Cocoa flavor, cake flavor and walnut flavor

A technology of cocoa essence and essence, which is applied in the direction of food ingredients as odor improvers, acid-containing food ingredients, food adsorption, etc., can solve the problems of long production cycle, large investment in equipment, low yield, etc., and achieve a breakthrough in the insufficient strength of essence Bottleneck, promotes the production of aroma substances, high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of cocoa essence

[0018] A. Thermal reaction: Add 50g of cocoa powder to the thermal reaction container, add 30g of leucine, 30g of glutamic acid, 10g of phenylalanine, 20g of arginine, 20g of alanine, 5g of glycine, 10g of serine, 130g of fructose, Water 5000g, citric acid to adjust the pH to 6.5, 95°C sealed reaction for 10h;

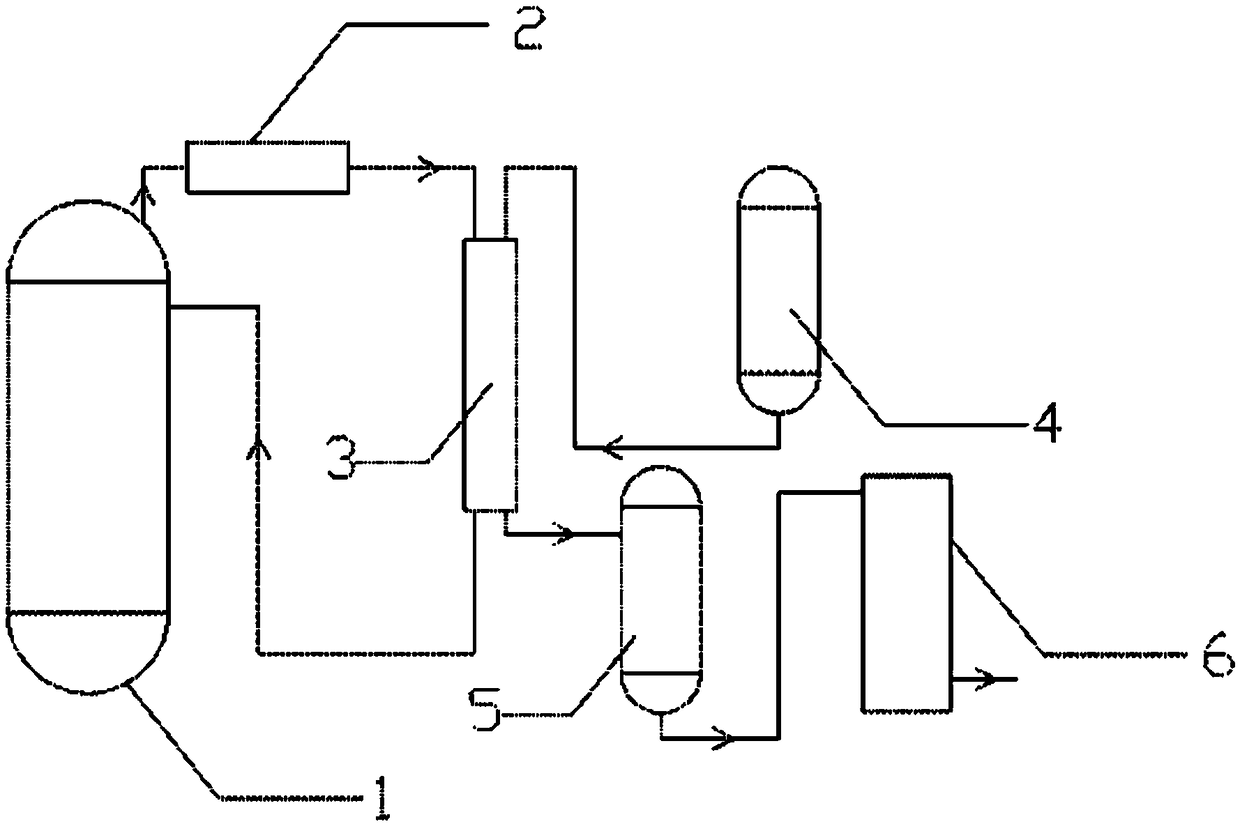

[0019] B. Simultaneous reaction and adsorption: connect the thermal reaction vessel, condensation device and chromatography device to form a loop; add macroporous resin to the chromatography device; continue to heat the thermal reaction solution to boiling, and the steam produced by boiling The condensed device is condensed into condensate and enters the chromatographic device. The aroma substances in the condensate are absorbed by the macroporous resin, and the liquid without aroma components is finally returned to the thermal reaction vessel, forming a cycle and maintaining it for 3 hours;

[0020] C. Desorptio...

Embodiment 2

[0022] Embodiment 2: the preparation of cake essence

[0023] A. Thermal reaction: add egg yolk powder 40g, whole milk powder 3g, arginine 20g, alanine 15g, serine 20g, leucine 2g, isoleucine 6g, phenylalanine 0.1g, Lactose 10g, glucose 30g, anhydrous butter 3g, water 5000g, citric acid to adjust the pH to 7.5, 105°C sealed reaction for 3h;

[0024] B. Simultaneous reaction and adsorption: connect the thermal reaction vessel, condensation device and chromatography device to form a loop; add silica gel to the chromatography device; continue heating the thermal reaction solution to boiling, and the steam generated by boiling is condensed The device is condensed into a condensate and enters the chromatography device. The aroma substances in the condensate are absorbed by silica gel, and the liquid without aroma components is finally returned to the hot reaction vessel, forming a cycle and maintaining it for 1h;

[0025] C. Desorption to prepare essence: After the adsorption proc...

Embodiment 3

[0027] Embodiment 3: the preparation of walnut essence

[0028] A. Thermal reaction: Add 100g of soybean protein enzymatic hydrolysis solution, 40g of arginine, 15g of histidine, 20g of glutamic acid, 15g of glycolic acid, 18g of aspartic acid, 1g of leucine, and phenylpropanoid into the thermal reaction container. Amino acid 2g, alanine 15g, cystine 0.5g, methionine 0.05g, walnut oil 4g, xylose 100g, water 4000g, stir evenly, citric acid adjust pH to 6.5, 100h airtight reaction 8h;

[0029] B. Simultaneous reaction and adsorption: Connect the thermal reaction vessel, condensation device and chromatography device to form a loop; add activated carbon to the chromatography device; continue heating the thermal reaction solution to boiling, and the steam generated by boiling is condensed The device is condensed into a condensate and enters the chromatography device. The aroma substances in the condensate are absorbed by activated carbon, and the liquid without aroma components is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com