A slow-release glass fertilizer and its industrial production method

A production method and glass technology, applied in the direction of inorganic fertilizers, cyanamide fertilizers, fertilizer mixtures, etc., can solve the problems of less than 1%, no large-scale application, and inability to achieve continuous production, and achieve the effect of prolonging fertilizer efficiency and solving time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Its preparation method comprises the following steps:

[0042] 1) After the calcium carbide and fluorite are crushed in the jaw crusher respectively, they are ground into a powder with a particle size of less than 2mm by the crusher;

[0043] 2) Use a glass pulverizer to pulverize the waste glass or quartz sand into a powder with a particle size of less than 2mm;

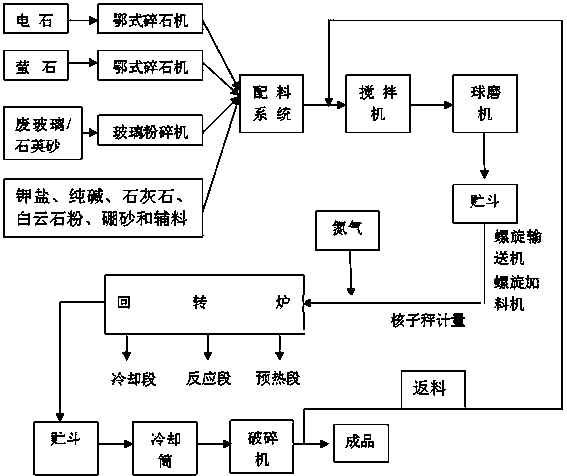

[0044] 3) Proportion the obtained calcium carbide powder, fluorite powder, waste glass or quartz sand powder with potassium salt, soda ash, limestone, dolomite powder, borax and auxiliary materials through the batching system, and then send them into the mixer through the elevator to fully mix; The mixed coarse furnace charge is transported to the ball mill through the conveyor belt, ground into a powder charge with a fineness of less than 100 mesh, and then sent to the storage hopper through the elevator; After weighing and controlling the speed of the scale, spray nitrogen into the rotary furnace, preheat ...

Embodiment 1

[0047] A slow-release glass fertilizer, its raw material ratio is: waste glass 30%, calcium carbide 60%, fluorite 3%, auxiliary materials 7%; wherein, the auxiliary materials used are zinc sulfate, copper sulfate, manganese dioxide, ammonium molybdate and A mixture of iron oxides in a weight ratio of 3:2:2:2:1.

[0048] During the preparation process of the slow-release glass fertilizer, the reaction conditions in the rotary kiln are: 800° C., nitrogen pressure 0.6 kPa, and the rest of the preparation steps are carried out as above.

Embodiment 2

[0050] A slow-release glass fertilizer, its raw material ratio is: quartz sand 50%, calcium carbide 40%, fluorite 1%, soda ash 3%, limestone 3%, dolomite powder 3%.

[0051] During the preparation process of the slow-release glass fertilizer, the reaction conditions in the rotary kiln are: 1100° C., nitrogen pressure 0.8 kPa, and the rest of the preparation steps are carried out as above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com