Adjustable cutting device for paper packages and using method of adjustable cutting device

A cutting device and packaging technology, applied in the direction of packaging, transportation and packaging, papermaking, etc., can solve the problems of damage and loss of packaging paper, and achieve the effects of solving paper damage, accurate positioning, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

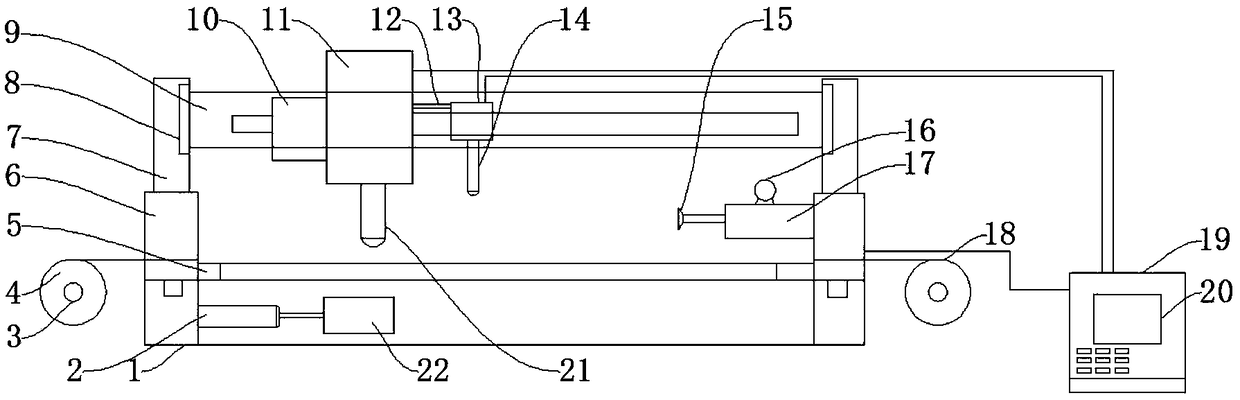

[0024] like Figure 1-Figure 4 As shown, an adjustable cutting device for paper packaging includes a frame main body 1, an unwinding drive motor 2, a paper unwinding roller 4, a telescopic hydraulic rod 7, and a generator drive motor 10. The unwinding drive motor 2 is arranged between, and a motor reduction box 22 is installed on one side of the unwinding drive motor 2, and the motor reduction box 22 controls the working speed of the unwinding drive motor 2, and the frame main body 1 One side is provided with a roller fixing frame 3, the paper unwinding roller 4 is arranged on the outside of the roller fixing frame 3, and a paper conveyor belt 5 is arranged above the frame main body 1, and the paper conveyor belt 5 transports the paper, so A push hydraulic cylinder 6 is installed above the paper conveyor belt 5, and the telescopic hydraulic rod 7 is installed above the push hydraulic cylinder 6. A slider 8 is installed inside the telescopic hydraulic rod 7, and a moving slider...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is:

[0027] In this embodiment, the water storage box 17 is fixed between the frame main body 1 by bolts, the centrifugal booster pump 16 and the water storage box 17 are connected by pipelines, and the water storage box 17 is connected with the high-pressure water nozzle 15 through pipelines.

[0028] Specifically, such an arrangement can extinguish the paper when the paper catches fire, preventing the flame from damaging the device.

[0029] The present invention also provides a method for using an adjustable cutting device for paper packaging, which is applied to the above-mentioned adjustable cutting device for paper packaging. The paper is placed above the paper unwinding roller 4, and the unwinding drive motor 2 Drive the paper unwinding roller 4 to work, convey the paper to the top of the paper conveyor belt 5, adjust the pushing hydraulic cylinder 6 according to the thickness of the paper, so that the tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com