A kind of preparation method and device of tungsten pentachloride

A technology of tungsten pentachloride and tungsten tetrachloride, applied in tungsten halide and other directions, can solve problems such as inability to transport, achieve simple daily operation and maintenance, facilitate automatic control, and ensure the effect of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

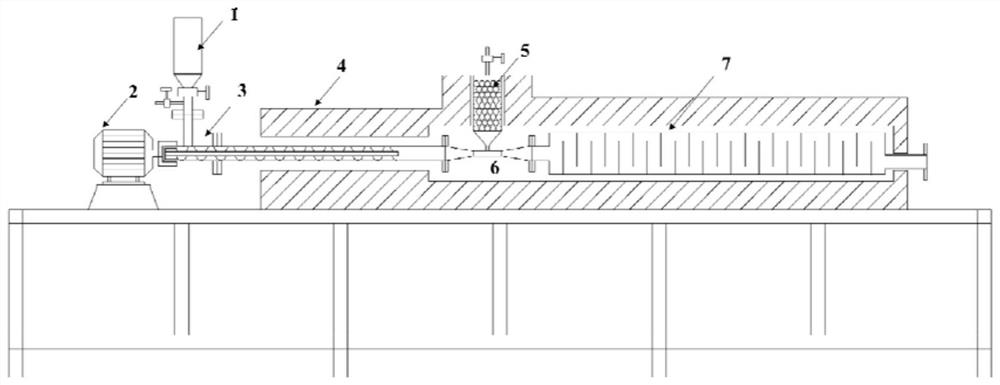

[0026] see figure 1 , put 5kg of tungsten tetrachloride into the raw material container 1, the raw material container 1 is connected with the vacuum transition chamber, repeat vacuuming and flushing with nitrogen three times, then open the discharge valve, and open the inert carrier gas at 3L / min at the same time, so that the tungsten tetrachloride The particles fall into the screw feeder 3 under the dual action of gravity and air flow, and are pushed to the heating and sublimation zone by the screw. The heating and sublimation temperature of the material is 450°C, and the obtained tungsten tetrachloride vapor is transported into the mixer 6. Adjust the intake flow rate of chlorine gas to 1.3L / min through the intake valve, so that the preheated chlorine gas and tungsten tetrachloride vapor are fully mixed in the Venturi tube. The mixed gas fully reacts in the labyrinth tube reactor 7, the reaction temperature is 300°C, and the generated steam is collected through condensation....

Embodiment 2

[0030] see figure 1 , put 10kg of tungsten dichloride and tungsten tetrachloride mixture into the raw material container, the raw material container 1 is connected to the vacuum transition chamber, repeat vacuuming and flushing with nitrogen three times, then open the discharge valve, and open the inert carrier gas at 5L / min at the same time, The tungsten tetrachloride particles fall into the screw feeder 3 under the double action of gravity and air flow, and are pushed to the heating and sublimation zone by the screw. Adjust the intake flow rate of chlorine gas to 3L / min through the intake valve, so that the preheated chlorine gas and tungsten tetrachloride vapor are fully mixed in the Venturi tube. The mixed gas fully reacts in the labyrinth tube reactor 7, the reaction temperature is controlled at 500°C, and the generated steam is collected through condensation. Table 2 is the chemical analysis results of the product.

[0031] Table 2 implementation case 2 gained tungsten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com