System and method of coproduction of propylene oxide and arene

A technology for the reaction of propylene oxide and aromatic hydrocarbons, applied in the field of chemical process, can solve the problems of large amount of solvent recovery, difficult environmental treatment of waste residue and waste gas, and high investment in solvent recovery equipment, and achieves the effect of reducing steam consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

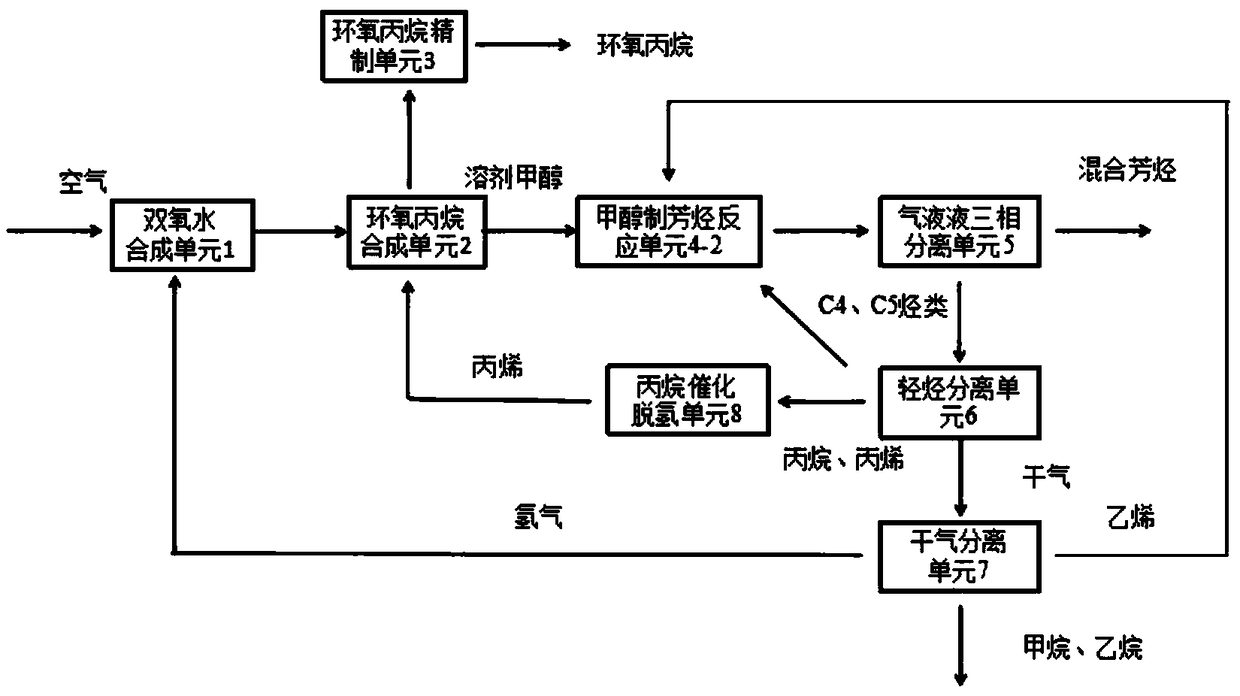

[0025] Embodiment 1, with reference to figure 2 , a system for the co-production of hydrocarbons from propylene oxide, comprising a hydrogen peroxide synthesis unit 1, the output of the hydrogen peroxide synthesis unit 1 is connected to the first input of the propylene oxide synthesis unit 2, the second input of the propylene oxide synthesis unit 2 and propylene Pipeline connection, propylene oxide output of propylene oxide synthesis unit 2 and input connection of propylene oxide refining unit 3, solvent methanol output of propylene oxide synthesis unit 2 and first input connection of methanol-to-aromatics reaction unit 4-2, The output of the methanol-to-aromatics reaction unit 4-2 is connected to the input of the gas-liquid-liquid three-phase separation unit 5, the first output of the gas-liquid-liquid three-phase separation unit 5 is connected to the input of the light hydrocarbon separation unit 6, and the light hydrocarbon separation unit 6 The output of C3, C4, C5 hydroc...

