Preparation method of double-pyridine type ironic liquid

A technology of ionic liquid and bipyridine, which is applied in the field of preparation of bipyridine ionic liquid, can solve the problems of restricting the large-scale production of ionic liquid, difficult to remove impurity ions, long reaction time, etc., achieve good application prospects and high product yield , the effect of compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

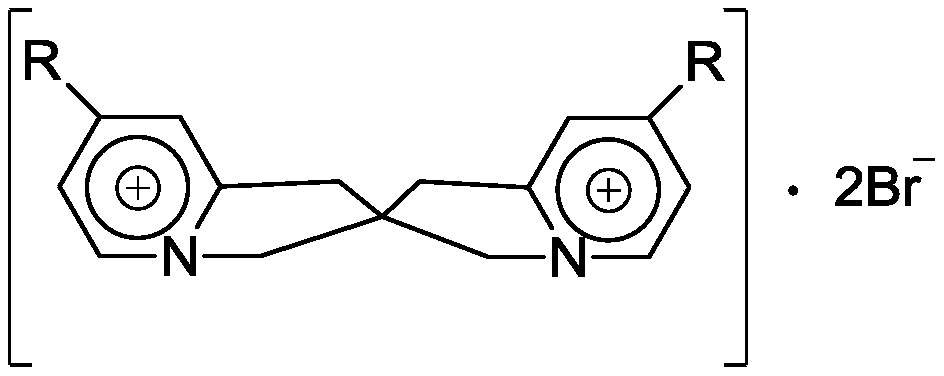

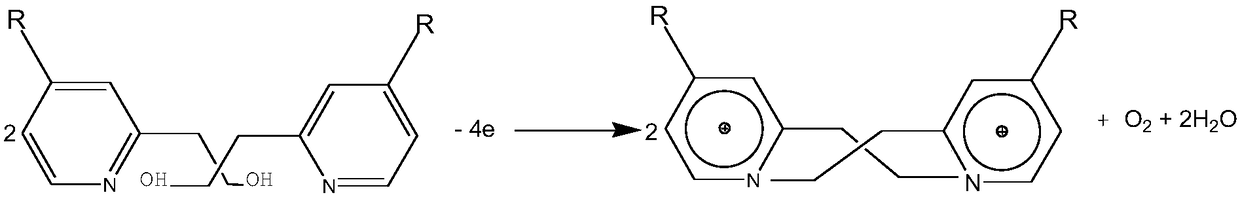

[0031] A kind of preparation method of bipyridine ionic liquid, is provided with at least one layer of cation exchange membrane in electrolyzer, described cation exchange membrane divides electrolyzer into cathode room and anode room, adopts PbO 2 As the anode, graphite as the cathode, the concentration of 2.5mol / L 2,2-bis-(4-alkylpyridine)methyl-1,3-propanediol aqueous solution is added in the anode chamber of the electrolytic cell as the anolyte, and the content Acetonitrile mixed aqueous solution that is 10wt% KBr is added in the cathode compartment of the electrolytic cell as the catholyte, the power is turned on, the electrolysis temperature is 50°C, and the current density is 0.75A / dm 2 Under the conditions of constant current electrolysis for 2h, the catholyte was taken out after the electrolysis was completed, separated and purified to obtain the bis[pyrrolo(1,2-A)-4-picoline] dibromide of the bispyridine ionic liquid, the purity 90wt%.

