Mesoporous silica nanoparticles modified by nucleic acid aptamer targeting polyethylene glycol and preparation method thereof

A mesoporous silica and nucleic acid aptamer technology, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, active ingredients of heterocyclic compounds, etc., can solve problems such as easy aggregation, precipitation, and large particle size, and achieve Good biocompatibility, improved water dispersibility and sustained release ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of mesoporous silica nanoparticles

[0030] 1. Dissolve 0.1 g of CTAB in 70 mL of water, 1 mL of ammonia water, and stir at room temperature for 15 minutes; the mass percent concentration of the ammonia water is 25%.

[0031] 2. Add 0.6 mL TEOS dropwise to the product of step 1 with vigorous stirring, and stir for 5 hours.

[0032] 3. Precipitate overnight at room temperature.

[0033] 4. Collect the precipitate by centrifugation and wash four times with ethanol.

[0034] 5. Vacuum dry at 100°C overnight, then calcined at 550°C for 6 hours to obtain mesoporous silica.

Embodiment 2

[0036] 2. Preparation of polyethylene glycol-modified mesoporous silica

[0037] 1. Add 100 mg mesoporous silica to 50 mL ethanol solution containing 25 uL APTES, stir at room temperature for 24 hours.

[0038] 2. Collect the precipitate by centrifugation and wash four times with ethanol.

[0039] 3. Vacuum drying at 80°C overnight to obtain mesoporous silica with surface-modified amine groups.

[0040] 4. The amine-modified mesoporous silica and amine-polyethylene glycol-carboxyl were reacted in PBS (pH 7.4) containing 10 mMEDC and 10 mM NHS in a molar ratio of 1:1 and stirred at room temperature for 2 to 4 hours.

[0041] In step 4 above, the amine groups of the amine-modified mesoporous silica need to be quantified, and the amine-modified mesoporous silica is dispersed in a 0.02 M sodium hydroxide solution and stirred for 60 hours. The supernatant (containing cleaved APTES) was taken to detect amine groups. The supernatant was mixed with PBS (0.2 M, pH 8), then 140 uL of...

Embodiment 3

[0043] 3. Preparation of PEG-modified mesoporous silica nanoparticles targeted by nucleic acid aptamers

[0044] 1. Centrifuge at 15,000 rpm for 10 minutes, and the precipitate is dispersed in PBS (pH 7.4) containing EDC and NHS. Add the terminal carboxyl-modified AS1411 nucleic acid aptamer and stir at room temperature for 24 hours.

[0045] 2. Centrifuge at 15,000 rpm for 10 minutes to obtain mesoporous silica-polyethylene glycol-nucleic acid aptamer nanoparticles.

[0046] 3. The obtained sample is analyzed by infrared spectroscopy and the nanometer particle size is measured.

