Kaoliang spirit raw material processing equipment

A processing equipment and technology of sorghum wine, which is applied in the direction of solid separation, separation of solids from solids by air flow, wet separation, etc., which can solve the problems of dust adhesion and incomplete cleaning, and achieve the effect of cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

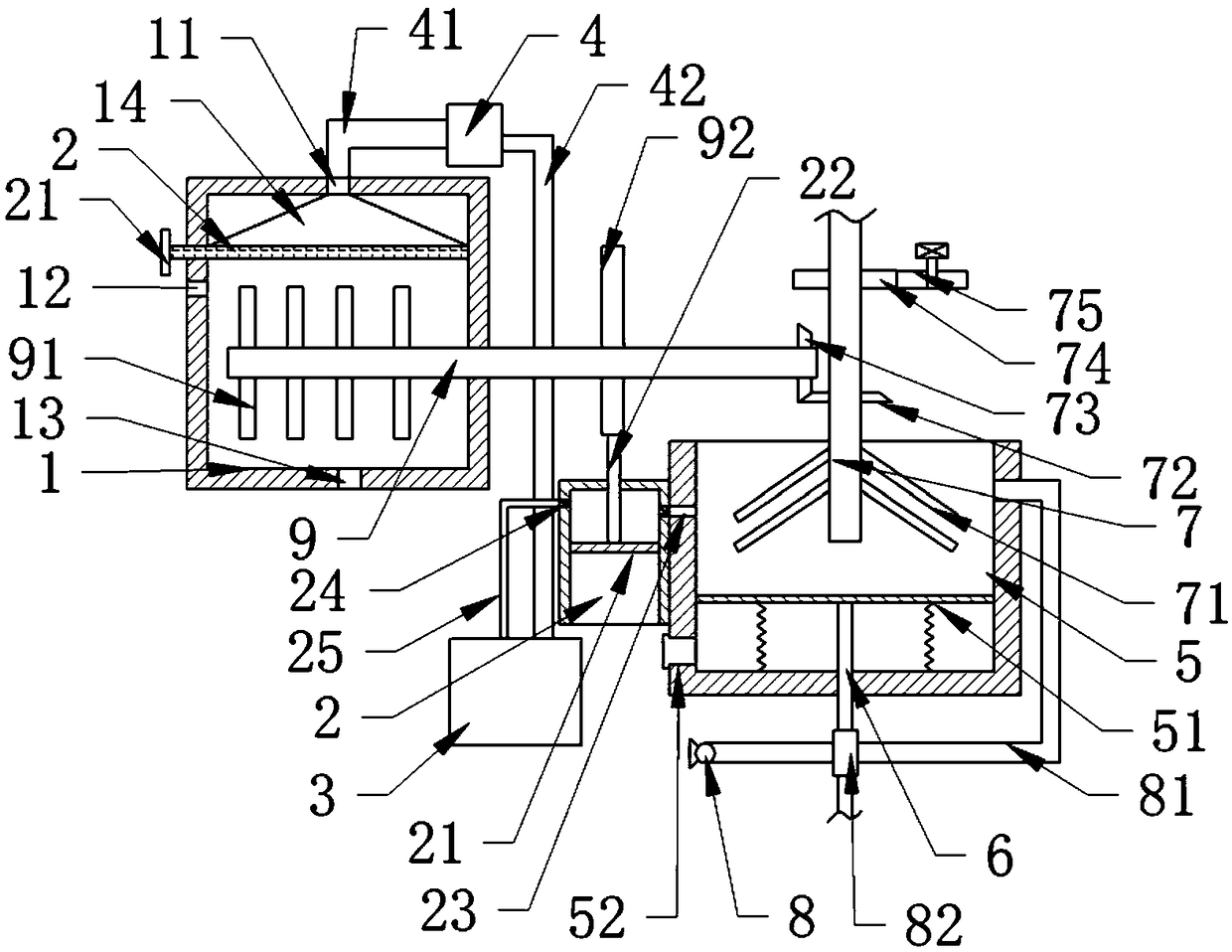

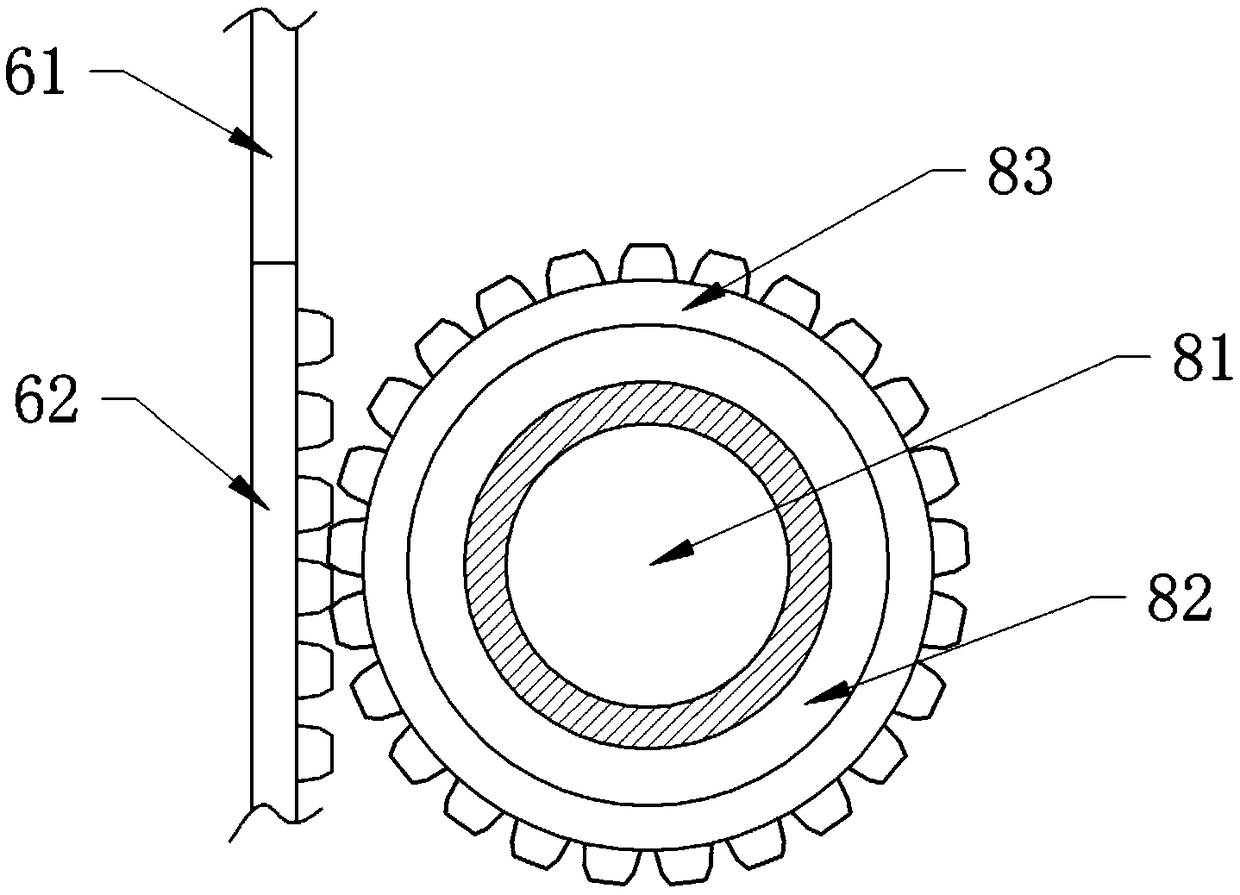

[0028] The reference signs in the drawings of the description include: screening box 1, screening port 11, feed port 12, material guide port 13, guide cover 14, screen 2, limit block 21, liquid guide barrel 2, slide plate 21, moving Rod 22, liquid inlet pipe 23, liquid outlet 24, liquid outlet pipe 25, collection box 3, exhaust fan 4, screening pipe 41, air outlet pipe 42, cleaning bucket 5, support plate 51, material outlet 52, push rod 6. Sliding part 61, rack part 62, rotating shaft 7, stirring blade 71, driving bevel gear 72, driven bevel gear 73, driven gear 74, driving gear 75, water pump 8, conduit 81, rotary valve 82, ring gear 83, rotating shaft 9, stirring blade 91, cam 92.

[0029] The embodiment is basically as attached figure 1 Shown:

[0030] The sorghum wine raw material processing equipment includes a frame on which a screening box 1, a liquid guiding b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com