A kind of low reflection, high absorption electromagnetic shielding material and preparation method thereof

An electromagnetic shielding material and high-absorption technology, which is applied in the preparation of high-absorption electromagnetic shielding leather and low-reflection fields, can solve the problems of electromagnetic wave secondary pollution and low absorption loss of electromagnetic shielding leather, so as to improve absorption performance and ensure wearability , the effect of enhancing dielectric loss and magnetic loss performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A low reflection, high absorption electromagnetic shielding leather

[0041] The manufacture method of the low-reflection and high-absorption electromagnetic shielding material based on natural leather of the present embodiment is characterized in that it proceeds in the following steps:

[0042] The manufacture method of high absorption electromagnetic shielding material based on natural leather is characterized in that it is carried out according to the following steps and conditions:

[0043] (1) Take a natural leather of a certain size, use vegetable tannin as a carrier, and introduce 20% magnetic nano-ferric oxide particles into the natural leather by the weight of the wet skin;

[0044] (2) Coat the nano-silver-coated copper powder on the surface of the high-absorption leather obtained in (1), and the consumption of the nano-silver-coated copper powder is 6mg cm -2 , that is, low reflection, high absorption electromagnetic shielding leather.

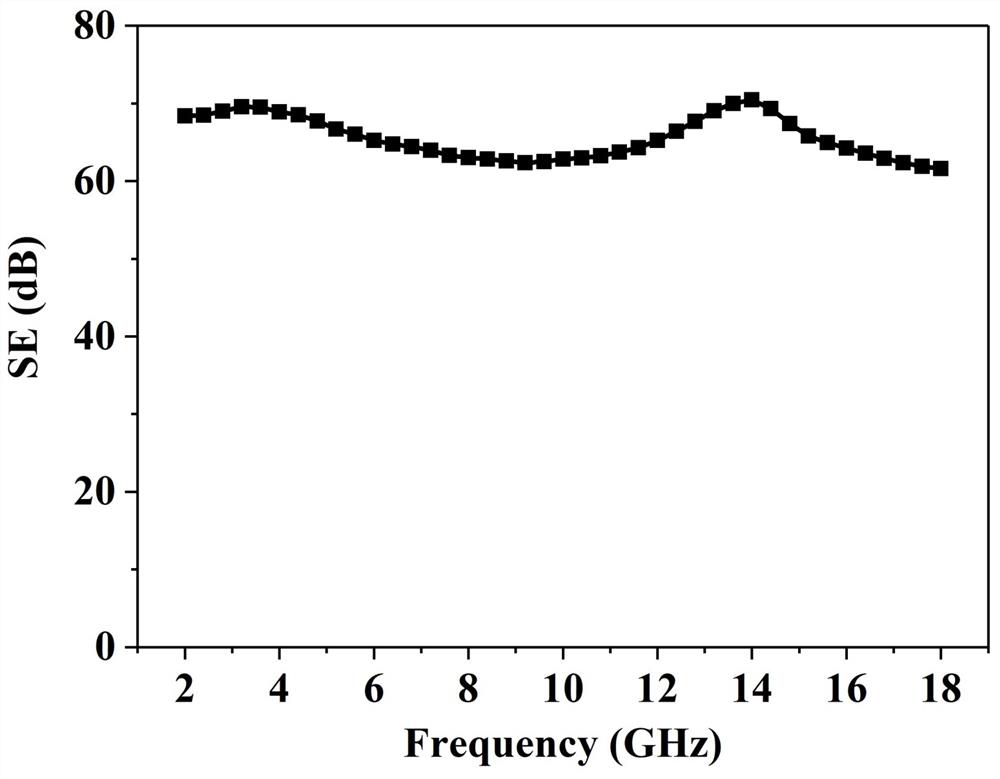

[0045] Such as fi...

Embodiment 2

[0047] A low reflection, high absorption electromagnetic shielding leather

[0048] The manufacture method of the low-reflection and high-absorption electromagnetic shielding material based on natural leather of the present embodiment is characterized in that it proceeds in the following steps:

[0049] (1) Take a natural leather of a certain size, introduce 10% pyrrole monomer based on the weight of wet skin into the natural leather, add the initiator ferric chloride, and polymerize at 0-5°C for 30-60 minutes to form Conductive polypyrrole;

[0051] On the surface of the high absorption leather obtained in (1), the amount of graphene is 2 mg cm -2 , that is, low reflection, high absorption electromagnetic shielding leather.

