Anti-allergic pressure sensitive adhesive for medical bandages, and preparation method of anti-allergic pressure sensitive adhesive

A technology of allergy pressure-sensitive adhesives and bandages, applied in bandages, medical science, absorbent pads, etc., can solve problems such as allergies, itching, troubled patients, etc., and achieve the effect of enhanced peel strength and moderate peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

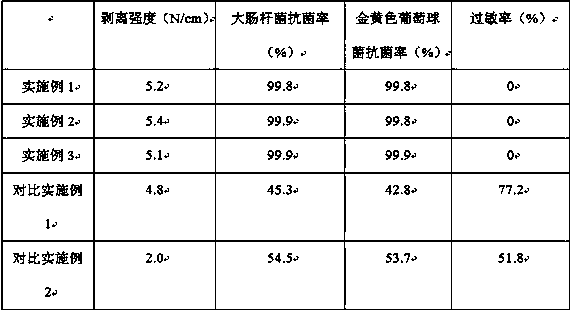

Examples

Embodiment 1

[0020] An antiallergic pressure-sensitive adhesive for medical bandages, comprising the following raw materials by weight:

[0021] Chinese herbal medicine extract 10, chitosan 10, acetic acid solution 4, gallic acid 3, polyvinyl alcohol 5, methacrylic acid 40, initiator BPO 0.58;

[0022] The mass concentration of the acetic acid solution is 2%.

[0023] Further, its preparation method comprises the following steps:

[0024] (1) Add chitosan to the traditional Chinese medicine extract, heat to 70°C, add acetic acid solution dropwise, and stir at 300rpm for 3 hours, let it stand for defoaming, and carry out wet spinning at 25°C to obtain Ice water is used as a coagulation bath, the fibers are collected and spun, and crushed to a particle size of less than 50 μm;

[0025] (2) Add gallic acid into distilled water 10 times its volume, heat to boiling, stir and dissolve at 300rpm, then cool down to 85°C, add polyvinyl alcohol to it, continue stirring for 20min, and then add meth...

Embodiment 2

[0031] An antiallergic pressure-sensitive adhesive for medical bandages, comprising the following raw materials by weight:

[0032] Chinese herbal medicine extract 20, chitosan 15, acetic acid solution 5, gallic acid 4, polyvinyl alcohol 7, methacrylic acid 45, initiator BPO 0.7;

[0033] The mass concentration of the acetic acid solution is 3%.

[0034] Further, its preparation method comprises the following steps:

[0035] (1) Add chitosan to the traditional Chinese medicine extract, heat to 80°C, add acetic acid solution dropwise, stir and react at 400rpm for 4h, let it stand for defoaming, and carry out wet spinning at 27°C to obtain Ice water is used as a coagulation bath, the fibers are collected and spun, and crushed to a particle size of less than 50 μm;

[0036] (2) Add gallic acid into distilled water 15 times its volume, heat to boiling, stir and dissolve at 400rpm, then cool down to 90°C, add polyvinyl alcohol to it, continue stirring for 25min, and then add meth...

Embodiment 3

[0042] An antiallergic pressure-sensitive adhesive for medical bandages, comprising the following raw materials by weight:

[0043] Chinese herbal medicine extract 30, chitosan 20, acetic acid solution 8, gallic acid 5, polyvinyl alcohol 10, methacrylic acid 50, initiator BPO 0.8;

[0044] The mass concentration of the acetic acid solution is 5%.

[0045] Further, its preparation method comprises the following steps:

[0046] (1) Add chitosan to the traditional Chinese medicine extract, heat to 85°C, add acetic acid solution dropwise, stir and react at 500rpm for 4h, let it stand for defoaming, and carry out wet spinning at 28°C to obtain Ice water is used as a coagulation bath, the fibers are collected and spun, and crushed to a particle size of less than 50 μm;

[0047] (2) Add gallic acid into distilled water 20 times its volume, heat to boiling, stir and dissolve at 500rpm, then cool down to 94°C, add polyvinyl alcohol to it, continue stirring for 30min, and then add met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com