Embodiment 2

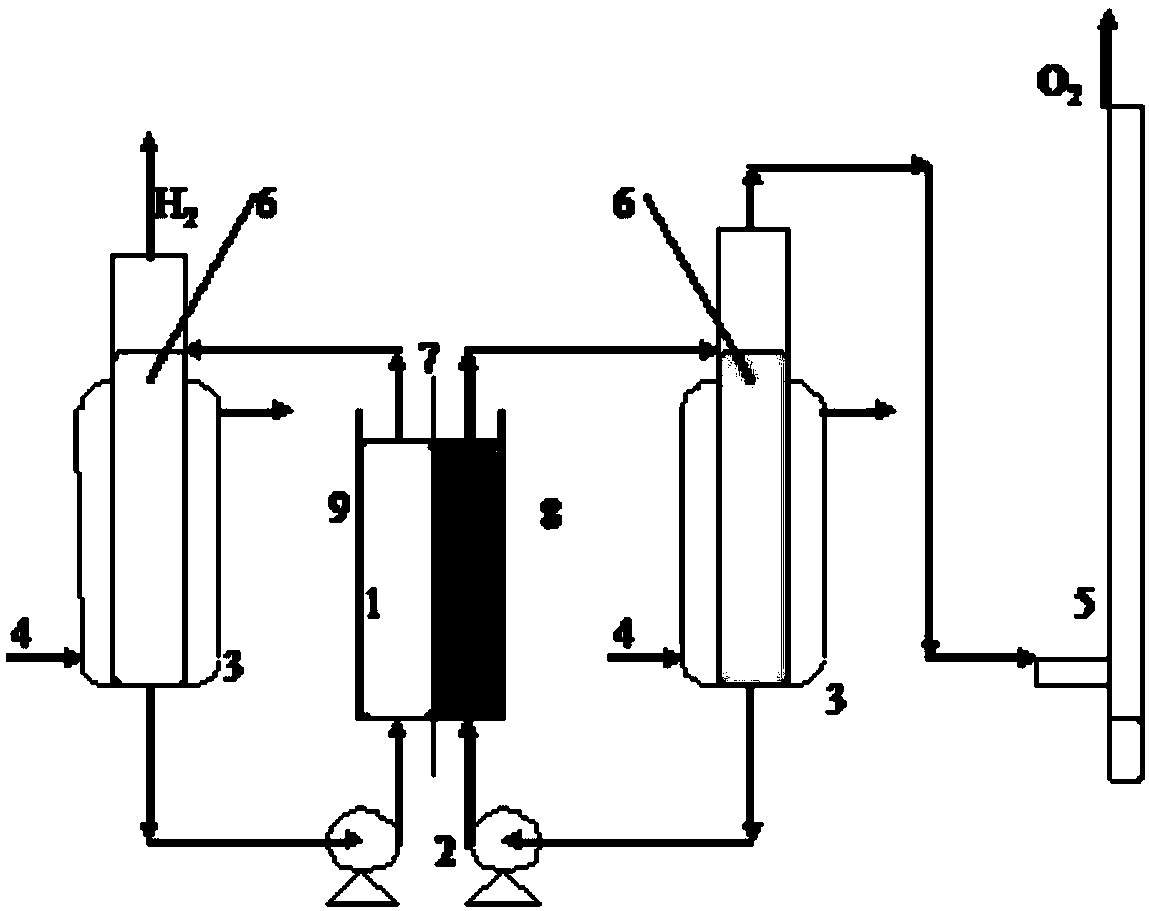

[0033] A kind of preparation method of bispyridine ionic liquid, in two storage tanks respectively filled with 3.5mol / L 2,2-bis-(4-alkylpyridine)methyl-1,3-propanediol aqueous solution as anode Electrolyte, the mixed aqueous solution of acetonitrile of 10wt% KBr is the catholyte, the said anolyte of 1500mL and the said catholyte of 1500mL are respectively added in two storage tanks, and respectively by two circulating pump Connected with one liquid storage tank, the cathode chamber of the electrolyzer communicates with another liquid storage tank. Turn on the circulation pump, and turn on the DC power supply at the same time, and use the Nafion 902 cation exchange membrane as the diaphragm to divide the electrolytic cell into a cathode chamber and an anode chamber, PbO 2 The anode is used as the anode, and the graphite is used as the cathode. The cathode and anode liquids pass through the cathode chamber and the anode chamber respectively at a flow rate of 300L / h to form a clo...

Embodiment 3

[0035] A kind of preparation method of bipyridine ionic liquid, in two liquid storage tanks respectively filled with 2,2-bis-(4-alkylpyridine)methyl-1,3-propanediol aqueous solution as anode electrolysis Liquid, the acetonitrile mixed aqueous solution of 13wt% KBr is the catholyte, the anolyte and the catholyte are respectively added in two liquid storage tanks, and the anode chamber of the electrolytic cell is connected to a storage tank by two circulation pumps respectively. The liquid tank, the cathode chamber of the electrolytic cell communicates with another liquid storage tank. Turn on the circulation pump, and turn on the DC power supply at the same time, and use the Nafion 902 cation exchange membrane as the diaphragm to divide the electrolytic cell into a cathode chamber and an anode chamber, PbO 2 The anode is used as the anode, and the graphite is used as the cathode. Both the cathode and anode electrolytes pass through the cathode chamber and the anode chamber resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com