Extraction and purification method of total alkaloids of Sophora sophora

A purification method, the technology of Sophora sophora, which is applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of organic solvent residues, unfavorable clean production, low extraction rate, etc., and reach the production cycle Short, fast adsorption speed, large adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

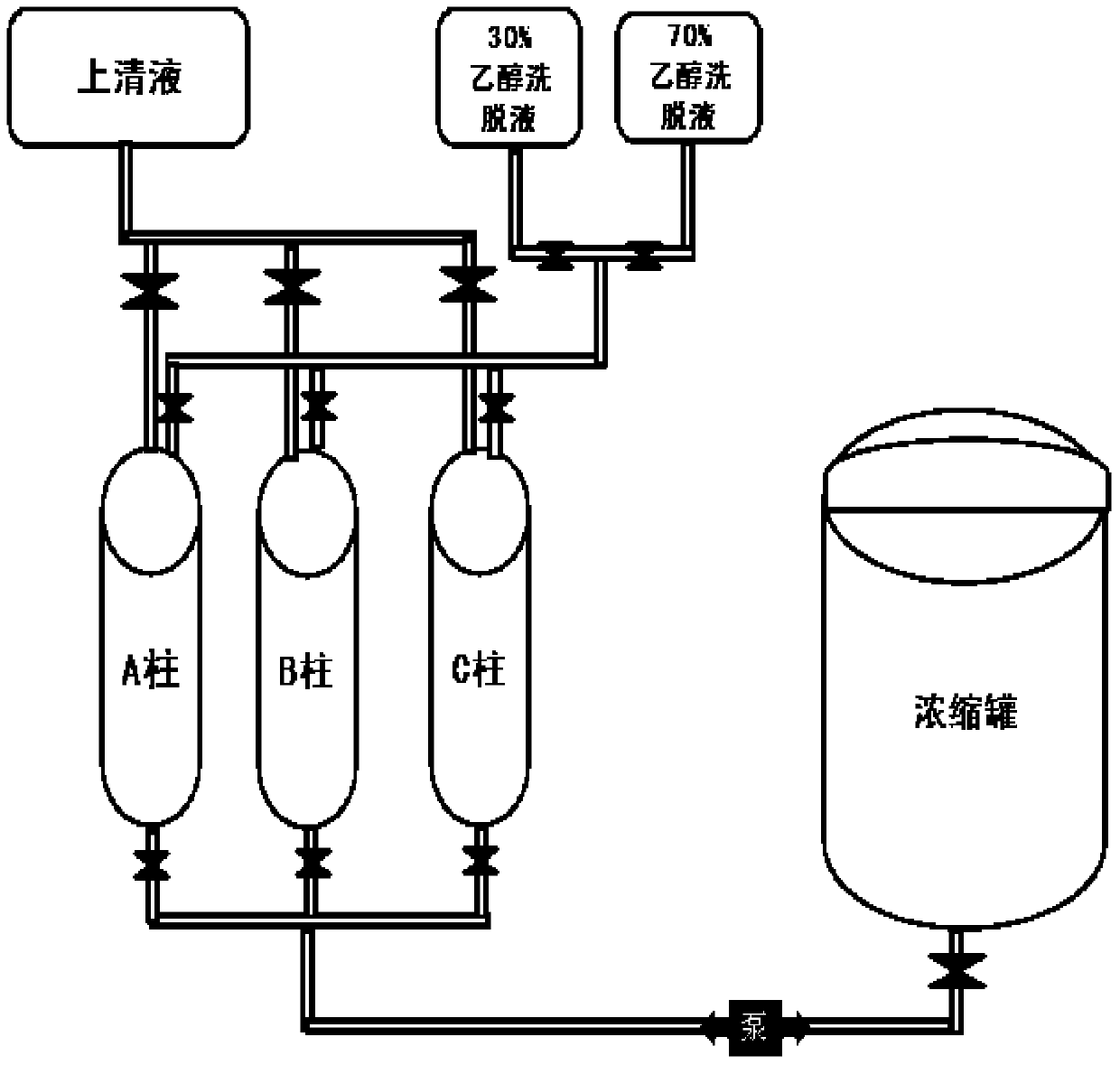

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Take 100kg of Sophora sophora as an example.

[0023] 1. Cutting

[0024] Cut the weighed Alopecia sophora into small pieces of 1-2 cm, and set aside.

[0025] 2. Cellulase enzymatic hydrolysis

[0026] Put the sliced Alopecia sophora into a multi-functional extraction tank (note that the feeding should be even and tight, so as to facilitate the cooking and extraction in the subsequent process), add water (the ratio of material to liquid is 1:8), adjust the pH to 5 with hydrochloric acid, and add its weight 0.1% cellulase, and incubated at 50°C for 4h.

[0027] 3. Extract after decoction and extraction

[0028] Cover the multi-functional extraction tank containing the material after enzymatic hydrolysis, add hydrochloric acid until the pH value of the liquid is 3, heat to a slight boil on the liquid surface, discharge the material after 2 hours, put the filtrate into the liquid storage tank, and then extract Add dilute hydrochloric acid solution (pH ...

Embodiment 2

[0042] Embodiment 2: Take 100kg of Sophora sophora as an example.

[0043] 1. Cutting

[0044] Cut the weighed Alopecia sophora into small pieces of 1-2 cm, and set aside.

[0045] 2. Cellulase enzymatic hydrolysis

[0046] Put the sliced Alopecia sophora into a multi-functional extraction tank (note that the feeding should be tight and even, so as to facilitate the cooking and extraction in the subsequent process), add water (the ratio of material to liquid is 1:10), adjust the pH to 4 with hydrochloric acid, and add its weight 0.2% cellulase, and incubated at 35°C for 4h.

[0047] 3. Extract after decoction and extraction

[0048] Cover the multi-functional extraction tank containing the material after enzymatic hydrolysis, add hydrochloric acid until the pH value of the liquid is 2, heat until the liquid surface boils slightly, discharge the material after 2 hours, put the filtrate into the liquid storage tank, and then extract Add dilute hydrochloric acid solution (p...

Embodiment 3

[0062] Embodiment 3: Take 200kg of Sophora Sophorae as an example.

[0063] 1. Cutting

[0064] Cut the weighed Alopecia sophora into small pieces of 1-2 cm, and set aside.

[0065] 2. Cellulase enzymatic hydrolysis

[0066] Put the sliced Alopecia sophora into a multi-functional extraction tank (note that the feeding should be tight and even, so as to facilitate the cooking and extraction in the subsequent process), add water (the ratio of material to liquid is 1:9), adjust the pH to 6 with hydrochloric acid, and add its weight 0.3% cellulase, and incubated at 65°C for 6h.

[0067] 3. Extract after decoction and extraction

[0068] Cover the multi-functional extraction tank containing the material after enzymatic hydrolysis, add hydrochloric acid until the pH value of the liquid is 4, heat to a slight boil on the liquid surface, discharge the material after 2 hours, put the filtrate into the liquid storage tank, and then extract Add dilute hydrochloric acid solution (pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com