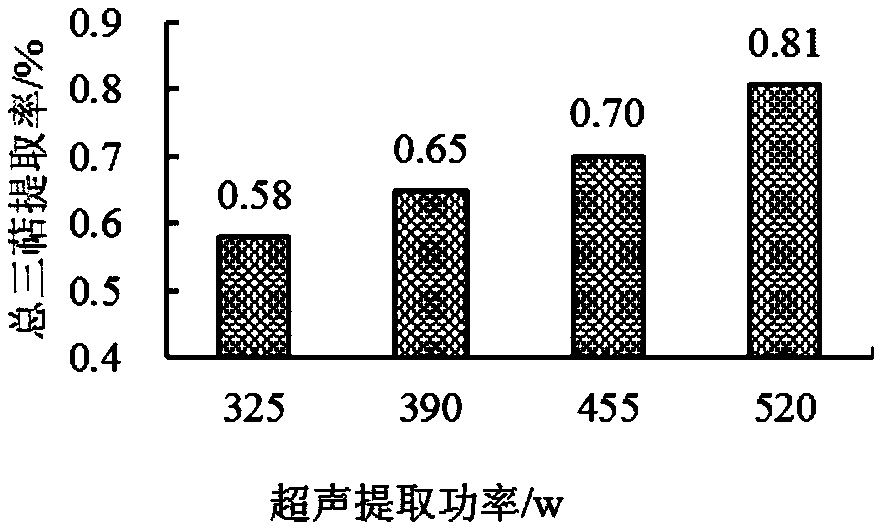

[0041] 3) Ultrasonic extraction: add 75% ethanol with 20 times the weight of the bacterial chaff to the pulverized fungus chaff in step 2), and use an ultrasonic cell breaker to carry out ultrasonic extraction at normal temperature and pressure, the ultrasonic power is 520w, and the extraction time is 5min , the single radiation time is 6s / 5s, and the obtained materials are used for standby.

[0042] 4) Centrifugation: Centrifuge the material in step 3) at a rotating speed of 3000r / min for 5min to obtain filter residue and clear liquid.

[0043] 5) Concentration: Evaporate the clear liquid described in step 4) under reduced pressure, the vacuum...

Embodiment 2

[0054] 1) Selection: select the ganoderma fungus bag after the mushroom is picked, and choose the ganoderma fungus bag with white mycelium and pollution-free ganoderma;

[0055] 2) Pulverization: remove the outer bag from the ganoderma lucidum bag in step 1, and pulverize the ganoderma lucidum chaff, and pass through a 20-mesh sieve;

[0056] 3) Ultrasonic extraction: add 75% ethanol with 15 times the weight of the bacterial chaff to the pulverized fungus chaff described in step 2), and use an ultrasonic cell breaker to carry out ultrasonic extraction at normal temperature and pressure, the ultrasonic power is 585w, and the extraction time 3min, single irradiation time 6s / 5s, the obtained materials are used for later use.

[0057] 4) Centrifugation: Centrifuge the material in step 3) at a rotating speed of 3000r / min for 5min to obtain filter residue and clear liquid.

[0058] 5) Concentration: Evaporate the clear liquid described in step 4) under reduced pressure, the vacuum ...

Embodiment 3

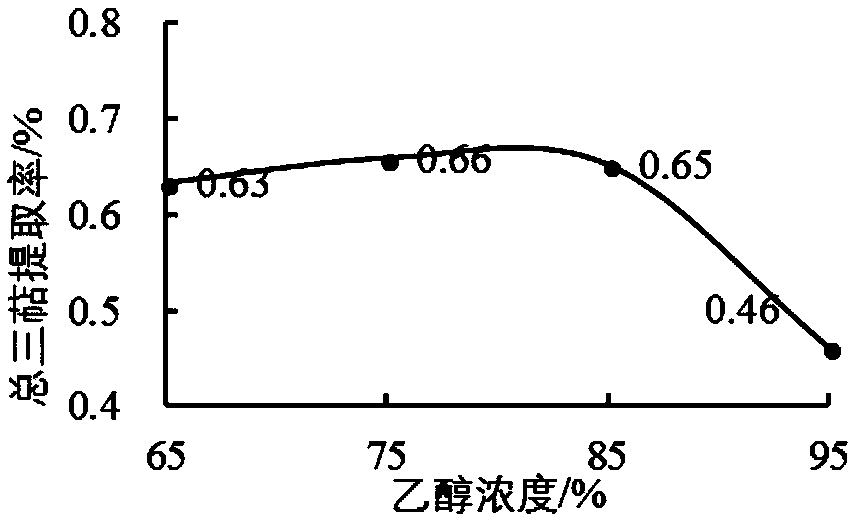

[0069] 1. Effect of ethanol concentration on the extraction rate of total triterpenes from Ganoderma lucidum residue

[0070] Accurately weigh 5.00 g of Ganoderma lucidum residue, 3 parts in total, add 50 mL of ethanol solution respectively, the ethanol concentration is 65%, 75%, 85% and 95% respectively. The extraction power is 60%, the single irradiation time is 6.0s / 5.0s, and ultrasonic extraction is performed at room temperature for 20 minutes. Then cool to room temperature, shake well, filter with filter paper to obtain the extract, take the filtrate, and dilute to 100mL, the solution is to be tested.

[0071] Depend on figure 1 It can be seen that in the range of 65% to 95% ethanol concentration, the extraction rate of total triterpenoids from Ganoderma lucidum residues gradually increases to the highest point and then slowly decreases, and the extraction rate of total triterpenes from Ganoderma lucidum residues reaches the highest when the ethanol concentration is 75% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com