Application of boron-oxygen-containing compound to production of mineral wool

A boron oxide, mineral wool technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of difficult temperature areas, and it is difficult for waste residue to become high-quality mineral fiber raw materials, etc., to reduce melting temperature, improve physical and chemical performance, power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

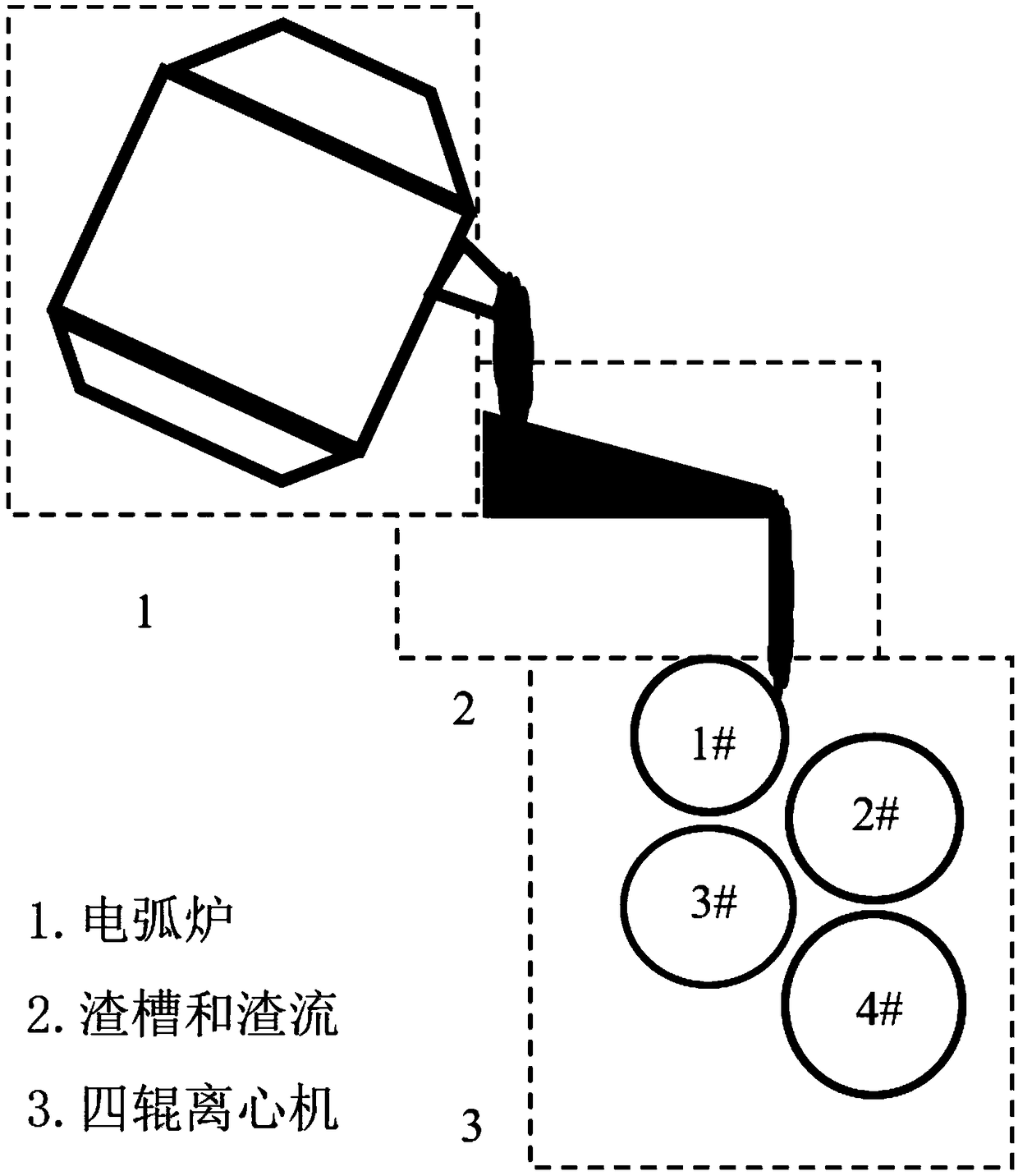

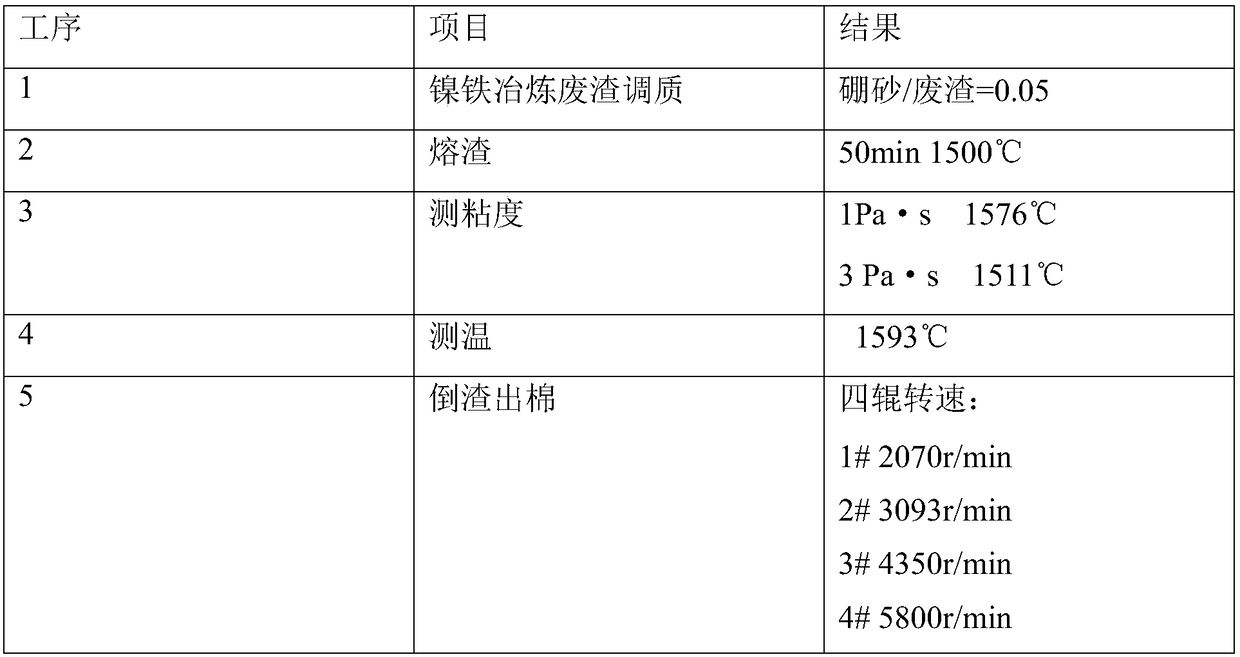

Embodiment 1

[0025] This implementation is aimed at the method of producing mineral wool by using quenched and tempered ferronickel smelting waste residue in a 1t electric arc furnace. Ferronickel smelting waste slag 200kg, borax 10kg, the ratio between borax and waste slag is 0.05; borax and waste slag are mixed evenly and then added to the electric furnace, and the arc is raised to heat up. After 50 minutes, the raw materials are completely melted, and the temperature is measured. After the temperature reaches 1600°C, The electric furnace is turned on to keep warm power. Take 500 g of molten slag, and measure the viscosity value of molten slag in the temperature range of 1600°C-1500°C in a viscometer. After the temperature-viscosity value is suitable, the temperature measured slag is 1593°C; the slag is discharged from the furnace, and the slag is dumped on the rollers of the four-roller centrifuge through the diversion groove, and the four-roller speeds are respectively 1#2070r / min, 2#3...

