Preparation method of high-performance viscous elastic sealant

An elastic sealing and viscous technology, applied in the field of building sealants, can solve the problems of poor flame retardancy and application effects, and achieve the effects of good temperature resistance, long service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment relates to a high-performance viscous elastic sealant and a preparation method thereof. The sealant is composed of the following raw materials in parts by weight:

[0048]46 parts of vinyl chloride-acrylate copolymers;

[0049] 30 parts of tert-butylphenol-formaldehyde tackifying resin;

[0050] 8 parts of illite powder with a particle size of 20 μm;

[0051] 3 parts of methylisothiazolinone;

[0052] 7 parts of fluff powder with a particle size of 15 μm;

[0053] 5.5 parts of triphenylmethane triisocyanate;

[0054] 3 parts flaxseed gum;

[0055] 4 parts of tris (butoxyethyl) phosphate;

[0056] Dispersant FT-78 0.8 parts;

[0057] 3 parts of cross-linking agent;

[0058] Accelerator 1 part;

[0059] 1.5 parts of antioxidant;

[0060] 0.4 parts of coupling agent.

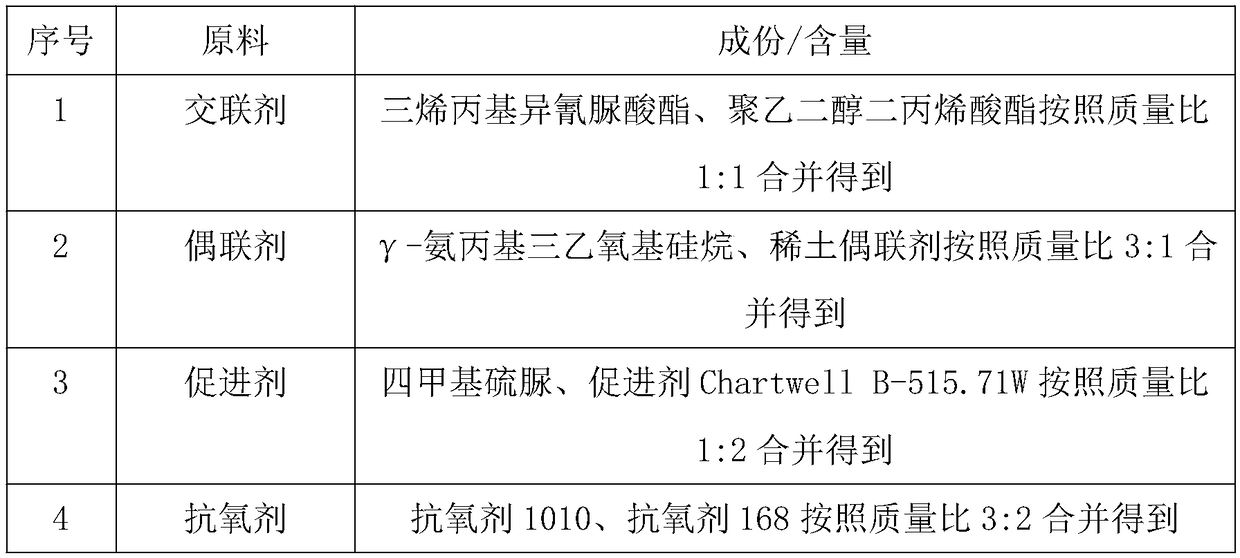

[0061] The selection of crosslinking agent, coupling agent, accelerator and antioxidant in the above raw materials is shown in Table 1 below:

[0062] Table 1

[0063]

[0064]...

Embodiment 2

[0069] This embodiment relates to a high-performance viscous elastic sealant and a preparation method thereof. The sealant is composed of the following raw materials in parts by weight:

[0070] 48 parts of vinyl chloride-acrylate copolymers;

[0071] 34 parts of tert-butylphenolic tackifying resins;

[0072] 10 parts of illite powder with a particle size of 20 μm;

[0073] 3.5 parts of methylisothiazolinone;

[0074] 8 parts of fluff powder with a particle size of 15 μm;

[0075] 6.5 parts of triphenylmethane triisocyanate;

[0076] 3.5 parts of linseed gum;

[0077] 4.5 parts of tris (butoxyethyl) phosphate;

[0078] Dispersant FT-78 0.9 parts;

[0079] 3.5 parts of crosslinking agent;

[0080] Accelerator 1.2 parts;

[0081] 1.8 parts of antioxidant;

[0082] 0.45 parts of coupling agent.

