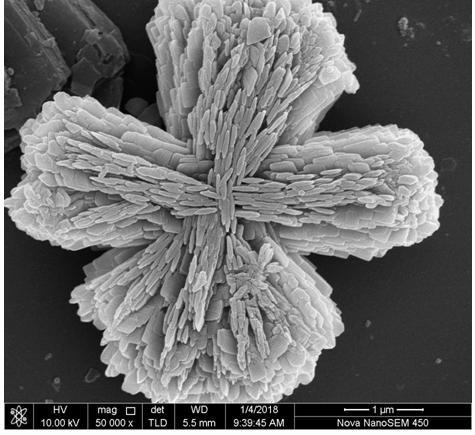

Preparation device and method of bundle-shaped strontium carbonate crystal

A technology of strontium carbonate and crystals, which is applied in the field of preparation of bundled strontium carbonate crystals, can solve problems such as poor greening, complicated operation, and poor controllability, and achieve the effects of low production cost, low price, and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

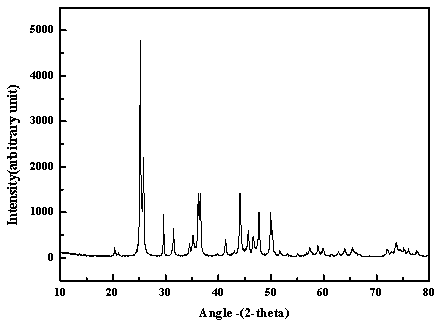

Examples

Embodiment 1

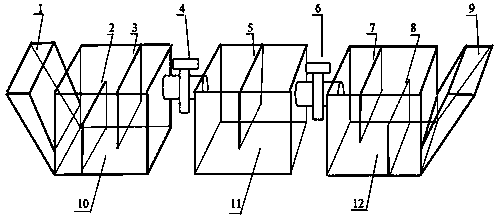

[0016] First, open the No. 1 valve (4) and No. 2 valve (6) in the reaction device, add 0.60 kg of strontium chloride hexahydrate to the No. 1 material tank (10) through the No. Add 0.66 kg of ammonium bicarbonate to the No. 2 material tank (12) from the feed port (9), and add a gelatin solution with a mass fraction of 0.020% in the sedimentation tank to the specified scale; at room temperature, let it stand for 24 hours; feed through No. 1 Add 0.60 kg of strontium chloride hexahydrate to No. 1 material tank (10) through port (1), and add 0.66 kg of ammonium bicarbonate to No. 2 material tank (12) through No. 2 feed port (9); Place the reaction for 24 h, add 0.60 kg strontium chloride hexahydrate to the No. 1 material tank (10) through the No. 1 feed port (1), and add 0.66 kg of ammonium bicarbonate to the No. 2 material tank through the No. 2 feed port (9) Tank (12), at room temperature, stand still for 48 h; close the No. 1 valve (4) and No. 2 valve (6), filter the product in...

Embodiment 2

[0019]First, open the No. 1 valve (4) and No. 2 valve (6) in the reaction device, add 0.60 kg of strontium chloride hexahydrate to the No. 1 material tank (10) through the No. Add 0.64 kg of ammonium bicarbonate to the No. 2 material tank (12) from the feed port (9), and add a gelatin solution with a mass fraction of 0.020% in the sedimentation tank to the specified scale; at room temperature, let it stand for 24 hours; feed through No. 1 Add 0.60 kg of strontium chloride hexahydrate to No. 1 material tank (10) through port (1), and add 0.64 kg of ammonium bicarbonate to No. 2 material tank (12) through No. 2 feed port (9); React for 24 h, add 0.60 kg of strontium chloride hexahydrate to the No. 1 material tank (10) through the No. 1 feed port (1), and add 0.64 kg of ammonium bicarbonate to the No. 2 material tank through the No. 2 feed port (9) Tank (12), at room temperature, stand still for 48 h; close the No. 1 valve (4) and No. 2 valve (6), filter the product in the sedime...

Embodiment 3

[0022] First, open the No. 1 valve (4) and No. 2 valve (6) in the reaction device, add 0.60 kg of strontium chloride hexahydrate to the No. 1 material tank (10) through the No. Add 0.68 kg of ammonium bicarbonate to the No. 2 material tank (12) from the material port (9), and add a gelatin solution with a mass fraction of 0.020% to the specified scale in the sedimentation tank; at room temperature, let it stand for 24 hours; feed through No. 1 Add 0.60 kg of strontium chloride hexahydrate to No. 1 material tank (10) through port (1), and add 0.68 kg of ammonium bicarbonate to No. 2 material tank (12) through No. 2 feed port (9); React for 24 h; add 0.60 kg of strontium chloride hexahydrate to the No. 1 material tank (10) through the No. 1 feed port (1), and add 0.68 kg of ammonium bicarbonate to the No. 2 material tank through the No. 2 feed port (9) Tank (12), at room temperature, stand still for 48 h; close the No. 1 valve (4) and No. 2 valve (6), filter the product in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com