A kind of fabricating method of broadband tunable terahertz wave absorber

A production method and terahertz technology, applied in the terahertz field, can solve problems such as limited bandwidth and large volume, and achieve the effect of realizing tunable characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

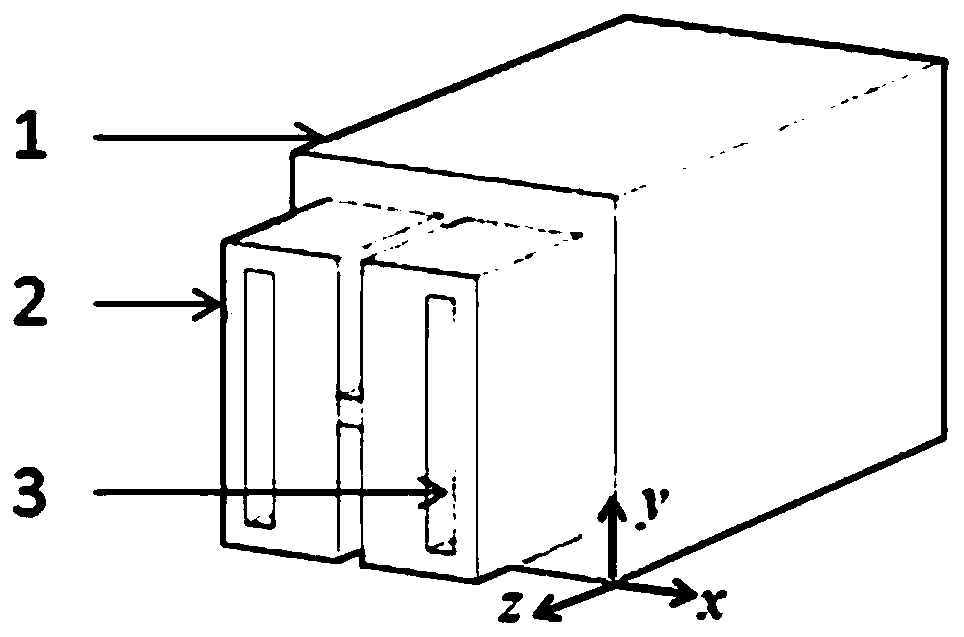

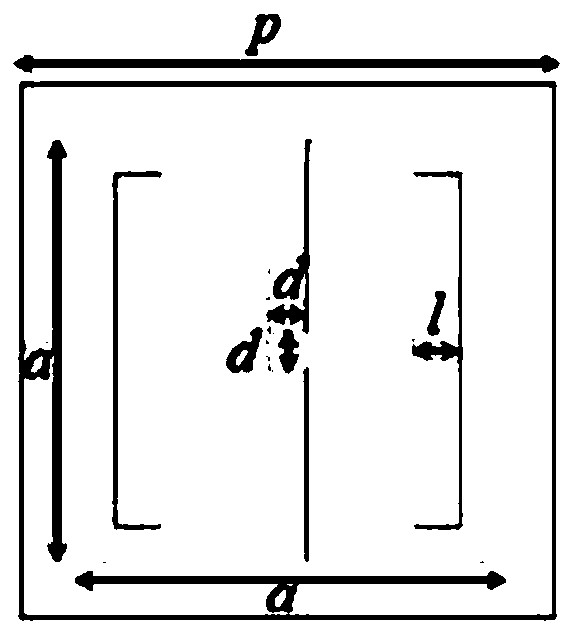

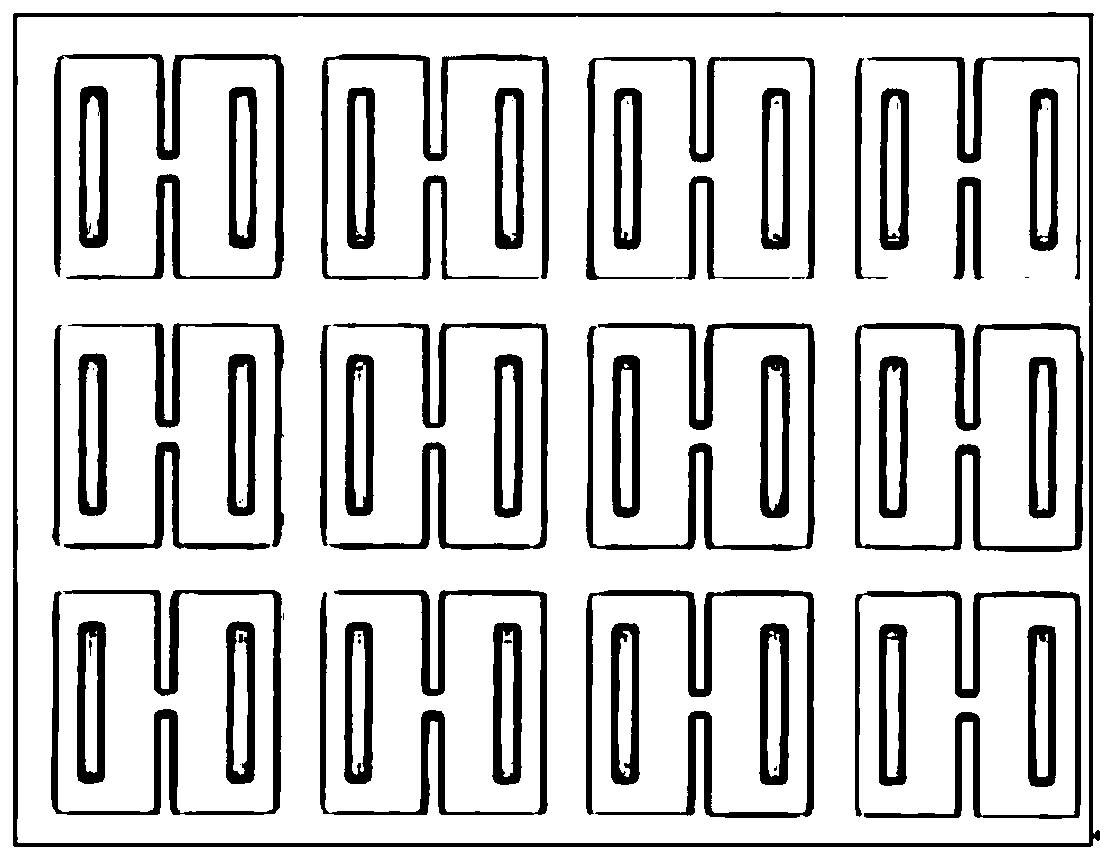

[0031] A broadband tunable terahertz wave absorber of the present invention, the structure of which is shown in Figure 1(a), Figure 1(b) and figure 2 As shown, a doped semiconductor material matrix 1 is included, and a layer of microstructure array is formed on the surface of the doped semiconductor material matrix 1. The microstructure array includes a number of uniformly arranged microstructure units 2, and the microstructure unit 2 can respond to THz waves. A rectangular waveguide structure 3 is also designed in the structural unit 2 to increase the absorption bandwidth.

[0032] The doped semiconductor material substrate 1 is a p-type silicon material, and the doping concentration is ~0.3×10 17 / cm 3 , the thickness of the semiconductor material matrix is 250-300 μ mm, and the resistivity is 0.5 Ω·cm.

[0033] The microstructure unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com