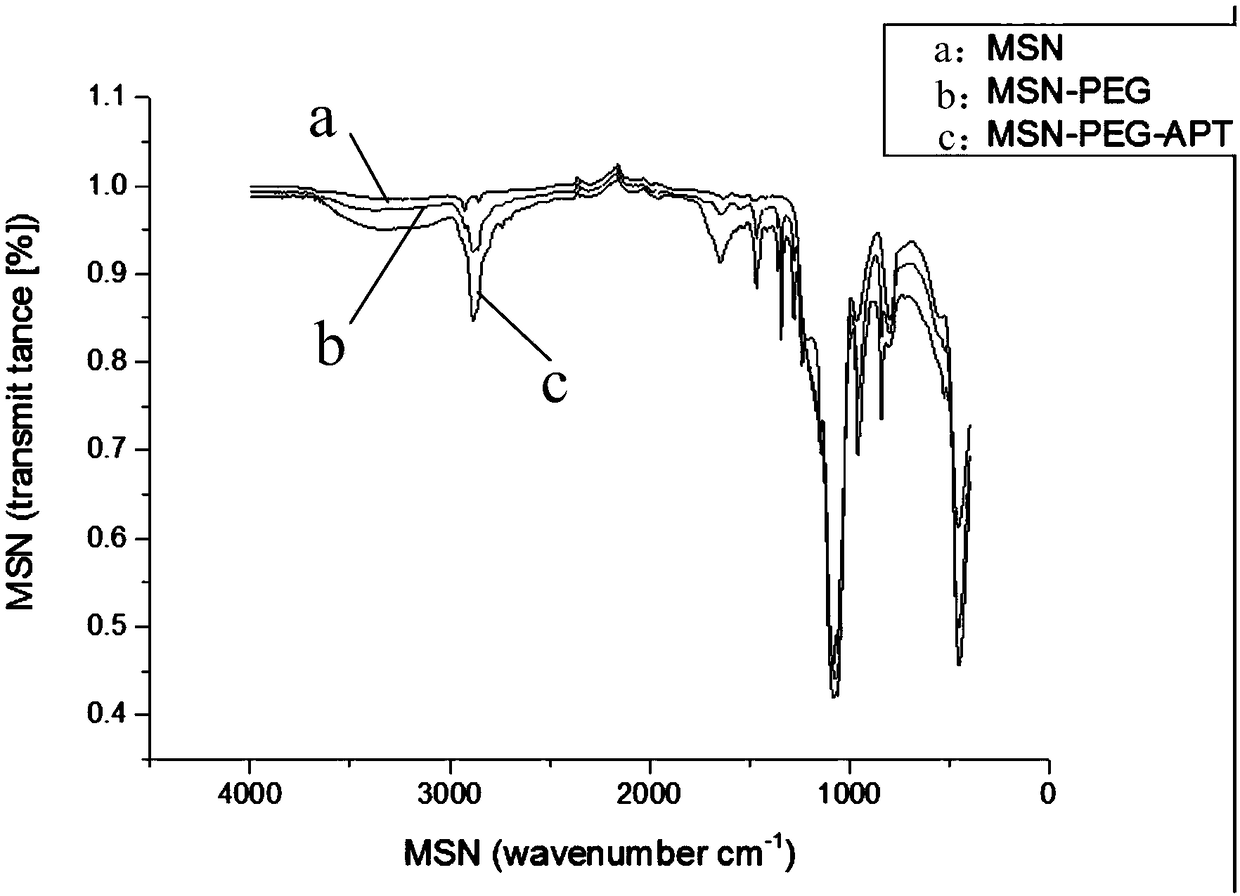

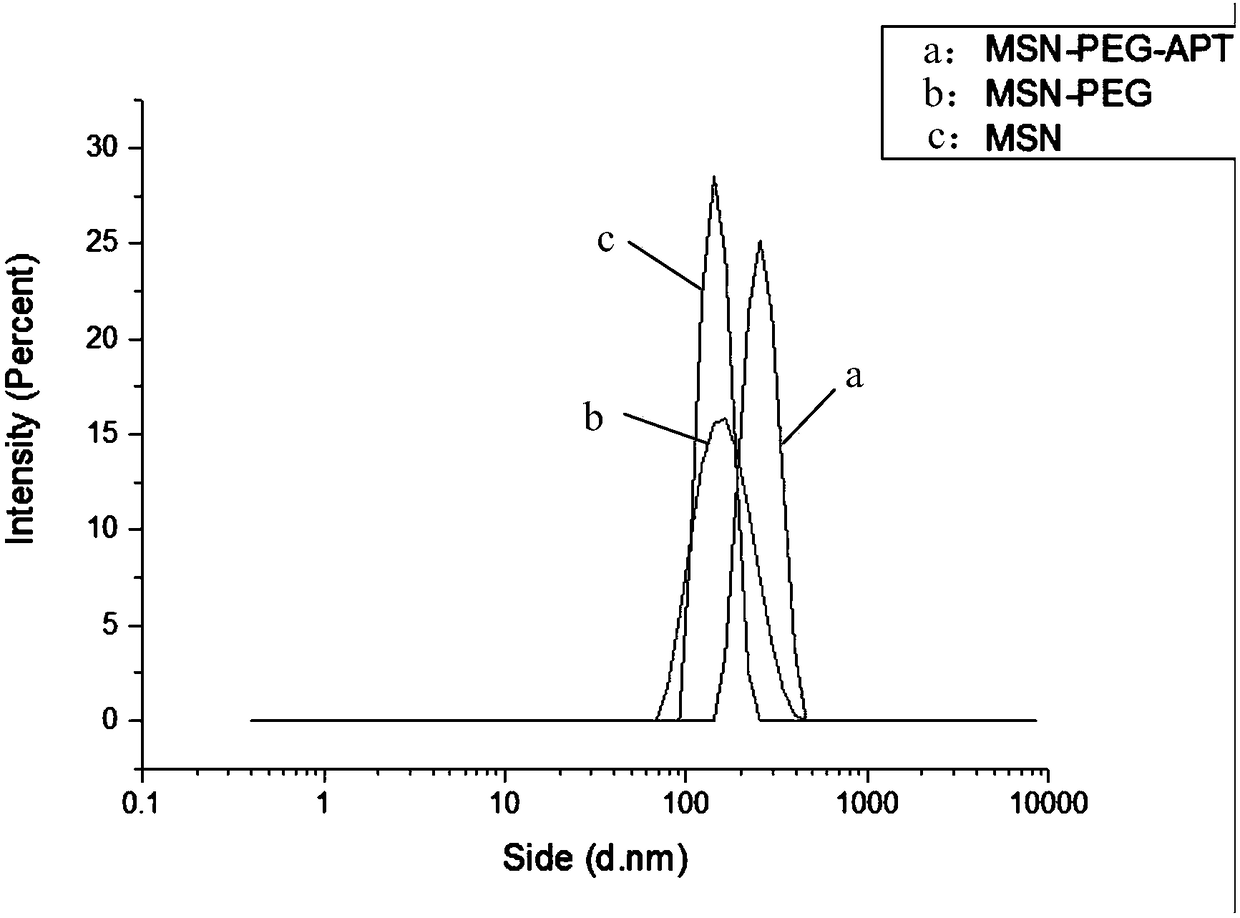

[0047] figure 1 In order to react the amino-activated MSN with the carboxyl-activated PEG, MSN and PEG are generated through dehydration condensation, and the positions of the amide group or the external characteristic peaks are 3000cm-1 and 1689.0cm-1; so MSN-PEG (line b) and Compared with MSN (line a), the intensity of the peaks at the positions of 3000cm-1 and 1689.0cm-1 is obviously enhanced. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com