A method for coproduction of additive-free sugarcane molasses and additive-free granulated sugar

A cane molasses, zero-addition technology, used in the production of cane sugar, sugar production, purification using physical methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

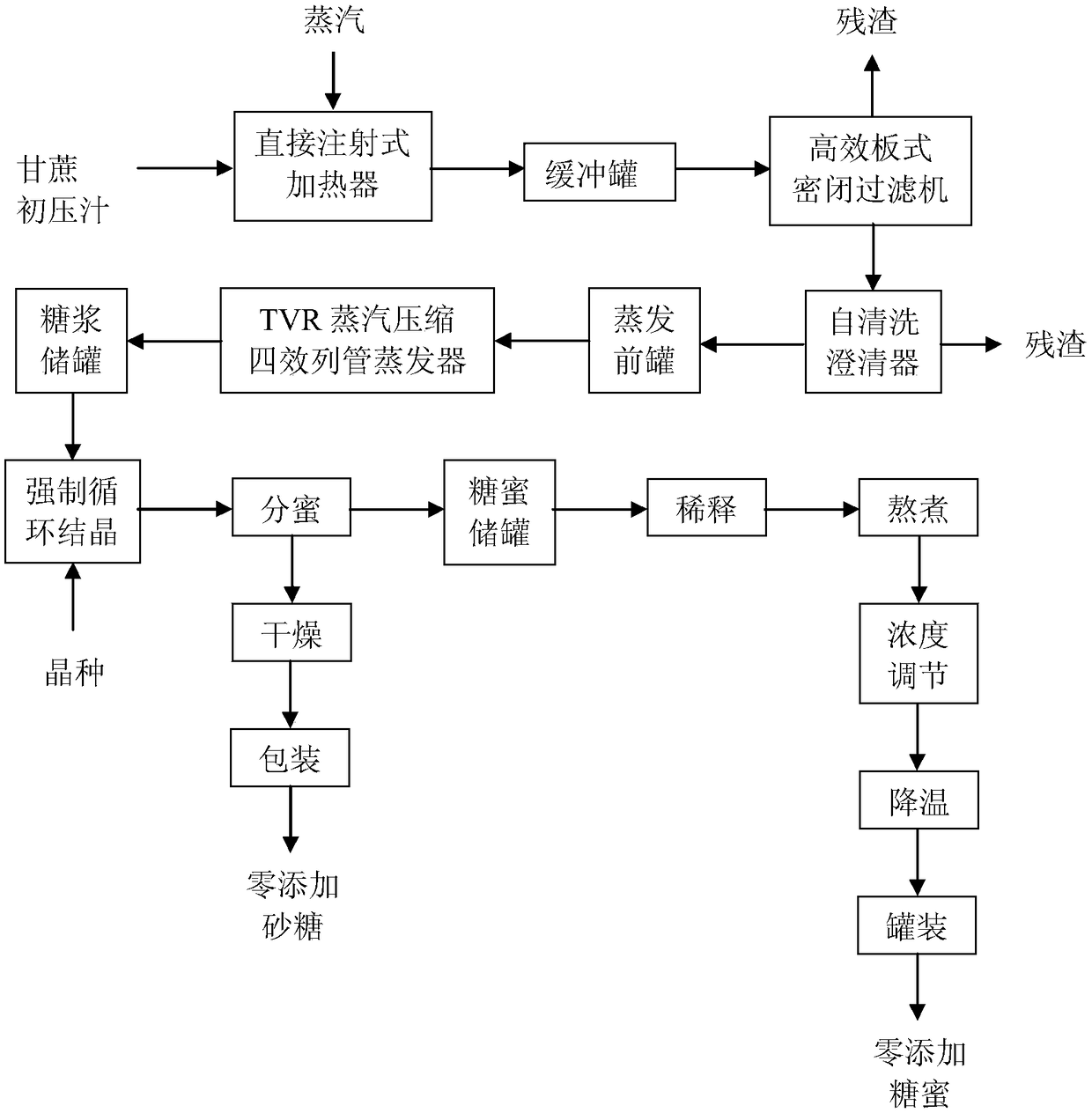

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Press 5m 3 The flow rate of / h uses a centrifugal pump to extract the sugarcane initial pressure juice to the buffer tank, and installs a direct injection heater (also called a water heater, injector) on the pipeline between the centrifugal pump and the buffer tank, and the feed liquid inlet of the heater Connect sugarcane initial pressure juice, steam inlet to 0.3MPa saturated steam pipe, feed liquid outlet to the pipeline to the buffer tank, adjust the steam flow rate so that the outlet feed liquid temperature reaches 95°C±1°C, the purpose of heating the initial pressure juice It is to denature the colloid in it, which is beneficial to filter and remove. The heated sugarcane juice is then centrifugally pumped to the NYB series high-efficiency plate-type airtight filter to filter and remove the colloid and other impurities in the initial pressure juice. There are 2 filters, one for use and one for standby. When the filter pressure reaches 0.4MPa, switch to ...

Embodiment 2

[0015] Example 2: According to 10m 3 The flow rate of / h uses a centrifugal pump to extract the sugarcane initial pressure juice to the buffer tank, and installs a direct injection heater (also called a water heater, injector) on the pipeline between the centrifugal pump and the buffer tank, and the feed liquid inlet of the heater Connect sugarcane initial pressure juice, steam inlet to 0.5MPa saturated steam pipeline, feed liquid outlet to the pipeline to the buffer tank, adjust the steam flow to make the outlet feed liquid temperature reach 90°C±1°C, and heat the initial pressure juice It is to denature the colloid in it, which is beneficial to filter and remove. The heated sugarcane juice is then centrifugally pumped to the NYB series high-efficiency plate-type airtight filter to filter and remove the colloid and other impurities in the initial pressure juice. There are 2 filters, one for use and one for standby. When the filter pressure reaches 0.4MPa, switch to Another f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com