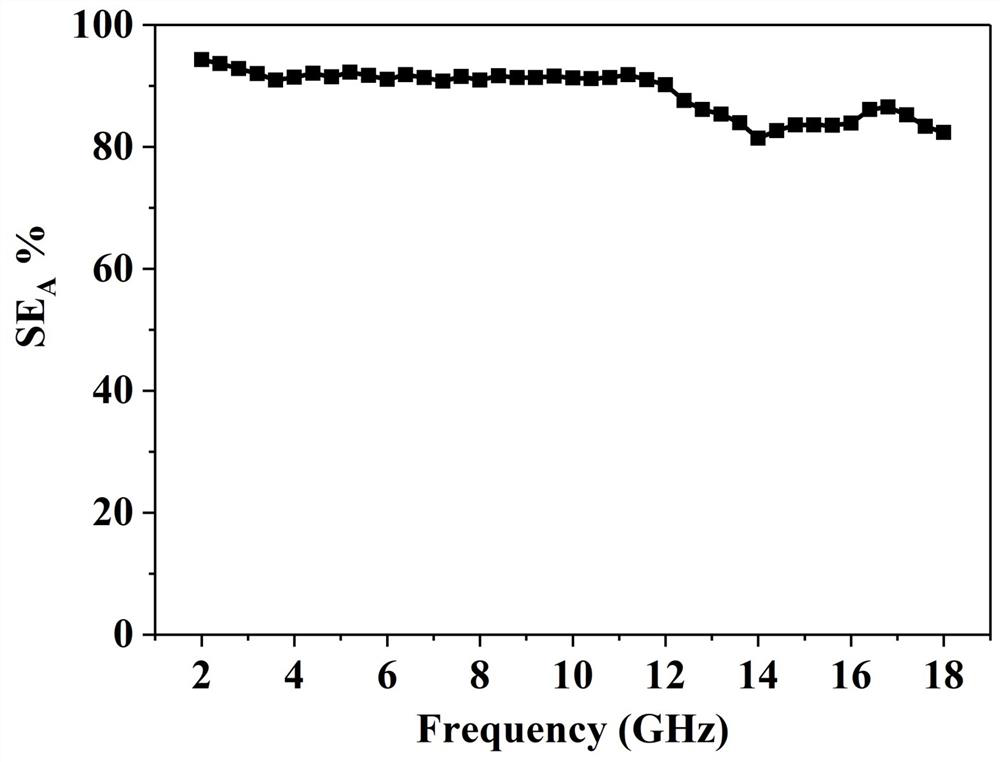

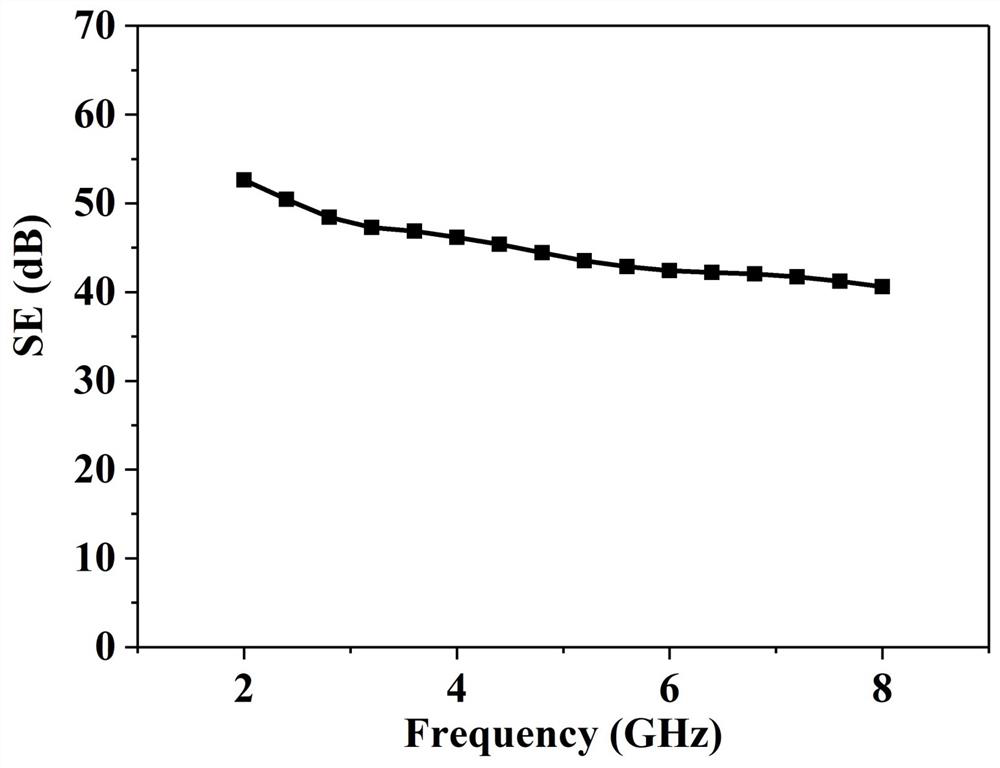

[0052] Such as image 3 and Figure 4 As shown, the surface conductivity of this low reflection, high absorption electromagnetic shielding leather is 8.96×10 2 S / m, the total shielding effectiveness (SE) exceeds 40 dB...

Embodiment 3

[0054] A low reflection, high absorption electromagnetic shielding leather

[0055] The manufacture method of the low-reflection and high-absorption electromagnetic shielding material based on natural leather of the present embodiment is characterized in that it proceeds in the following steps:

[0056] (1) Take a certain size of natural leather, 20% Ag by wet hide weight + After being mixed with vegetable tannins, it is brought into the interior of natural leather through the method of "retanning", and the reduction reaction is carried out at 60-80 ℃ for 60 minutes;

[0057] (2) Coat the silver-coated copper powder on the surface of the high-absorption leather obtained in (1), and the amount of silver-coated copper powder is 4 mg cm -2 , that is, low reflection, high absorption electromagnetic shielding leather.

[0058] Such as Figure 5 and Figure 6 As shown, the surface conductivity of this low reflection, high absorption electromagnetic shielding leather is 4.66×10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com