A salt mine mining method using horizontal branch holes butt joint well group

A technology of horizontal branching and mining method, applied in surface mining, fluid mining, underground mining, etc., can solve the problems of ineffective mining, easy closure and blockage, low total salt mining, etc., so as to reduce the damage of vegetation. , The effect of reducing development cost and extending service period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

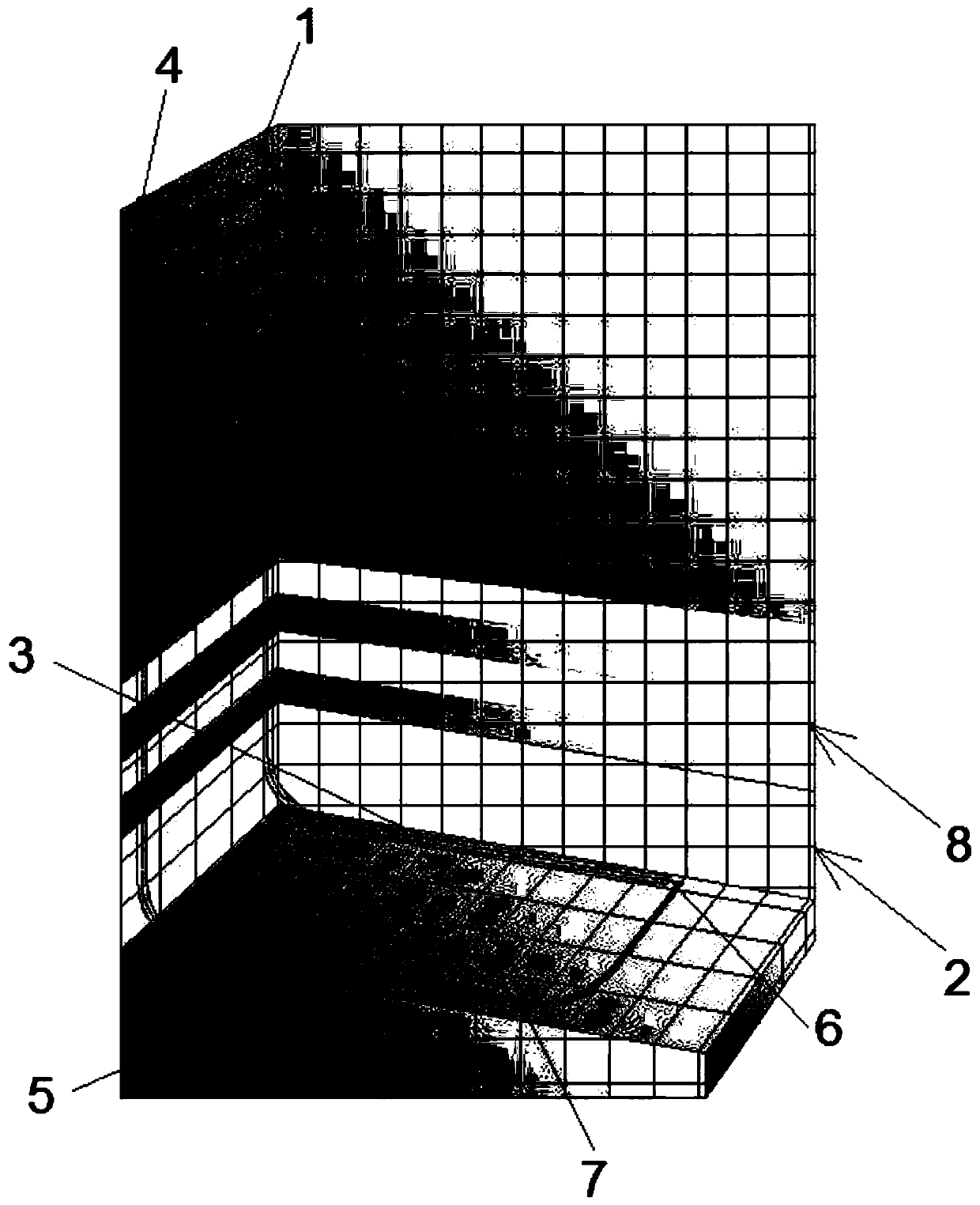

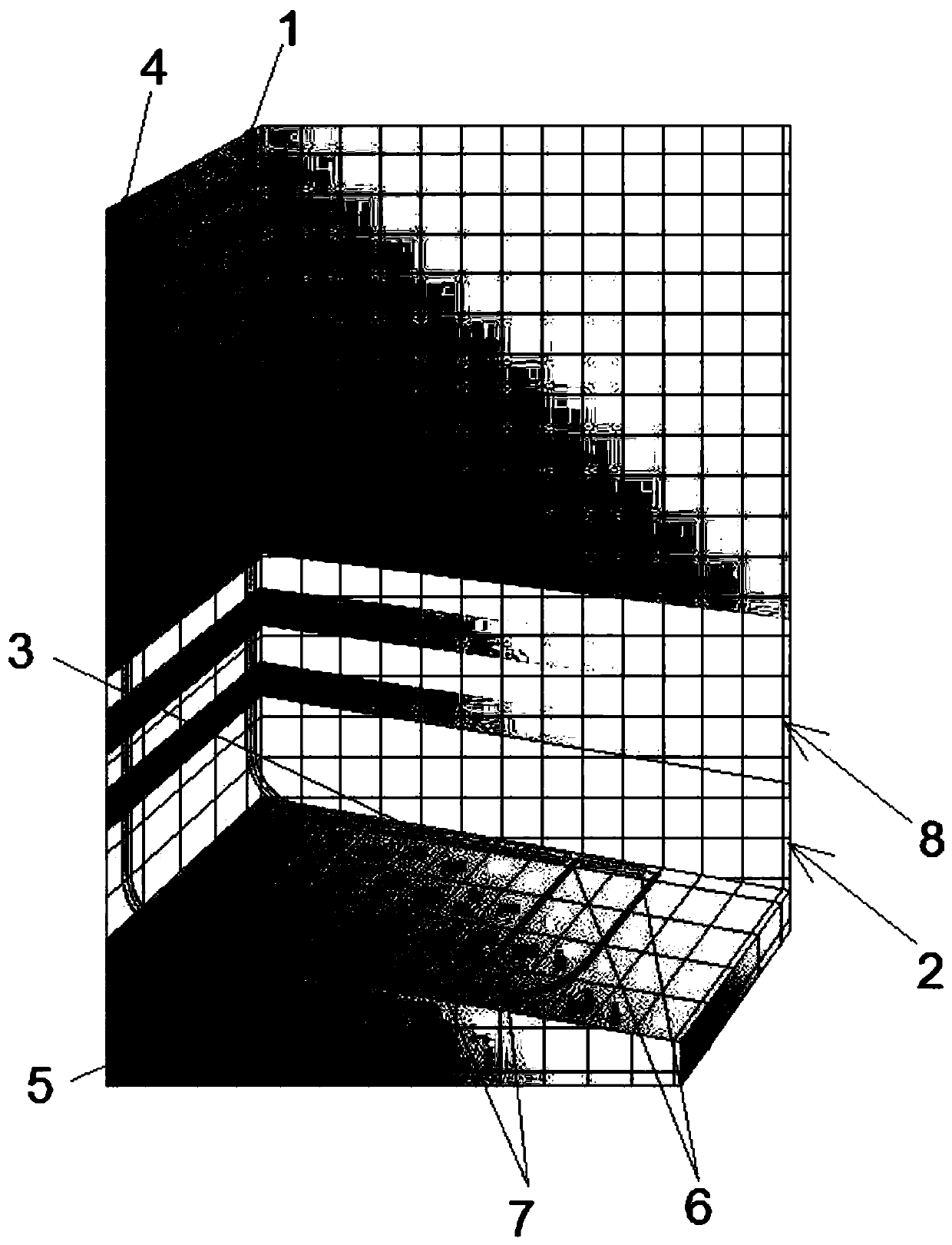

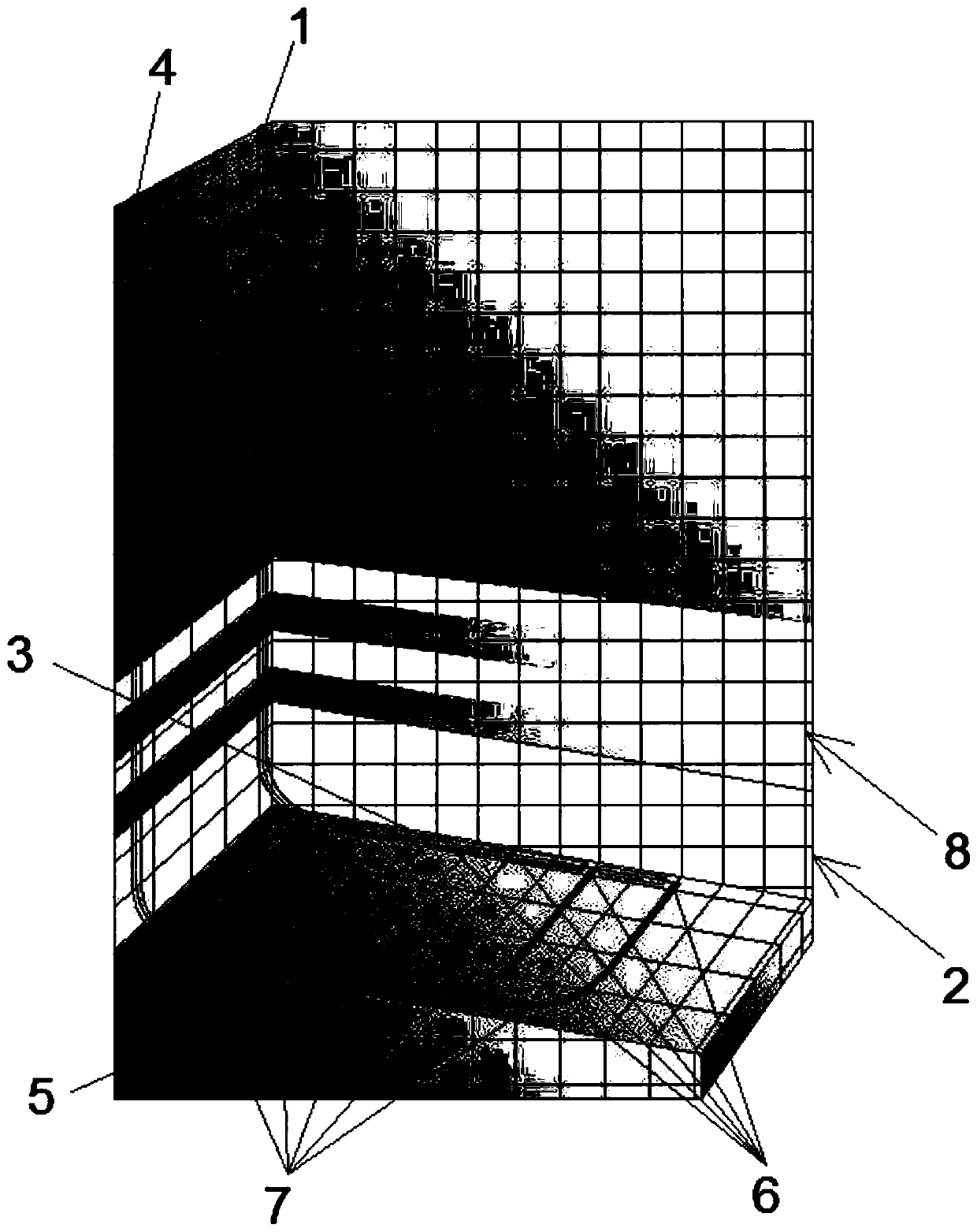

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0039] Such as Figure 1-Figure 4 As shown, the present invention discloses a salt mine mining method using horizontal branch holes butt joint well groups, comprising the following steps:

[0040] 1) Drill a first vertical well section 1 on the ground to the lower salt layer 2 of the salt mine, and drill a first lower horizontal well section 3 to a preset horizontal branch hole along the lower salt layer 2 after building up Target point 6, the first brine well is formed by the first vertical well section 1 and the first lower horizontal well section 3, wherein the deflection drilling is used between the first vertical well section 1 and the first lower horizontal well section 3 connection, and the radius of curvature of the ramp is 300m.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com