Long-acting slow-release facial mask and preparation method thereof

A slow-release mask and long-acting technology, applied to medical preparations containing active ingredients, manufacturing tools, welding equipment, etc., can solve problems such as complex sources of raw materials, and achieve the effects of improving adsorption effect, avoiding pollution, and using safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

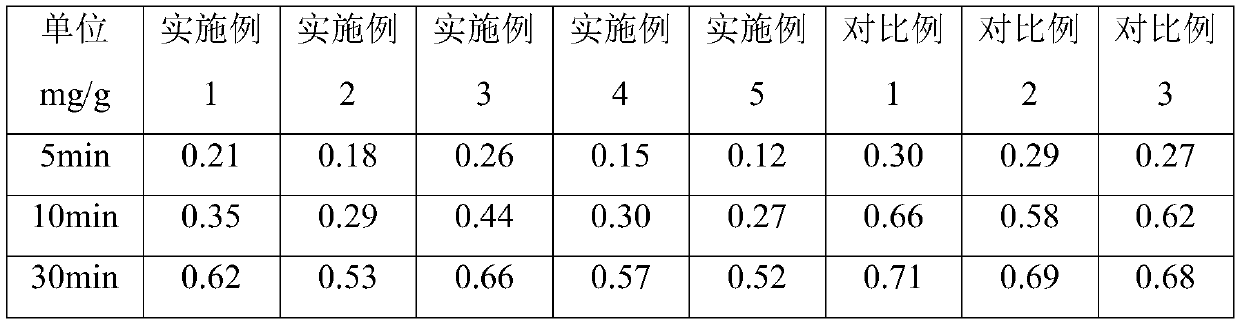

Examples

Embodiment 1

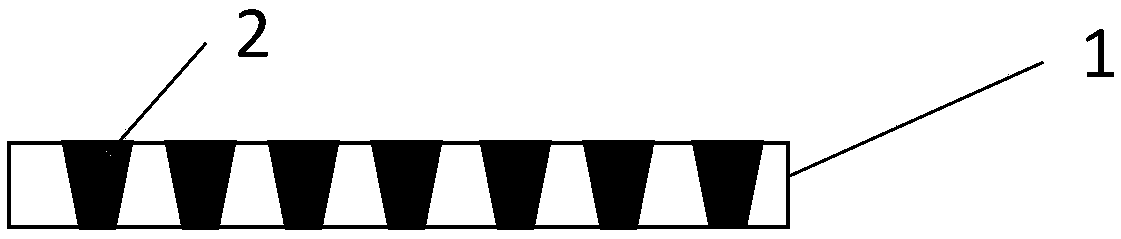

[0033] S1. Polyester is used as raw material: the base fabric is obtained after opening, carding, spunlace reinforcement, and drying, with a thickness of 180 μm and an area of 15*15 cm.

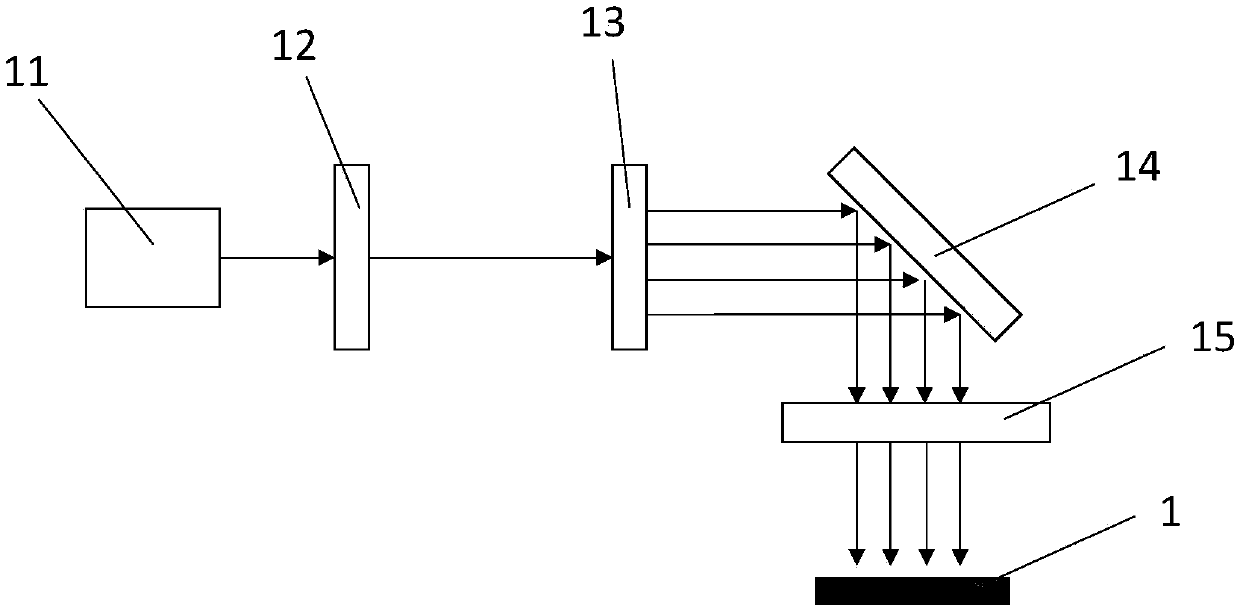

[0034] S2. The laser source adopts CO2 laser, the pulse frequency is 30kHz, the power is 100W, the action time of single hole is 0.1ms, and the scanning rate is 50mm / s. The hole spacing is 100μm;

[0035] S3. prepare the block copolymer of polyethylene oxide and polyethylene terephthalate, deionized water as the solution containing hydrophilic agent, control the content of hydrophilic agent to be 30wt%, and heat the solution after mixing evenly to 60°C, then dip the porous base cloth into a solution containing a hydrophilic agent for 35 minutes to obtain a hydrophilic porous base cloth;

[0036]S4. Prepare a functional component solution containing 20 mg / mL of keratin, and soak the hydrophilic porous base cloth in the solution containing the functional component for 60 minutes to obtain a ...

Embodiment 2

[0038] The conditions are the same as in Example 1, wherein, after the microholes are processed by laser in step S2, the process of purging the formed microholes with a cooling medium (nitrogen at 20°C) is also included immediately, and the single hole purging time is 0.2s.

Embodiment 3

[0040] S1. Polyester is used as raw material: the base fabric is obtained after opening, carding, spunlace reinforcement, and drying, with a thickness of 180 μm and an area of 15*15 cm.

[0041] S2. The laser source adopts CO2 laser, the pulse frequency is 30kHz, the power is 100W, and the action time of a single hole is 0.1ms. The hole diameter is 80μm and the hole depth is 180μm (punched through the base fabric to form a through hole); the hole spacing is 1mm;

[0042] S3. prepare the block copolymer of polyethylene oxide and polyethylene terephthalate, deionized water as the solution containing hydrophilic agent, control the content of hydrophilic agent to be 30wt%, and heat the solution after mixing evenly to 60°C, then dip the porous base cloth into a solution containing a hydrophilic agent for 35 minutes to obtain a hydrophilic porous base cloth;

[0043] S4. Prepare a functional component solution containing 20 mg / mL of keratin, and soak the hydrophilic porous base cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com