Preparation method of Fe-based amorphous alloy magnetic core and Fe-based amorphous alloy

A technology of iron-based amorphous alloys and magnetic cores, which is applied in the field of preparation of iron-based amorphous alloys and iron-based amorphous alloy magnetic cores, and can solve the problems of long annealing time, high crystallization annealing temperature, and difficult application of magnetic cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Aiming at the problem of constant magnetic permeability of iron-based amorphous alloys prepared in the prior art, this application provides a method for preparing iron-based amorphous alloy magnetic cores, which improves the saturation magnetic induction of the iron-based amorphous alloys. It has better constant magnetic permeability performance in a wider magnetic field. Specifically, the embodiment of the present invention discloses a method for preparing an iron-based amorphous alloy magnetic core, which includes the following steps:

[0035] A) Batching according to the composition of the iron-based amorphous alloy as shown in formula (I), smelting the batched raw materials into molten steel; adjusting the temperature of the molten steel to 150-300°C above the alloy liquidus temperature, The liquid level height of the molten steel is 600-850mm;

[0036] B) Set the copper roller linear speed to 20-30m / s, the distance between the nozzle and the copper roller 200-300μm, an...

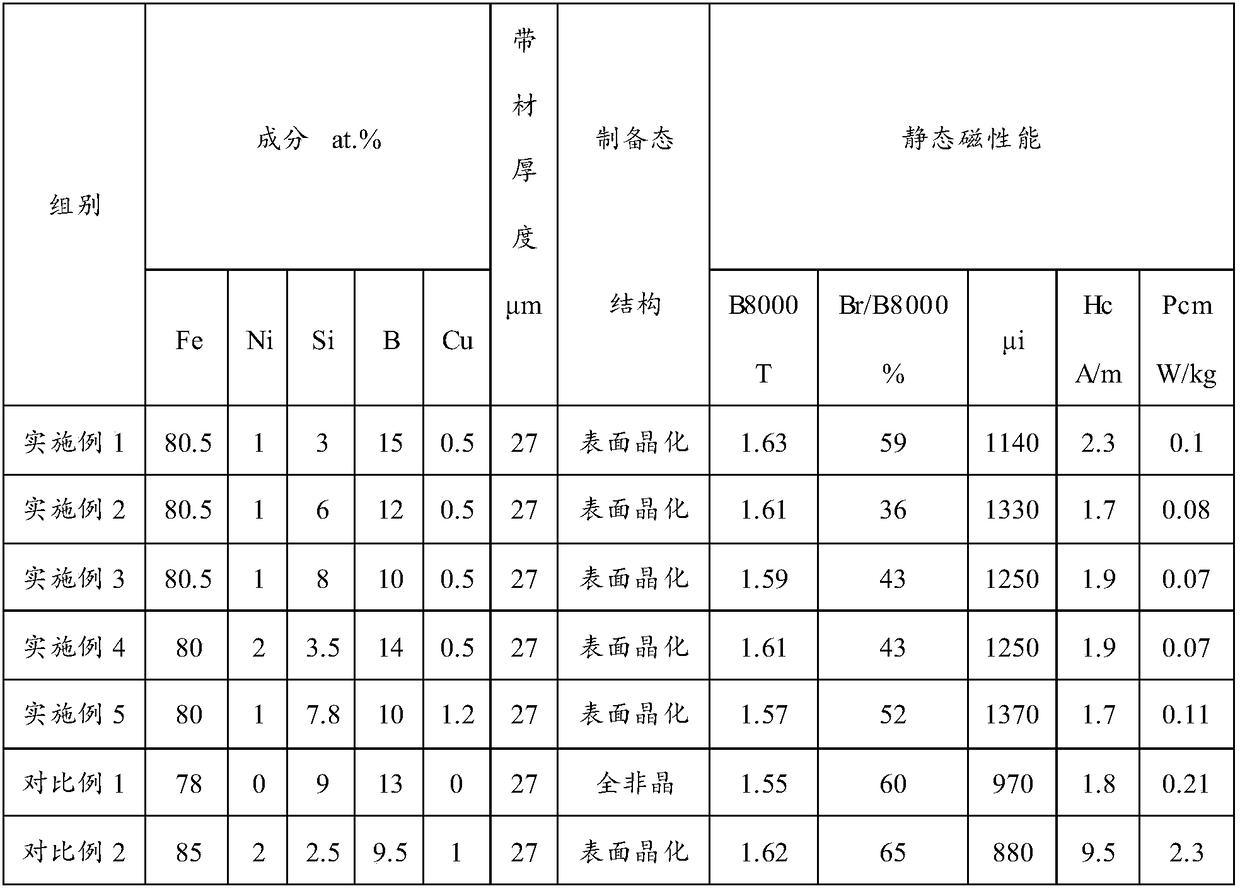

Embodiment 1

[0059] (1) According to the composition formula Fe 100-a-b-c-d Ni a Si b B c Cu d Make ingredients, where a, b, c, and d respectively represent the atomic percentage of the corresponding component: 0.5≤a≤3, 3≤b≤8, 10≤c≤15, 0.3≤d≤2;

[0060] (2) According to the ingredients in the above step (1), the raw materials are smelted into molten steel;

[0061] (3) Adjust the temperature of the molten steel to 150~400℃ above the alloy liquidus temperature, the height of the molten steel is 350mm; set the copper roller linear speed to 25m / s, and the distance between the nozzle and the copper roller to be 300μm. The iron-based amorphous alloy ribbon is prepared by the roller rapid quenching method;

[0062] (4) The iron-based amorphous alloy thin strip obtained in step (3) is wound into a ring-shaped closed magnetic core with an outer diameter of 25mm and an inner diameter of 19.5mm;

[0063] (5) The iron-based amorphous magnetic core prepared in step (4) is subjected to ordinary heat treatment...

