Method for treating residual atrazine in water body by LaFe(1-x)CuxO3

A technology of atrazine and water body, applied in the direction of water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problem of low catalytic efficiency, achieve high catalytic efficiency, short reaction time, reduce acid The effect of base adjustment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

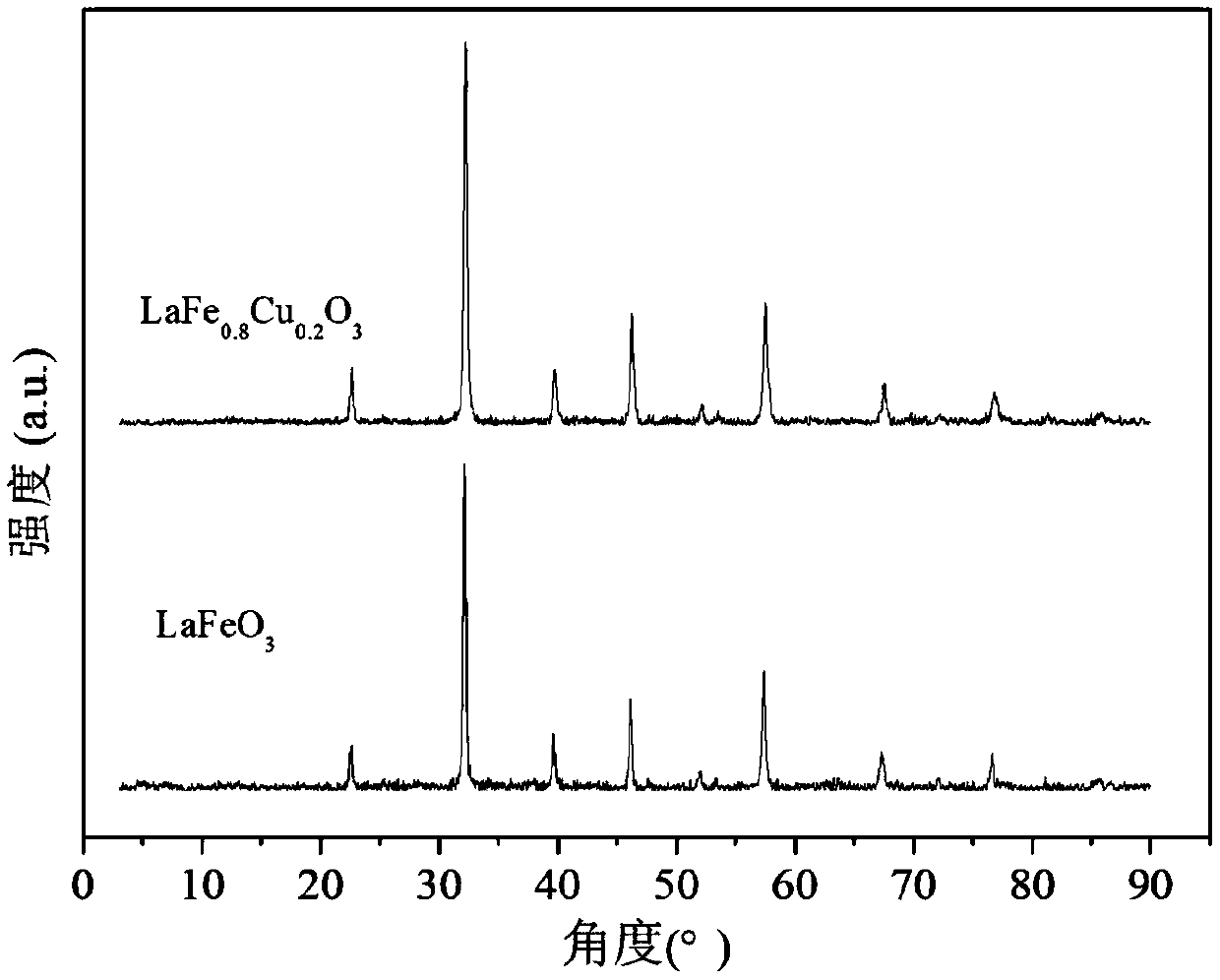

[0052] Example 1: compared the use of LaFe 1-x Cu x o 3 Material activated persulfate, adding LaFe alone 1-x Cu x o 3 materials and the removal rate of atrazine in three ways of adding peroxymonosulfate alone.

[0053] (1) Using LaFe with different doping ratios 1-x Cu x o 3 (LaFeO 3 、LaFe 0.9 Cu 0.1 o 3 、LaFe 0.8 Cu 0.2 o 3 、LaFe 0.7 Cu 0.3 o 3 、LaFe 0.6 Cu 0.4 o 3 、LaFe 0.5 Cu 0.5 o 3 ) In the heterogeneous reaction of material activated potassium hydrogen persulfate, the Erlenmeyer flask is used as the reactor, the waste water reaction volume is 200mL, the treatment condition is that the initial concentration of the waste water containing atrazine is 5.0 mg / L, and the reaction Add LaFe to the bottle 1-x Cu x o 3 The concentrations of the materials and potassium monopersulfate are respectively 0.5 g / L and 0.5 mmol / L, and the reaction bottle is placed in a shaker with a rotation speed of 180 rpm and a temperature of room temperature.

[0054] (2) Ad...

Embodiment 2

[0058] Embodiment 2: compare different LaFe 0.8 Cu 0.2 o 3 Effect of material dosage on the removal rate of atrazine

[0059] (1) Using LaFe 0.8 Cu 0.2 o 3 In the heterogeneous reaction of material catalyst to activate potassium monopersulfate, the Erlenmeyer flask is used as the reactor, the reaction volume of wastewater is 200mL, the treatment conditions are that the initial concentration of atrazine-containing wastewater is 5.0mg / L, and the reaction starts to proceed to the reaction Potassium peroxomonosulfate was added in the bottle to make the concentration 0.5mmol / L, and LaFe was added to the reaction bottle at the same time. 0.8 Cu 0.2 o 3 The material is used to make the reaction concentration 0.25g / L, and finally the reaction bottle is placed in a vibrating bed with a rotation speed of 180rpm, a temperature of room temperature, and a time of 90min.

[0060] (2) In the reaction wastewater LaFe 0.8 Cu 0.2 o 3 The material is 0.75g / L, just adding LaFe 0.8 Cu ...

Embodiment 3

[0062] Example 3: Effects of Different Dosages of Potassium Monopersulfate on Activation and Degradation of Atrazine

[0063] (1) Using LaFe 0.8 Cu 0.2 o 3 In the heterogeneous reaction of catalytically activating potassium monomonosulfate, an Erlenmeyer flask is used as a reactor to process 200 mL of organic wastewater whose initial concentration of atrazine is 5.0 mg / L, and potassium monomonosulfate is added in the reaction flask, Add LaFe to the reaction flask at the same time 0.8 Cu 0.2 o 3 , so that potassium peroxosulfate and LaFe 0.8 Cu 0.2 o 3 The concentrations in the organic wastewater solution were 0.25mmol / L and 0.5g / L respectively, and finally the reaction bottle was placed in a shaker with a rotation speed of 180rpm, a temperature of room temperature, and a time of 90min.

[0064] (2) Only when adding potassium monopersulfate, adjust the dosage of potassium monopersulfate so that the final concentration in the organic wastewater solution is 0.75mmol / L, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com