A kind of porous multi-layer composite diaphragm and preparation method thereof

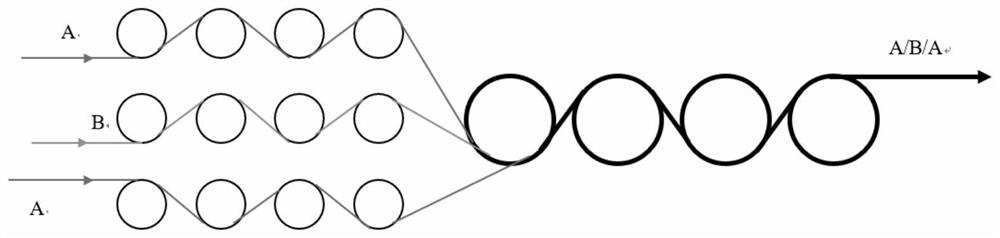

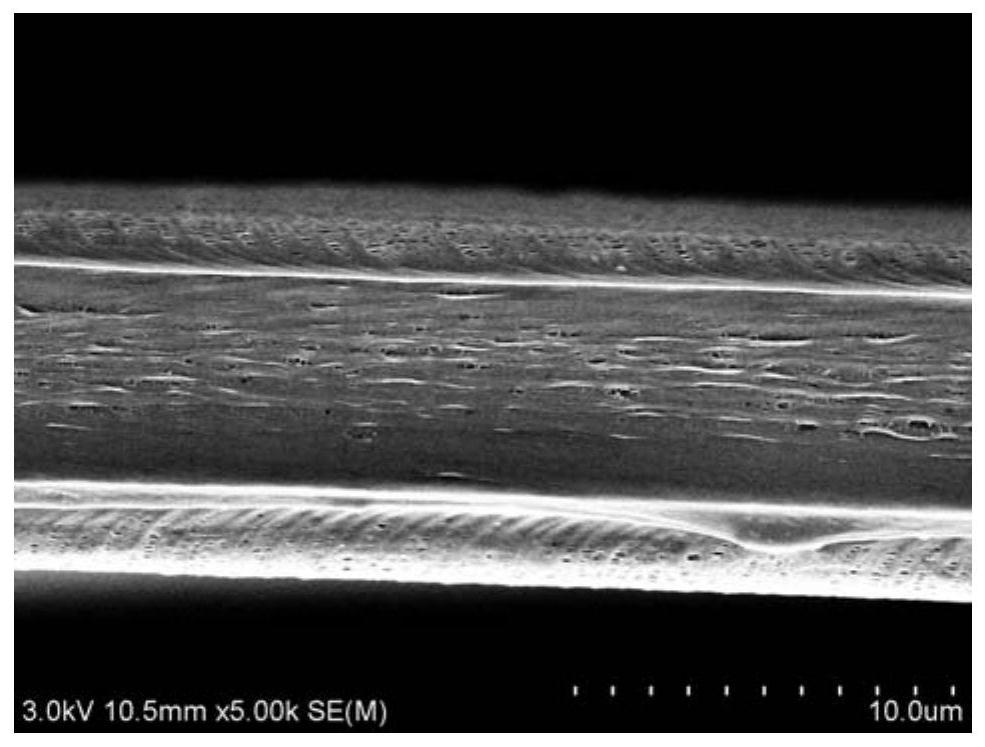

A multi-layer composite and diaphragm technology is applied in the field of porous multi-layer composite diaphragm and its preparation, polypropylene/polyethylene/polypropylene porous multi-layer composite diaphragm and its preparation field, which can solve the rising cost and the inability to have large differences in material properties. problems such as poor uniformity of thin films and micropores, to achieve the effects of good uniformity and consistency, good ionic conductivity, and high interface consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Material preparation: the density is 0.91-0.93g / cm 3 , Polypropylene (PP) with a molecular weight of 300,000 is used as the surface layer polypropylene raw material. The density is 0.94-0.96g / cm 3 , High-density polyethylene (PE) with a molecular weight of 400,000 is used as the high-density polyethylene raw material for the core layer.

[0051] (2) Preparation of PP cast film: use a single-screw extruder with an aspect ratio L / D≥34 to melt and extrude polypropylene raw materials, and the extrusion temperature is between 160-230°C. After the melt is filtered and metered, it enters the flat die head, flows out from the die lip to form a sheet, and adheres to the casting roller to form a hard elastic casting film with a film thickness of 8-30 microns. Wherein the die draft ratio DDR is 80-180, and the casting roll temperature is 70-120°C.

[0052] (3) Preparation of PE casting film: use a twin-screw extruder with an aspect ratio L / D≥32 to melt and extrude high-dens...

Embodiment 2

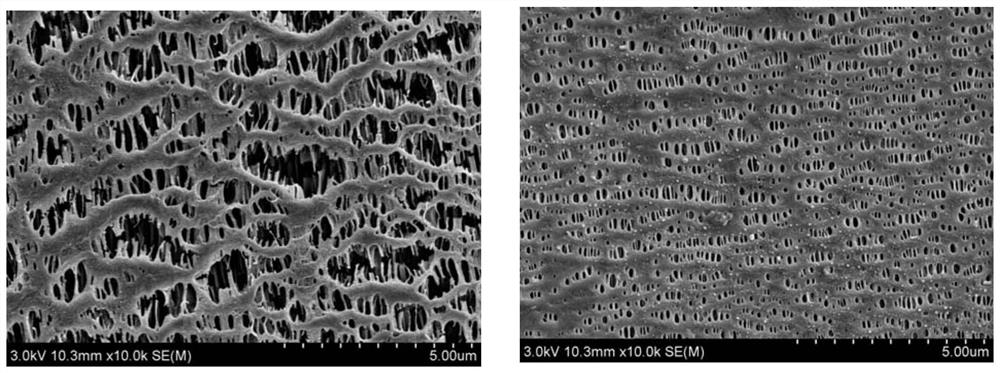

[0059] This example uses the same materials and process steps as in Example 1, but in step (5), the stretching speed ratio of the PP layer is 2.1-2.3, and the stretching speed ratio of the PE layer is 1.8-2.0, and PP / PE / PP is obtained Porous multilayer composite separator.

[0060] The obtained porous multi-layer composite diaphragm has been determined to have an average porosity of 37%, wherein the porosity of the PP layer is 40%, the porosity of the PE layer is 35%; the air permeability is 322s / 100ml; It is 0.32% / week, and the capacity retention rate is 93% after 1C cycle for 2000 cycles.

Embodiment 3

[0062] This example uses the same materials and process steps as Example 1, but in step (5), the stretching speed ratio of the PP layer is 2.8-3, and the stretching speed ratio of the PE layer is 1.6-1.8, and PP / PE / PP is obtained Porous multilayer composite separator.

[0063] The obtained porous multi-layer composite diaphragm is measured, with an average porosity of 37%, wherein the porosity of the PP layer is 49%, the porosity of the PE layer is 30%; the air permeability is 291s / 100ml; It is 0.21% / week, and the capacity retention rate is 91% after 1C cycle for 2000 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com