Production process for producing high-grade coated white manila board by using ONP (Old News Paper) pulp instead of DIP (Deinked Pulp) pulp

A production process and coating technology, which is applied in the direction of natural cellulose pulp/paper, paper, papermaking, etc., can solve the problems of low yield of advanced coated gray bottom white board paper pulp, high production cost, etc., and meet the cleanliness requirements Low, reduce the amount of use, improve the effect of pulp yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

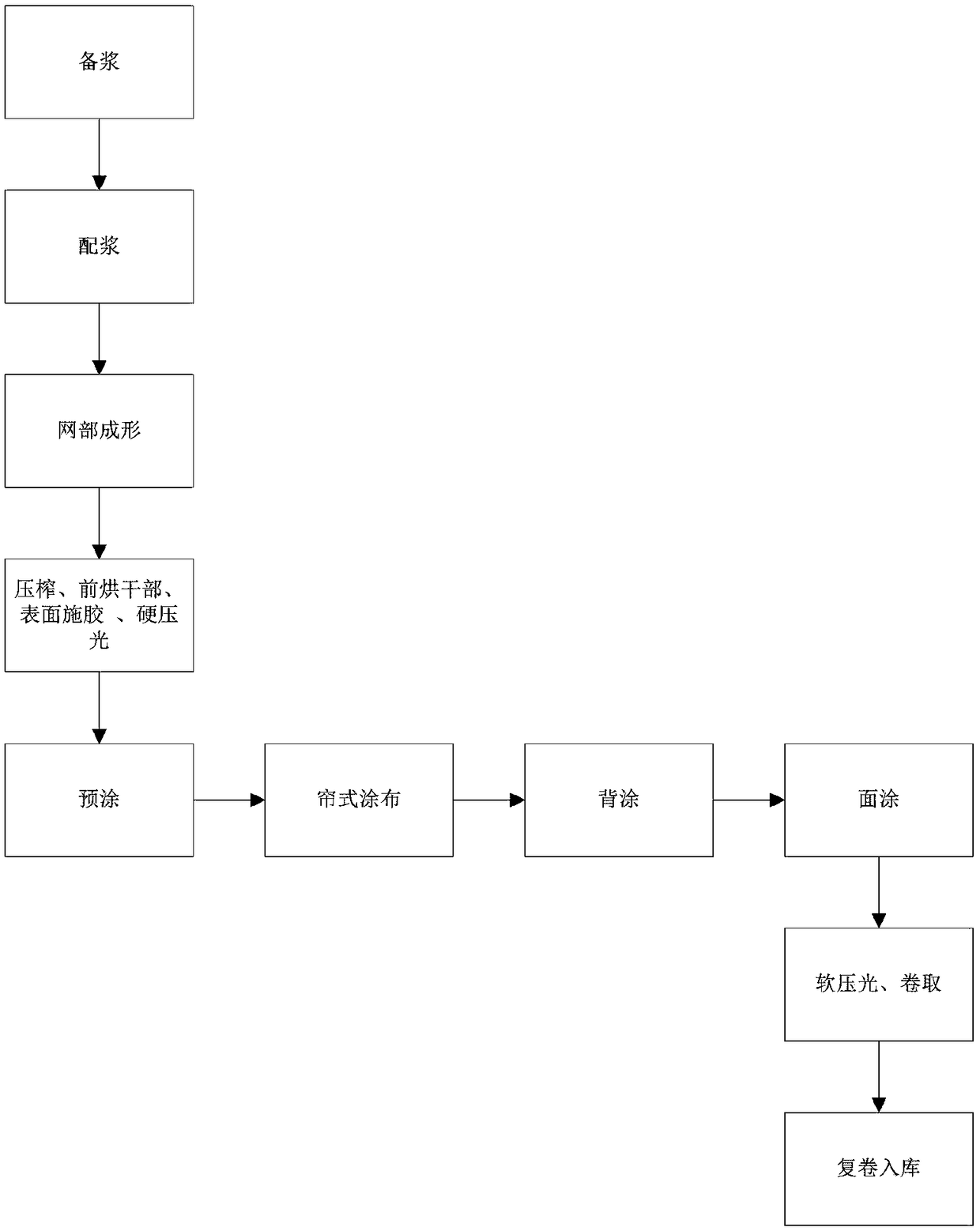

[0038] see figure 1 , this embodiment provides a production process for ONP pulp instead of DIP pulp to produce advanced coated gray-bottomed white board paper, including the following steps:

[0039] Stock preparation:

[0040] Surface layer ONP pulp preparation: use ONP instead of DIP as raw material, prepare surface layer ONP pulp through waste paper deinking pulping line, the ONP deinked pulp has a freeness of 200csf, a whiteness value of 40ISO, and a content of impurity points of 800mm 2 / m 2 ;

[0041] Liner OCC stock preparation: use waste containerboard pulp as raw material, process it through OCC pulp line, and classify and screen out OCC medium fiber pulp, after being treated by heat removal and dispersion system, the stickies and oily wax in the pulp are effectively dispersed , the OCC medium fiber becomes liner OCC pulp after disc refining and refining, and the freeness of the liner OCC pulp is 230ml;

[0042] Using wood chips as raw materials, wood pulp is pro...

Embodiment 2

[0060] see figure 1 , this embodiment provides a production process for ONP pulp instead of DIP pulp to produce advanced coated gray-bottomed white board paper, including the following steps:

[0061] Stock preparation:

[0062] Surface layer ONP pulp preparation: use ONP instead of DIP as raw material, prepare surface layer ONP pulp through waste paper deinking pulping line, the ONP deinked pulp has a freeness of 220csf, a whiteness value of 45ISO, and a content of impurity points of 1000mm 2 / m 2 ;

[0063] Liner OCC stock preparation: use waste containerboard pulp as raw material, process it through OCC pulp line, and classify and screen out OCC medium fiber pulp, after being treated by heat removal and dispersion system, the stickies and oily wax in the pulp are effectively dispersed , the OCC medium fiber forms liner OCC pulp after disc refining and pulping, and the freeness of the liner OCC pulp is 248ml;

[0064] Using wood chips as raw materials, wood pulp is produ...

Embodiment 3

[0081] see figure 1 , the present embodiment provides a production method of ONP pulp instead of DIP pulp to produce high-grade coated gray-bottomed whiteboard, comprising the following steps:

[0082] Stock preparation:

[0083] Surface layer ONP pulp preparation: use ONP instead of DIP as raw material, prepare surface layer ONP pulp through waste paper deinking pulping line, the ONP deinked pulp has a freeness of 210csf, a whiteness value of 42ISO, and a content of impurity points of 900mm 2 / m 2 ;

[0084] Liner OCC stock preparation: waste containerboard pulp is used as raw material, processed through the OCC pulp production line, and the graded and screened OCC medium-fiber pulp is processed by the heat removal and dispersion system, and the stickies and oily wax in the stock are effectively dispersed , the OCC medium fiber becomes liner OCC pulp after disc refining and pulping, and the freeness of the liner OCC pulp is 249ml;

[0085] Using wood chips as raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com