Sensorless model predictive control system and method for vehicle permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and sensor model, which is applied in control system, motor control, vector control system, etc., to achieve the effect of realizing performance, good system robustness, and preventing too fast change frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

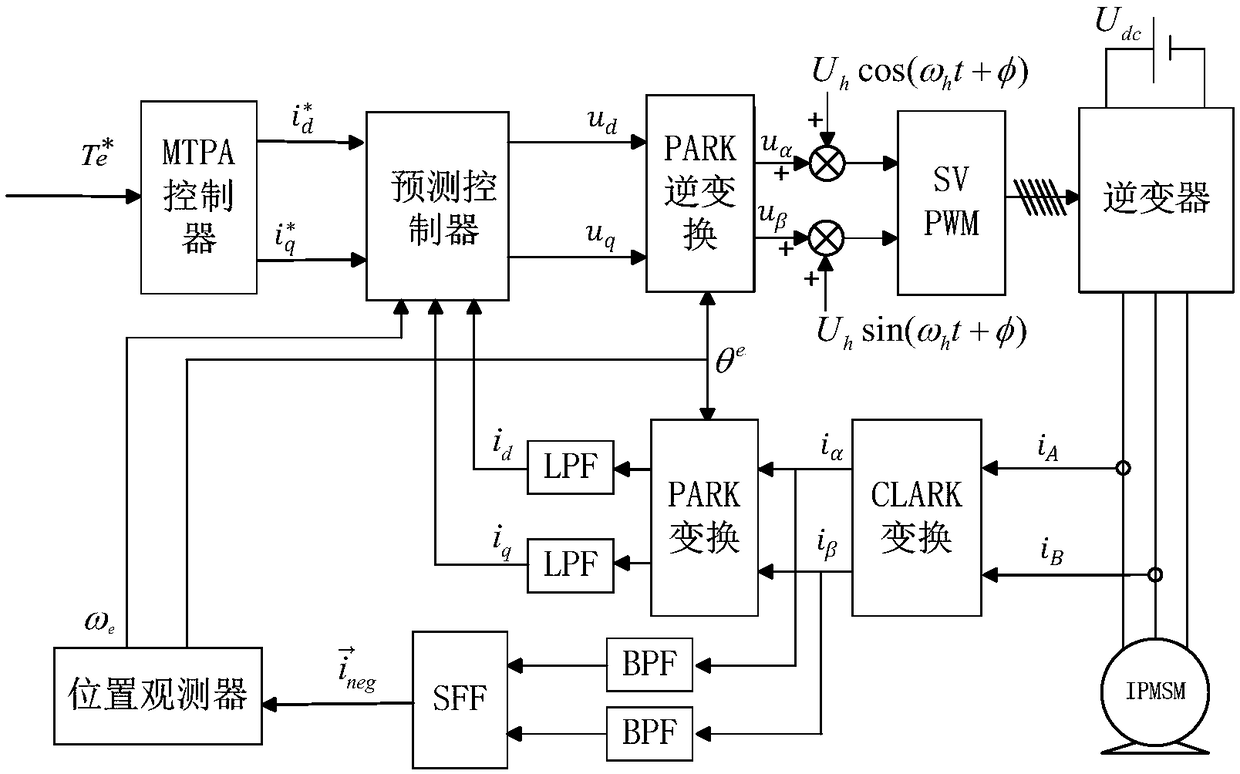

[0045] Such as figure 1 As shown, a position sensorless model predictive control system for permanent magnet synchronous motors for vehicles, the system includes:

[0046] Maximum torque current ratio controller (MTPA controller): obtain the stator current reference value according to the torque reference value of the permanent magnet synchronous motor;

[0047] Stator current feedback module: obtain the stator current feedback value of the permanent magnet synchronous motor;

