A kind of gel polymer electrolyte diaphragm, lithium ion battery and preparation method thereof

A technology of electrolyte diaphragm and gel polymer, which is applied in the field of lithium-ion batteries, can solve the problems of high production cost, low liquid absorption rate, poor ion conductivity, etc., and achieve low production cost, strong liquid absorption, and high adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

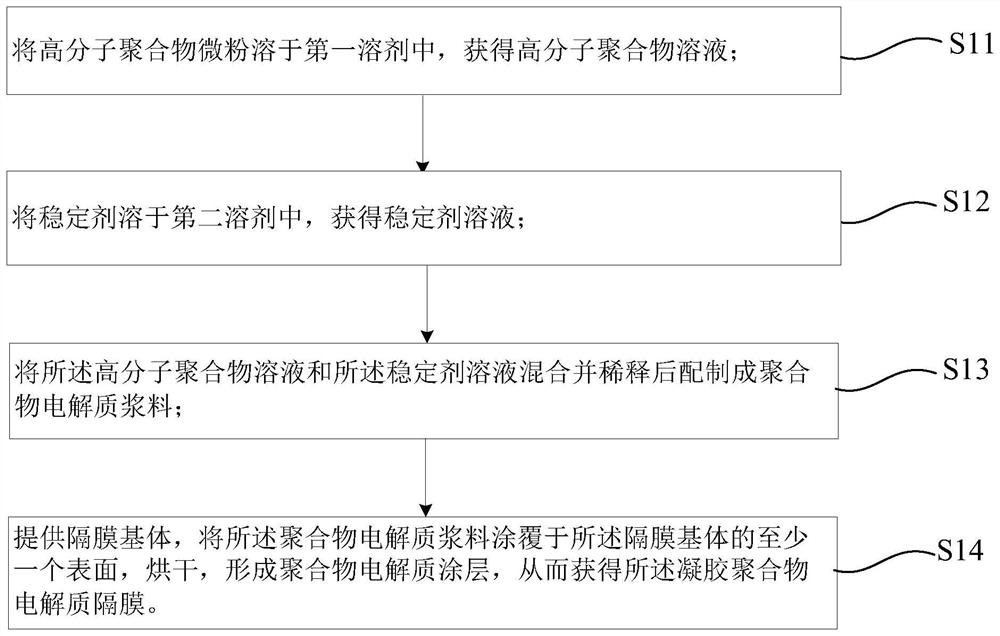

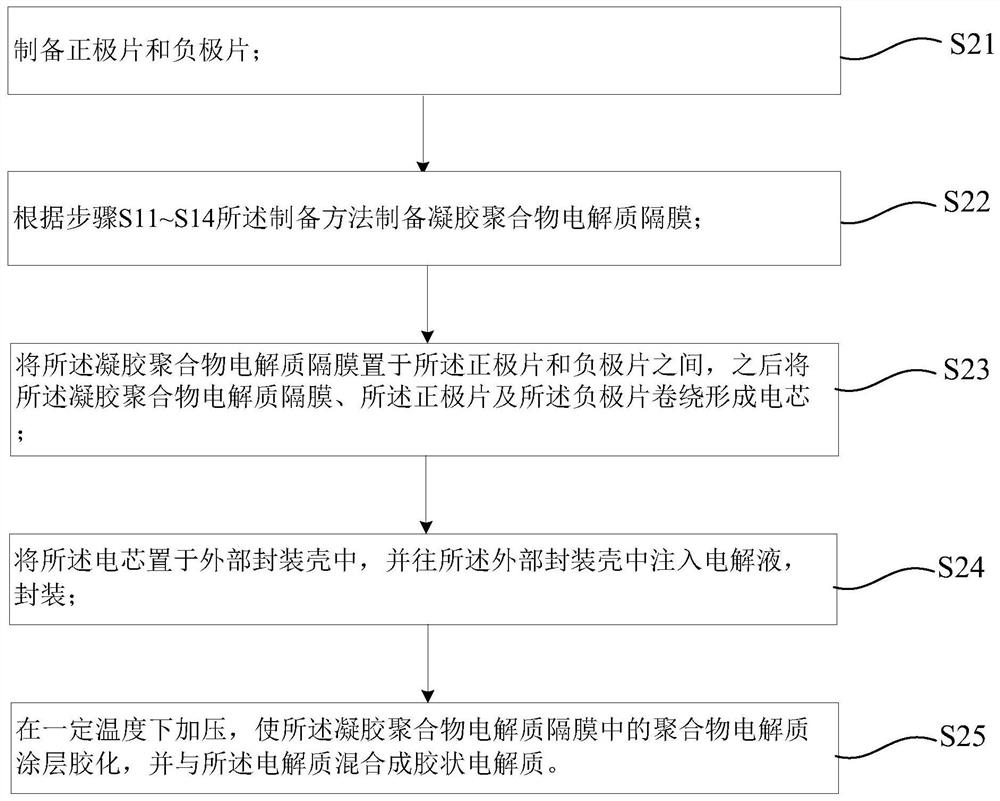

[0032] Such as figure 1 As shown, the present invention provides a kind of preparation method of gel polymer electrolyte membrane, and described preparation method comprises the following steps at least:

[0033] First, step S11 is performed, dissolving the high molecular polymer powder in the first solvent to obtain a high molecular polymer solution.

