Disordered texturing method and device for roller surface optical fiber lasers based on transmission type galvanometer

A roll surface, fiber laser technology is applied in the field of roll surface texturing, which can solve the problems of long mechanical structure and the influence of the working frequency of the galvanometer, and achieve the effect of high working frequency, compact mechanical structure, and improved focusing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

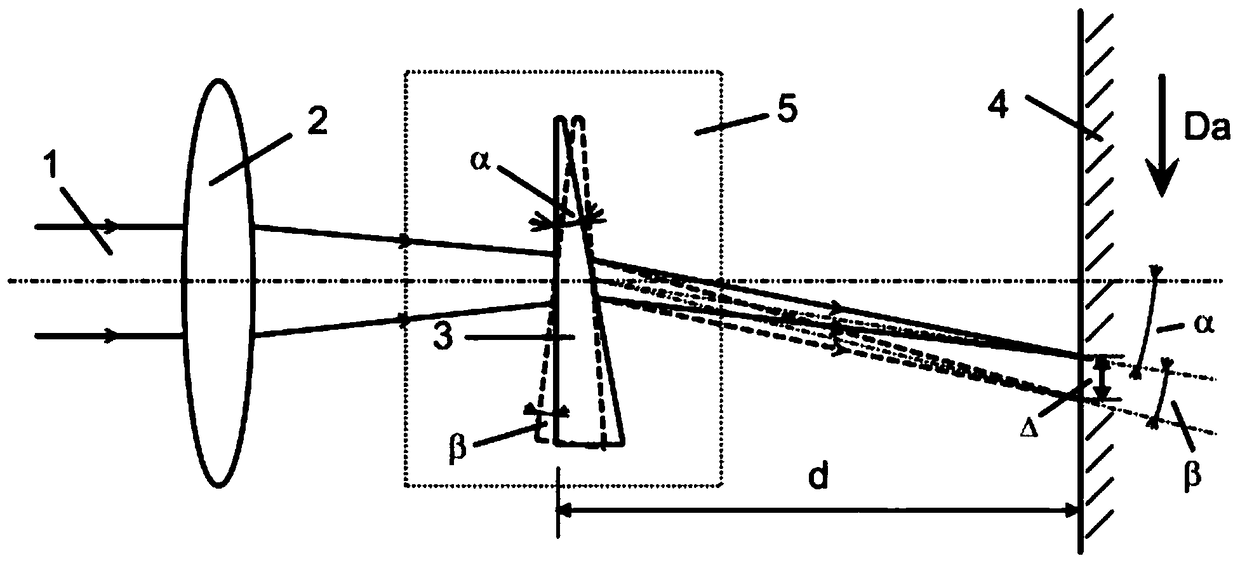

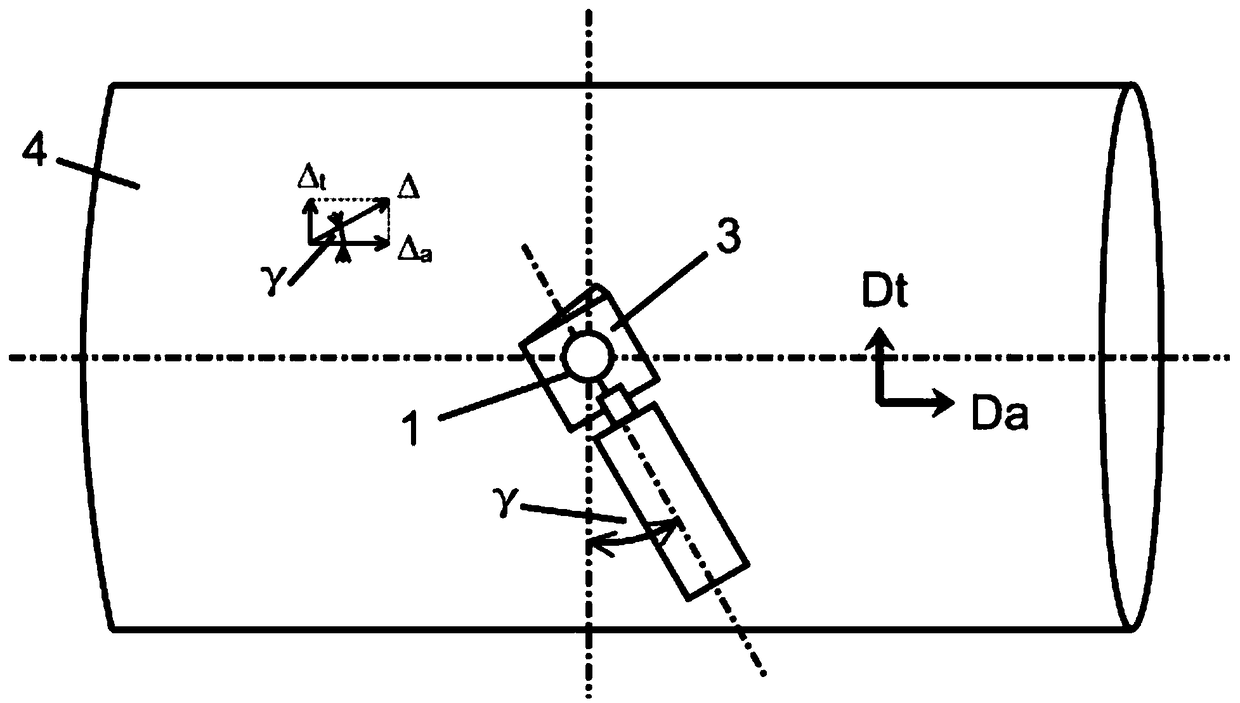

[0040] Such as figure 1 , the present embodiment provides a device and method for optical fiber laser randomization of the roll surface based on a transmission galvanometer, which includes a mechanical mount for installing the galvanometer assembly 5 and the focusing lens 2, and the galvanometer assembly 5 is an independent The vibrating mirror 3, the vibrating mirror 3 includes a motor and a mirror, and the motor drives the mirror to deflect randomly under the action of the control circuit; the focusing lens 2 converges the incident laser beam 1 through the mirror to the surface of the roller 4, wherein the input laser beam 1 The output end of the fiber laser is also installed on the mechanical mount, the mechanical mount is placed on the pallet of the machine