Surface acoustic wave-based atomization device and method

A technology of surface acoustic wave and atomization device, which is applied in the direction of nebulizer for treatment, etc., can solve the problems of large diameter range of aerosol particles, inconvenient to carry or transport, and evaporation of liquid to be atomized. The effect of liquid evaporation and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] refer to figure 1 , an atomization device based on surface acoustic waves provided in Embodiment 1 of the present invention, including: atomization chip 1, polyester fiber paper 2 and liquid storage tank 4;

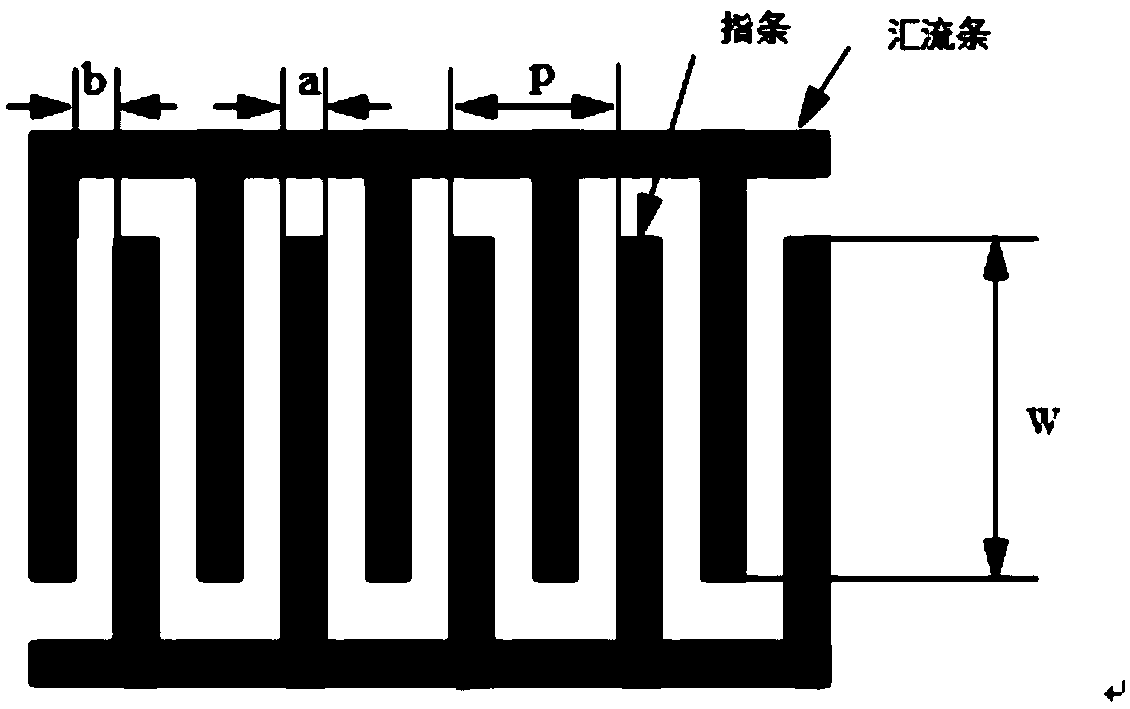

[0041] The atomization chip 1 includes a piezoelectric single crystal substrate 101 and an interdigital transducer 103 arranged on the piezoelectric single crystal substrate 101;

[0042] One end of the polyester fiber paper 2 is attached to the upper surface of the piezoelectric single crystal substrate 101, the other end is inserted into the liquid storage tank 4, and the liquid in the liquid storage tank 4 is sucked into the piezoelectric single crystal. The upper surface of the substrate 101;

[0043] The interdigital transducer 103 is driven by a radio frequency signal to generate a surface acoustic wave on the upper surface of the piezoelectric single crystal substrate 101 to atomize the liquid on the upper surface of the piezoelectric single crystal substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com