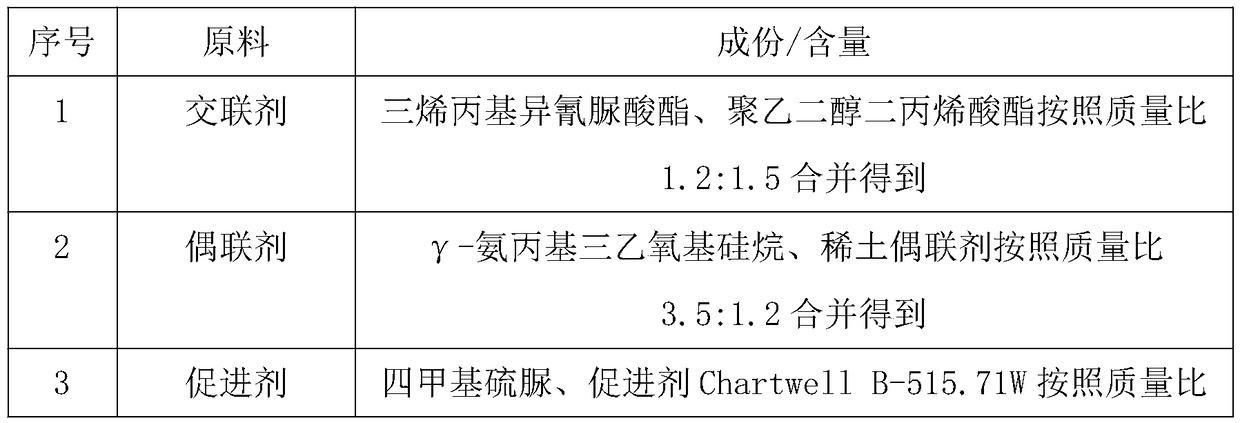

[0083] The selection of crosslinking agent, coupling agent, accelerator and antioxidant in the above raw materials is shown in Table 2 below:

[0084] Table 2

[0085]

[...

Embodiment 3

[0092] This embodiment relates to a high-performance viscous elastic sealant and a preparation method thereof. The sealant is composed of the following raw materials in parts by weight:

[0093] 49 parts of vinyl chloride-acrylate copolymers;

[0094] 35 parts of tert-butylphenol-formaldehyde tackifying resins;

[0095] 11 parts of illite powder with a particle size of 25 μm;

[0096] 4 parts of methylisothiazolinone;

[0097] 9 parts of fluff powder with a particle size of 20 μm;

[0098] 7 parts of triphenylmethane triisocyanate;

[0099] 4 parts flaxseed gum;

[0100] 5 parts of tris (butoxyethyl) phosphate;

[0101] Dispersant FT-78 1 part;

[0102] 4 parts of crosslinking agent;

[0103] Accelerator 1.3 parts;

[0104] Antioxidant 2 parts;

[0105] 0.5 parts of coupling agent.

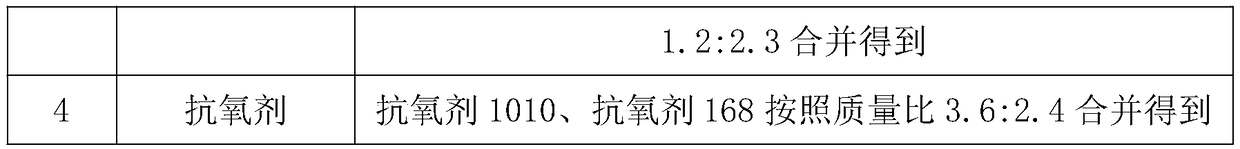

[0106] The selection of crosslinking agent, coupling agent, accelerator and antioxidant in the above raw materials is shown in Table 3 below:

[0107] table 3

[0108]

[0109] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com