Novel multi-sleeve integrated rapid demounting and mounting heat exchanger

A heat exchanger and casing technology, applied in the field of new casing heat exchangers, can solve the problems of corrosion-resistant materials that cannot be produced normally, maintenance, cleaning and disassembly difficulties, and leakage of detachable joints, etc., so as to solve the problem of tube sheet scrapping Problems, compact structure, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

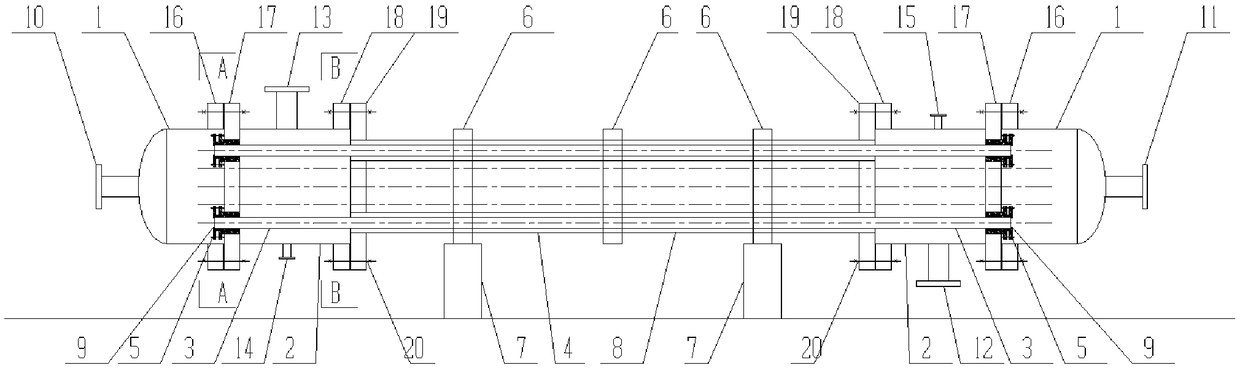

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] Such as figure 1 as shown, figure 1 is a schematic diagram of the present invention. Including 1-inner tube box; 2-outer tube box; 3-inner tube pass; 4-outer tube pass; 5-stuffing box sealing structure; 6-outer tube positioning plate; 7-support; 8-support fins; 9-gland positioning stopper; 10, 11-inner pipe pass inlet and outlet nozzle; 12, 13-outer pipe pass inlet and outlet nozzle; 14-clean discharge port; 15-exhaust port; 16-inner pipe box flange; 17-outer tube box flange 1 and inner tube tube sheet; 18-outer tube box flange 2; 19-outer tube box tube plate; 20-flange connection fasteners and gaskets.

[0029] When working, the medium in the inner tube flows in from the 10-nozzle and is distributed into each inner tube through the 1-inner tube box; flow out to complete the heat exchange. The medium of the outer tube pass flows into each outer tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com