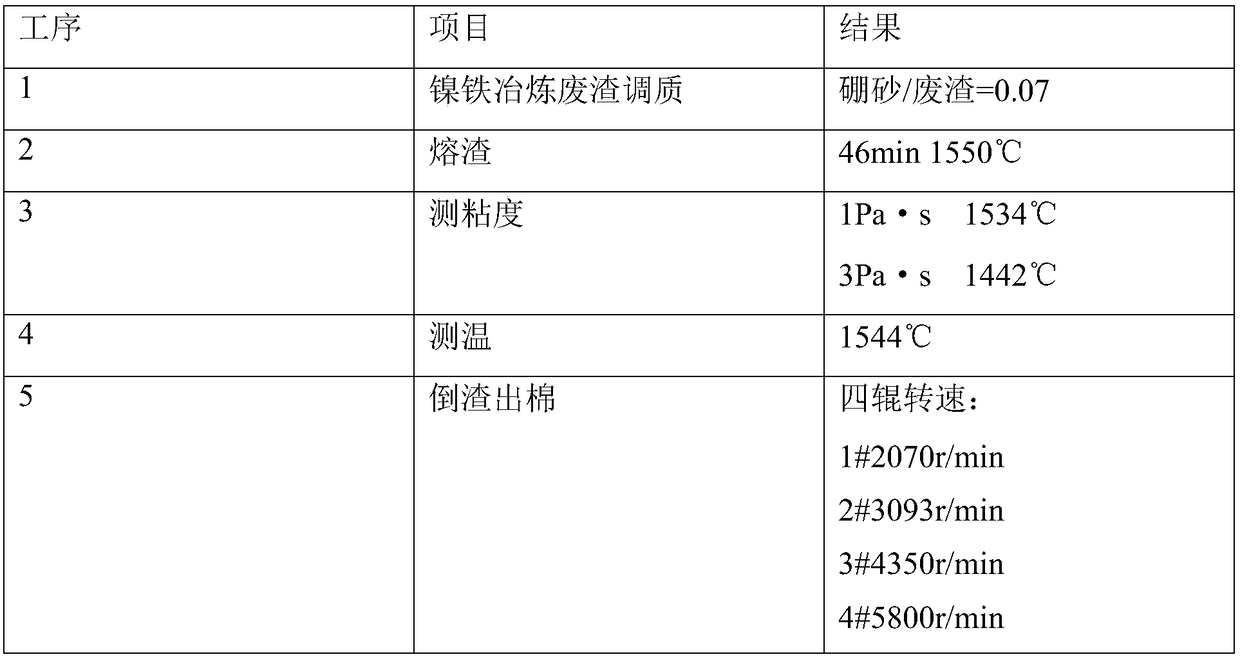

Embodiment 2

[0030] This implementation is aimed at the method of producing mineral wool by using quenched and tempered ferronickel smelting waste residue in a 1t electric arc furnace. Ferronickel smelting waste slag 200kg, borax 14kg, the ratio between borax and waste slag is 0.07; borax and waste slag are mixed evenly and added to the electric furnace, and the arc is raised to heat up. After 46 minutes, the raw materials are completely melted, and the temperature is measured. After the temperature reaches 1550°C, The electric furnace is turned on to keep warm power. Take 500 g of molten slag, and measure the viscosity value of the molten slag in the temperature range of 1550° C. to 1450° C. in a viscometer. After the temperature-viscosity value is appropriate, the temperature measured slag is 1544°C; the slag is discharged from the furnace, and the slag is dumped on the rollers of the four-roller centrifuge through the diversion groove, and the four-roller speeds are respectively 1#2070r...

Embodiment 3

[0035] This implementation is aimed at the method of producing mineral wool by using quenched and tempered ferronickel smelting waste residue in a 1t electric arc furnace. Ferronickel smelting waste slag 200kg, borax 18kg, the ratio between borax and waste slag is 0.09; borax and waste slag are mixed evenly and then added to the electric furnace, and the arc is raised to heat up. After 45 minutes, the raw materials are completely melted, and the temperature is measured. After the temperature reaches 1500 ℃, The electric furnace is turned on to keep warm power. Take 500 g of molten slag, and measure the viscosity value of molten slag in the temperature range of 1500°C-1350°C in a viscometer. After the temperature-viscosity value is suitable, the temperature measured slag is 1498°C; the slag is discharged from the furnace, and the slag is poured on the rollers of the four-roller centrifuge in a flow form through the diversion groove. #3093r / min, 3#4350r / min and 4#5800r / min; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com