High-temperature resistant and wear-resistant coating material for military electronic components and preparation method thereof

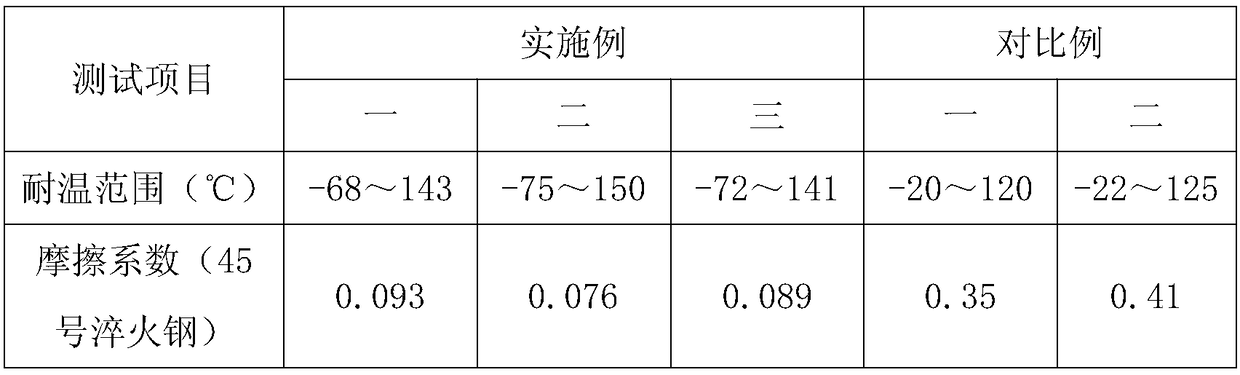

A technology of electronic components and wear-resistant coatings, applied in coatings, fire-resistant coatings, epoxy resin coatings, etc., can solve the problems of large friction coefficient, short service life, narrow temperature resistance range, etc. The effect of long service life and wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A high-temperature-resistant and wear-resistant coating material for military electronic components proposed by the present invention comprises the following raw materials in parts by weight:

[0018] 30 parts of epoxy resin, 30 parts of polyurethane resin, 1 part of polytetrafluoroethylene micro-powder wax, 1 part of ammonium sulfate, 3 parts of isobutyltriethoxysilane, 5 parts of talcum powder, 2 parts of nano silicon dioxide, antioxidant 1 part of agent, 1 part of dispersant.

[0019] Its preparation method comprises the following steps:

[0020] S1. According to the specific gravity, add polytetrafluoroethylene micropowder wax and ammonium sulfate into isobutyltriethoxysilane, stir at a speed of 300r / min for 5min, then add talc powder and nano silicon dioxide, and ultrasonically Evenly dispersed mixture A;

[0021] S2. According to the specific gravity, epoxy resin, polyurethane resin, antioxidant, dispersant and the mixture A obtained in step S1 are jointly added...

Embodiment 2

[0024] A high-temperature-resistant and wear-resistant coating material for military electronic components proposed by the present invention comprises the following raw materials in parts by weight:

[0025] 40 parts of epoxy resin, 40 parts of polyurethane resin, 4.5 parts of polytetrafluoroethylene micro-powder wax, 1.5 parts of ammonium sulfate, 4 parts of isobutyltriethoxysilane, 6.5 parts of talcum powder, 3.5 parts of nano silicon dioxide, antioxidant 1.5 parts of agent and 1.5 parts of dispersant.

[0026] Its preparation method comprises the following steps:

[0027] S1. According to the specific gravity, add polytetrafluoroethylene micropowder wax and ammonium sulfate into isobutyltriethoxysilane, stir at a speed of 400r / min for 8min, then add talc powder and nano silicon dioxide, and ultrasonically Evenly dispersed mixture A;

[0028] S2. According to the specific gravity, epoxy resin, polyurethane resin, antioxidant, dispersant and the mixture A obtained in step S...

Embodiment 3

[0031] A high-temperature-resistant and wear-resistant coating material for military electronic components proposed by the present invention comprises the following raw materials in parts by weight:

[0032] 50 parts of epoxy resin, 50 parts of polyurethane resin, 8 parts of polytetrafluoroethylene micro-powder wax, 2 parts of ammonium sulfate, 5 parts of isobutyl triethoxysilane, 8 parts of talcum powder, 5 parts of nano silicon dioxide, antioxidant 2 parts of agent and 2 parts of dispersant.

[0033] Its preparation method comprises the following steps:

[0034] S1. According to the specific gravity, add polytetrafluoroethylene micropowder wax and ammonium sulfate into isobutyltriethoxysilane, stir at a speed of 500r / min for 10min, then add talc powder and nano silicon dioxide, and ultrasonically Evenly dispersed mixture A;

[0035] S2. According to the specific gravity, epoxy resin, polyurethane resin, antioxidant, dispersant and the mixture A obtained in step S1 are join...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com