[0034] As an example, the polymer micropowder includes one of polyvinyl alcohol and polyethylene oxide.

[0035] The high molecular polymer micropowder is a soluble high molecular micropowder, and its function is to absorb the electrolyte to form an ion-conducting gel polymer.

[0036] As an example, the first solvent includes deionized water. Certainly, in other embodiments, other suitable solvent types may also be used, but for environmental protection, deionized water is preferably used as the first solvent.

[0037] Then execute step S12, dissolving the stabilizer in the second solvent to obtain a stabilizer solution.

...

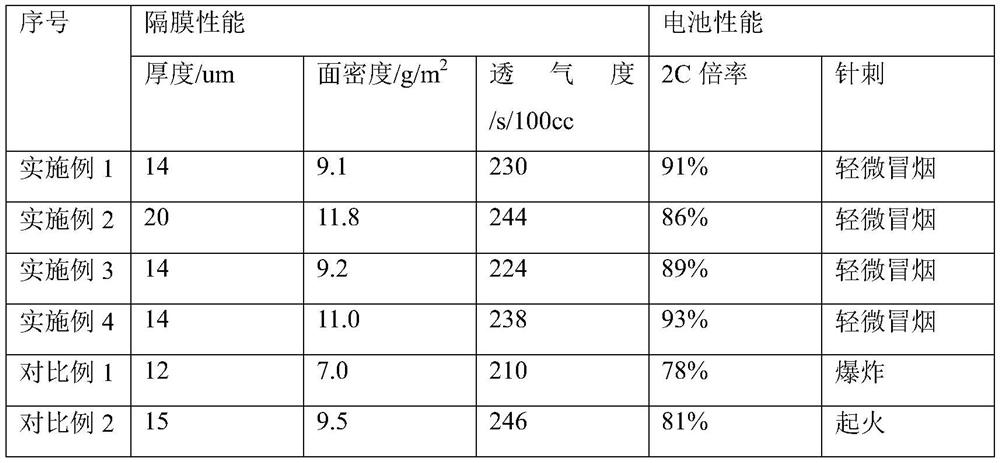

Embodiment 1

[0070] Preparation of gel polymer electrolyte separator:

[0071] Preparation of polymer micropowder solution: 50 g of polyvinyl alcohol was added to 950 g of deionized water, and stirred for 30 minutes to form a polyvinyl alcohol solution.

[0072] Stabilizer solution preparation: Add 20 g of sodium carboxymethyl cellulose to 980 g of deionized water and stir for 90 minutes to form a sodium carboxymethyl cellulose solution.

[0073] Take the above 500g polyvinyl alcohol solution and mix it with 150g sodium carboxymethylcellulose solution, then add deionized water and stir for 30 minutes to form a polymer electrolyte slurry.

[0074] Then, the prepared polymer electrolyte slurry was coated on a 12um substrate PE separator by gravure transfer coating, and dried in an oven to form a 2um-thick coating on one side of the gel polymer electrolyte separator.

[0075] Preparation of positive electrode sheet: Add lithium cobalt oxide, conductive carbon, and binder polyvinylidene fluor...

Embodiment 2

[0080] The processes of positive electrode sheet, negative electrode sheet, non-aqueous electrolyte, and cell molding are the same as in Example 1, but the gel polymer electrolyte separator is prepared by the following method:

[0081] Preparation of polymer micropowder solution: 50 g of polyvinyl alcohol was added to 950 g of deionized water, and stirred for 30 minutes to form a polyvinyl alcohol solution.

[0082] Stabilizer solution preparation: Add 20 g of sodium carboxymethyl cellulose to 980 g of deionized water and stir for 90 minutes to form a sodium carboxymethyl cellulose solution.

[0083] Take the above 500g polyvinyl alcohol solution and mix it with 50g sodium carboxymethylcellulose solution, then add deionized water and stir for 30 minutes to form a polymer electrolyte slurry.

[0084] Then, the prepared polymer electrolyte slurry is coated on a 14um base PE separator by gravure transfer coating, and then dried in an oven to form a double-sided coated gel polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com