tool, the roll 4 is supported on the machine tool and rotates along its own axis through the machine tool, and the frame of the machine tool moves along the axis of the roll 4; The mirror 3 is placed in the laser beam 1...

Embodiment 2

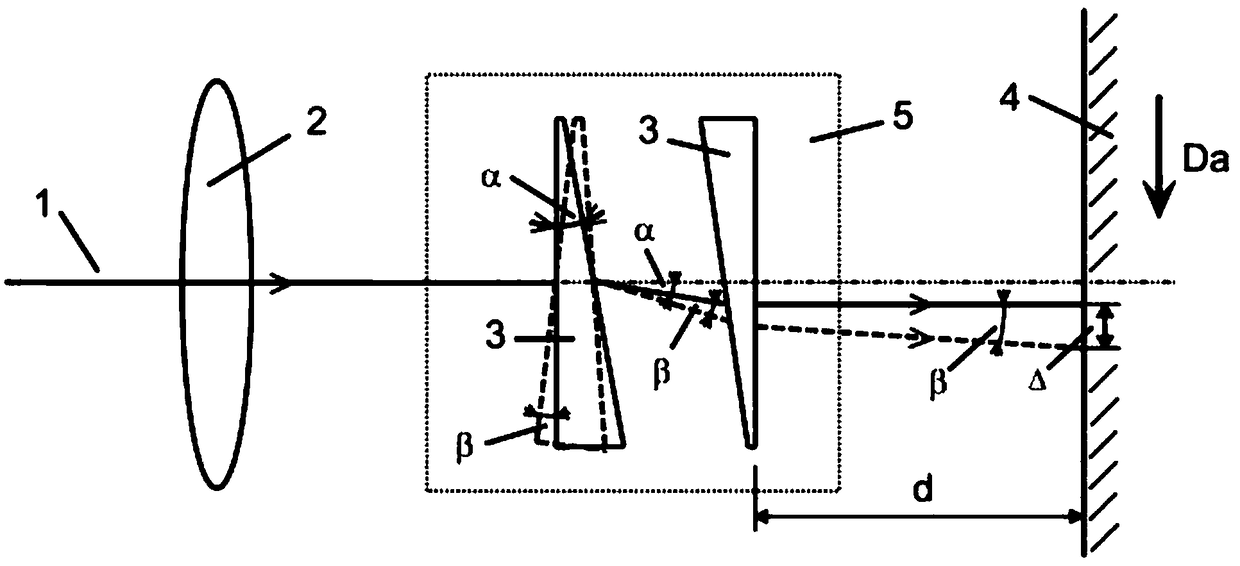

[0052] Such as figure 2 As shown, on the basis of Embodiment 1, the vibrating mirror assembly 5 is composed of two vibrating mirrors 3 and is also placed between the focusing lens 2 and the roll 4 .

[0053] The included angle between the axes of the two vibrating mirrors 3 is 180°, the reference planes of the optical wedges are parallel, and the slopes are opposite; the phase difference of the signals output by the control circuits of the motors of the two vibrating mirrors is 180 degrees, and when one vibrating mirror is working, the other One remained still.

[0054] The process of offsetting the positions of the textured pits on the surface of the roll 4 by the vibrating mirror assembly 5 is similar to that of Example 1 in the first embodiment. By using two vibrating mirrors 3 to form the vibrating mirror assembly 5, the aberration of the transmissive optical wedge can be compensated and the focusing quality can be improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Focal length range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com