A kind of supported catalyst and its preparation method and application

A supported catalyst, ceramic carrier technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Achieve the effect of improving activity and stability, not easy to drop powder and cracking, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

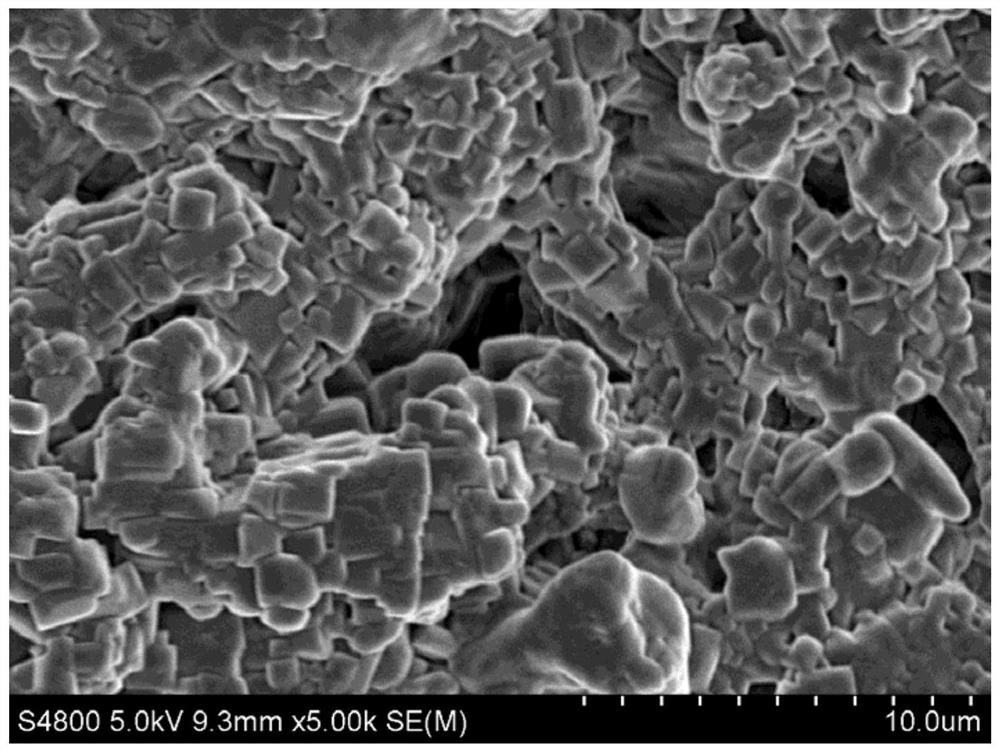

[0035] (1) 500g of Al(NO 3 ) 3 9H 2 O was added to 1L of secondary water and dissolved completely. Take a cordierite honeycomb ceramic carrier with a volume size of 100mm×100mm×50mm (the SEM image of which is shown in figure 1 shown, from figure 1 It can be seen that the carrier has a microporous structure, and the cyanite pore structure is obvious, and it is composed of many tiny particles of 1-5 μm) dried at 100°C for 2.0h, and completely impregnated into the prepared Al(NO 3 ) 3 In the aqueous solution, the immersion time is 10min. impregnated Al(NO 3 ) 3 After the aqueous solution, the cordierite honeycomb ceramic carrier was taken out, and the excess solution inside the pores of the cordierite honeycomb ceramic carrier was blown off with an ear washing ball, then placed in an oven and dried at 120°C for 2.0h, and then transferred to a muffle furnace Calcined at 400°C for 4.0h.

[0036] (2) 86.82g of Ce(NO 3 ) 3 9H 2 O was added to 1L of secondary water and dis...

Embodiment 2

[0042] (1) 500g of Al(NO 3 ) 3 9H 2 O was added to 1L of secondary water and dissolved completely. A cordierite honeycomb ceramic carrier with a volume size of 100mm×100mm×50mm was dried at 100°C for 2.0h, and it was completely impregnated into the prepared Al(NO 3 ) 3 In the aqueous solution, the immersion time is 10min. Impregnated Al(NO 3 ) 3 After the aqueous solution, the cordierite honeycomb ceramic carrier was taken out, and the excess solution inside the pores of the cordierite honeycomb ceramic carrier was blown off with an ear washing ball, then placed in an oven and dried at 120°C for 2.0h, and then transferred to a muffle furnace Calcined at 500°C for 4.0h.

[0043] (2) 71.60g of 50% Mn (NO 3 ) 2 Add to 1L of secondary water and dissolve completely. The load obtained in step (1) has Al 2 o 3 The cordierite is completely impregnated in it, and the impregnation time is 10min. Impregnated Mn(NO 3 ) 2 After the aqueous solution, the cordierite was taken ...

Embodiment 3

[0047] (1) 500g of Al(NO3 ) 3 9H 2 O was added to 1L of secondary water and dissolved completely. A cordierite honeycomb ceramic carrier with a volume size of 100mm×100mm×50mm was dried at 100°C for 2.0h, and it was completely impregnated into the prepared Al(NO 3 ) 3 In the aqueous solution, the immersion time is 10min. Impregnated Al(NO 3 ) 3 After the aqueous solution, the cordierite honeycomb ceramic carrier was taken out, and the excess solution inside the pores of the cordierite honeycomb ceramic carrier was blown off with an ear washing ball, then placed in an oven and dried at 120°C for 2.0h, and then transferred to a muffle furnace Calcined at 400°C for 4.0h.

[0048] (2) 78.14g of Ce(NO 3 ) 3 9H 2 O and 7.16g of 50wt% Mn(NO 3 ) 2 Add to 1L of secondary water and dissolve completely. The load obtained in step (1) has Al 2 o 3 The cordierite is completely impregnated in it, and the impregnation time is 10min. Impregnated Ce(NO 3 ) 3 and Mn(NO 3 ) 2 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com