Embodiment 2

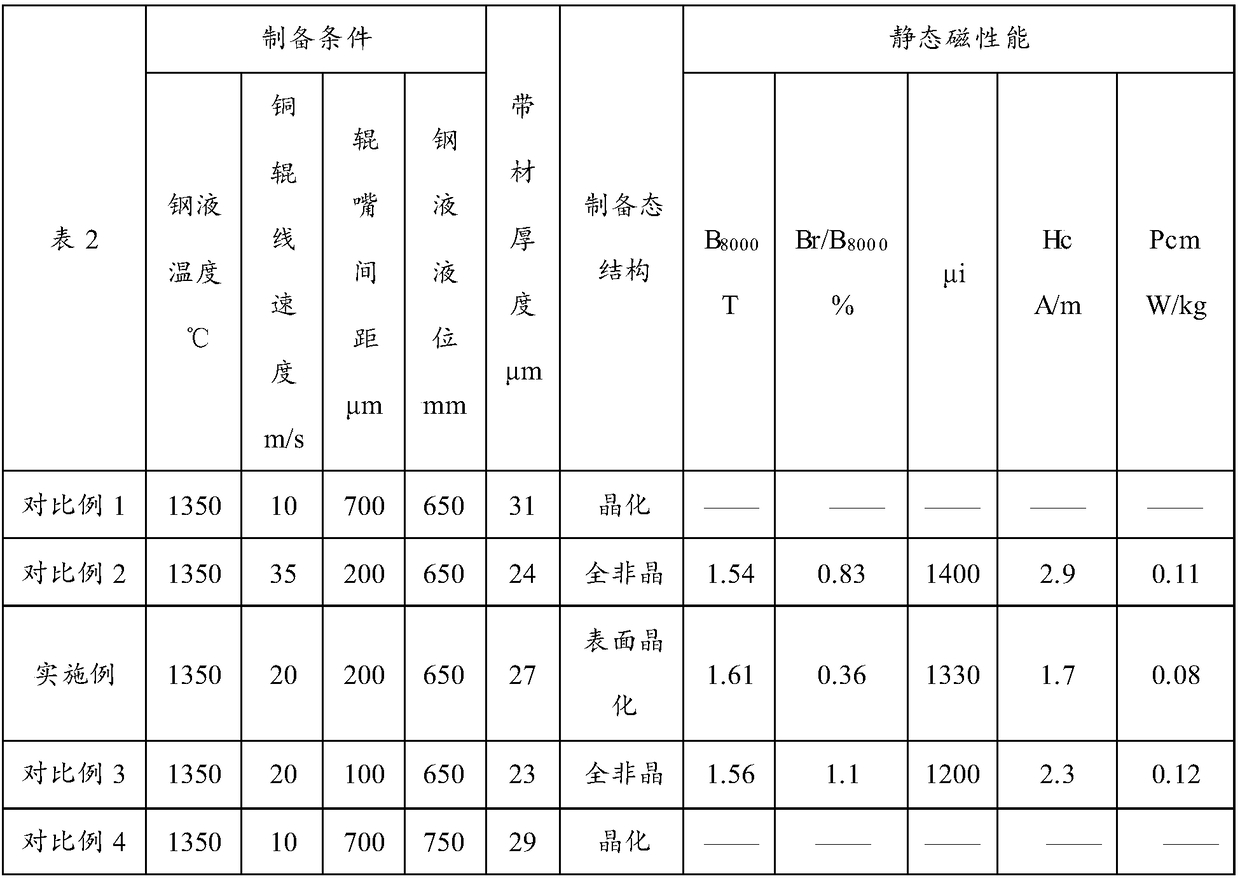

[0069] Using different process conditions to prepare Fe 80.5 Ni 1 Si 6 B 12 Cu 0.5 For amorphous ribbons, the specific steps are as follows:

[0070] (1) Select the component Fe 80.5 Ni 1 Si 6 B 12 Cu 0.5 Make ingredients

[0071] (2) According to the ingredients in the above step (1), the raw materials are smelted into molten steel;

[0072] (3) Adjust the temperature of the molten steel to 1350℃, the height of the molten steel level is 650mm; set the copper roller linear speed to 10~35m / s (specifically 10m / s, 20m / s and 35m / s), the nozzle and copper The distance between the rollers is 100-300μm (specifically 100μm, 200μm and 300μm), the iron-based amorphous alloy ribbon is prepared by a single-roll rapid quenching method, the width of the ribbon is 30mm, and the thickness is 23-31μm;

[0073] (4) The iron-based amorphous alloy thin strip obtained in step (3) is wound into a toroidal closed magnetic core, the outer diameter of the core is 32mm, the inner diameter is 25mm, and the heig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com