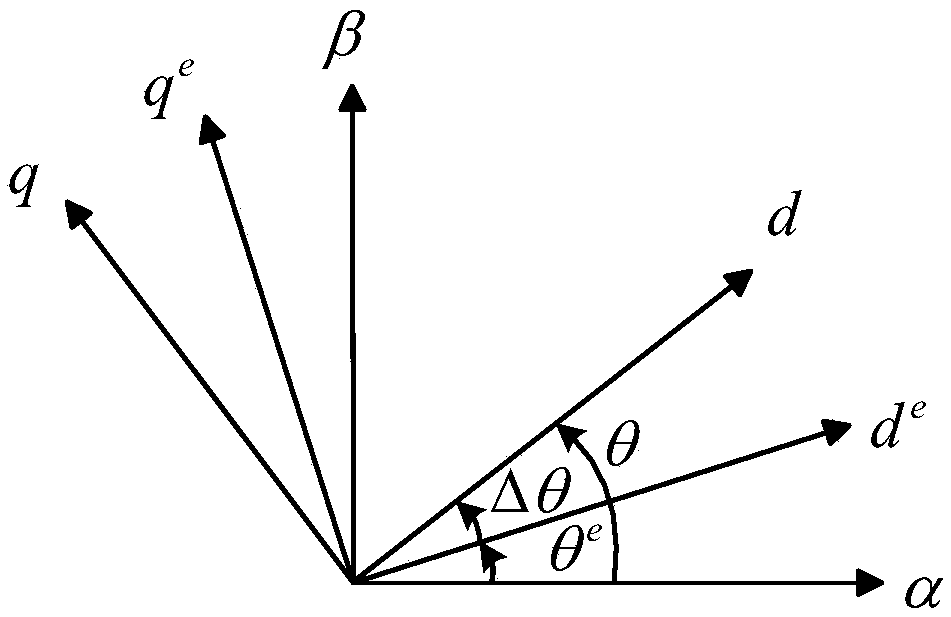

[0048] Position observer module: observe the permanent magnet synchronous motor speed and rotor position angle;

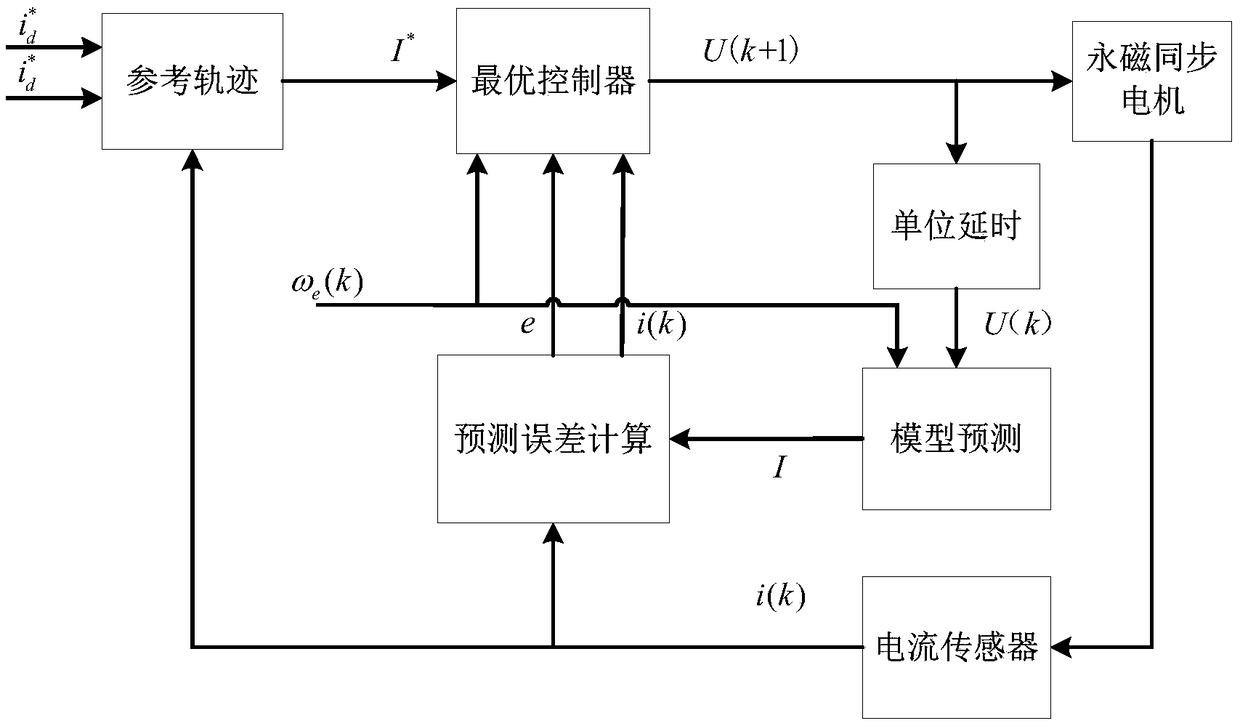

[0049] Current predictive control module: perform current predictive control and output stator voltage reference value according to stator current reference value, stator current feedback value, permanent magnet synchronous motor speed and rotor position;

[0050] Rotary high-frequency voltage injection module: generate a rotating high-frequency voltage signal and superimpose it with the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com