Microfluidic paper chip with controllable fluid transportation and its preparation method and use method

A microfluidic paper chip and fluid technology, applied in fluid controllers, chemical instruments and methods, laboratory containers, etc., can solve the problems of a large number of reactant processing procedures, flexible control of difficult fluids, etc., to speed up transportation , Easy to use, the effect of slowing down the speed of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of microfluidic paper chip with controllable fluid transport

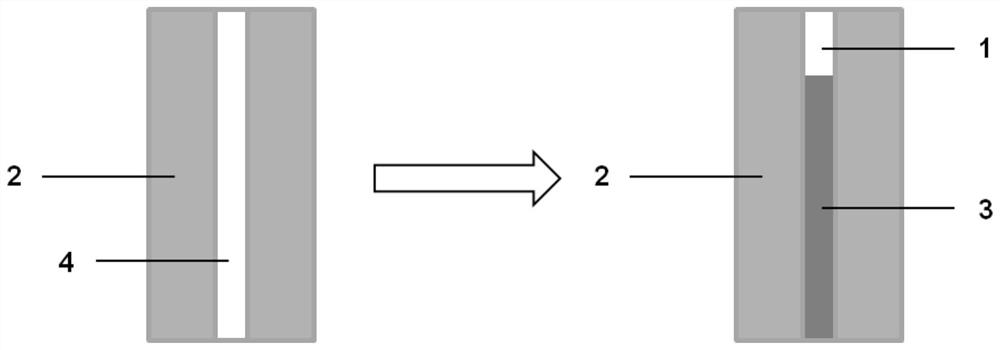

[0030] Such as figure 2 As shown, the preparation method of the above-mentioned microfluidic paper chip, the specific steps are as follows:

[0031] S1. Hydrophobic polymers containing styrene and benzophenone structural units and hydrophilic polymers containing N,N-dimethylacrylamide, spiropyran and benzophenone structural units were synthesized by free radical polymerization ,Specific steps are as follows:

[0032] (1) Synthesize a hydrophobic macromolecule containing styrene and benzophenone structural units by free radical polymerization, and the specific steps are:

[0033] ①Synthesis of benzophenone monomer. Dissolve 25.0g of 4-hydroxybenzophenone, 13.9g of methacryloyl chloride and 13.6g of triethylamine in 300mL of dichloromethane, react at room temperature for 24h, filter, and wash the organic phase with 200mL hydrochloric acid solution (0.1M), 200mL Distilled water, 200m...

Embodiment 2

[0042] Example 2: Preparation of microfluidic paper chip with controllable fluid transport

[0043] Different from embodiment 1 is step S2 and step S3, specifically as follows:

[0044] S2. Prepare the hydrophobic polymer containing styrene and benzophenone structural units synthesized in step S1 into a 50 mg / mL tetrahydrofuran solution, soak the filter paper in the solution, take it out and dry it, and put it into a UV curing box for ultraviolet light Curing (ultraviolet wavelength is 365nm, required energy is 10J / cm 2 ), and use a light shield to cover the middle part of the filter paper during the UV curing process, and then use a Soxhlet extractor to wash the hydrophobic polymer in the non-irradiated part, so as to construct the barrier area 2 and the hydrophilic channel 4 on the filter paper.

[0045] S3. The hydrophilic polymer containing N,N-dimethylacrylamide, spiropyran and benzophenone structural units synthesized in step S1 is formulated into 30mg / mL acetone soluti...

Embodiment 3

[0046] Example 3: Preparation of microfluidic paper chip with controllable fluid transport

[0047] Different from Embodiment 1 and 2 are step S2 and step S3, specifically as follows:

[0048] S2. Prepare the hydrophobic polymer containing styrene and benzophenone structural units synthesized in step S1 into a 100 mg / mL tetrahydrofuran solution, soak the filter paper in the solution, take it out and dry it, and put it into a UV curing box for ultraviolet light Curing (ultraviolet wavelength is 365nm, required energy is 20J / cm 2 ), and use a light shield to cover the middle part of the filter paper during the UV curing process, and then use a Soxhlet extractor to wash the hydrophobic polymer in the non-irradiated part, so as to construct the barrier area 2 and the hydrophilic channel 4 on the filter paper.

[0049] S3. The hydrophilic polymer containing N,N-dimethylacrylamide, spiropyran and benzophenone structural units synthesized in step S1 is prepared into a 50 mg / mL chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com