Modified sodium alginate, preparation method thereof, pressure-sensitive adhesive and patch

A technology of sodium alginate and pressure-sensitive adhesive, which is applied in its preparation, modified sodium alginate, pressure-sensitive adhesive and patches, can solve the problems of good skin affinity and moderate peel strength, and achieve good skin affinity, Good bonding stability, the effect of reducing the risk of skin allergies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

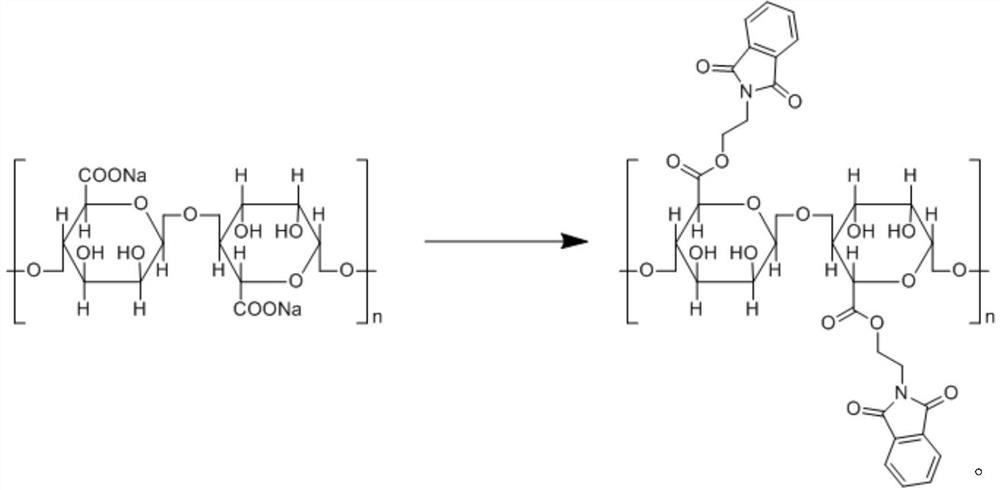

[0018] As described in the background art, the existing patch has the problem that it cannot satisfy both good skin affinity and moderate peel strength. In order to solve the above-mentioned technical problems, the application provides a preparation method of modified sodium alginate. The preparation method of modified sodium alginate comprises: mixing sodium alginate with lye to obtain sodium alginate solution; making sodium alginate The solution is grafted with N-(2-chloroethyl)phthalimide to obtain modified sodium alginate.

[0019] Sodium alginate is a by-product of extracting iodine and mannitol from brown algae kelp or sargassum. It is a natural polysaccharide with the stability, solubility, viscosity and safety required for pharmaceutical excipients. Sodium alginate is soluble in water but insoluble in organic solvents such as ethanol, ether, and chloroform. The aqueous solution of sodium alginate has a high viscosity and has been used as a thickener, stabilizer, and em...

Embodiment 1

[0036] A breathable medical temperature-controlled hot compress, including a non-woven bag, a heating layer arranged inside the non-woven bag, and a pressure-sensitive tape for fixing the non-woven bag. The pressure-sensitive tape is made of a pressure-sensitive adhesive with a thickness of 35 μm and Composition of release paper.

[0037] The preparation method of pressure-sensitive adhesive is as follows:

[0038] (1) 47g of sodium alginate was heated and dissolved in an aqueous solution of sodium hydroxide having a mass concentration of 5% at 60° C. to obtain a sodium alginate solution.

[0039] (2) 48 g of N-(2-chloroethyl)phthalimide was dissolved in tetrahydrofuran to obtain N-(2-chloroethyl)phthalimide solution.

[0040] (3) Add N-(2-chloroethyl)phthalimide solution dropwise to the sodium alginate solution, heat to 70°C, keep stirring and react for 8 hours, let it stand for stratification, take the water phase, concentrate and remove water , to obtain modified alginic ...

Embodiment 2

[0043] A breathable medical temperature-controlled hot compress, including a non-woven bag, a heating layer arranged inside the non-woven bag, and a pressure-sensitive tape for fixing the non-woven bag. The pressure-sensitive tape is made of a pressure-sensitive adhesive with a thickness of 35 μm and Composition of release paper.

[0044] The preparation method of pressure-sensitive adhesive is as follows:

[0045] (1) 47g of sodium alginate was heated and dissolved in an aqueous solution of sodium hydroxide having a mass concentration of 5% at 60° C. to obtain a sodium alginate solution.

[0046] (2) 52 g of N-(2-chloroethyl)phthalimide was dissolved in tetrahydrofuran to obtain N-(2-chloroethyl)phthalimide solution.

[0047] (3) Add N-(2-chloroethyl)phthalimide solution dropwise to the sodium alginate solution, heat to 70°C, keep stirring and react for 8 hours, let it stand for stratification, take the water phase, concentrate and remove water , to obtain modified alginic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com