Embodiment 2

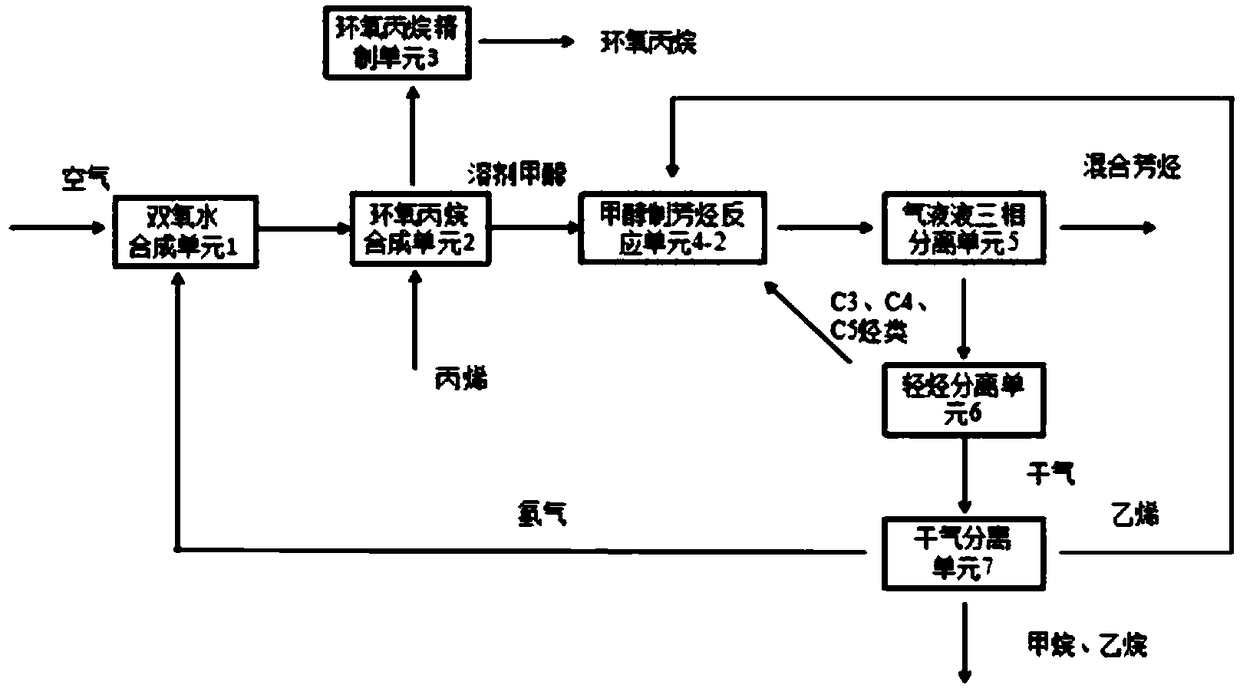

[0030] Embodiment 2, with reference to image 3 , a system for the co-production of hydrocarbons from propylene oxide, comprising a hydrogen peroxide synthesis unit 1, the output of the hydrogen peroxide synthesis unit 1 is connected to the first input of the propylene oxide synthesis unit 2, the propylene oxide output of the propylene oxide synthesis unit 2 and The input connection of propylene oxide refining unit 3, the solvent methanol output of propylene oxide synthesis unit 2 and the first input connection of methanol to aromatics reaction unit 4-2, the output of methanol to aromatics reaction unit 4-2 and gas-liquid-liquid three-phase The input connection of the separation unit 5, the first output of the gas-liquid-liquid three-phase separation unit 5 and the input connection of the light hydrocarbon separation unit 6, the C4 and C5 hydrocarbon output of the light hydrocarbon separation unit 6 and the reaction unit 4-2 of methanol to aromatics The second input connection...

Embodiment 3

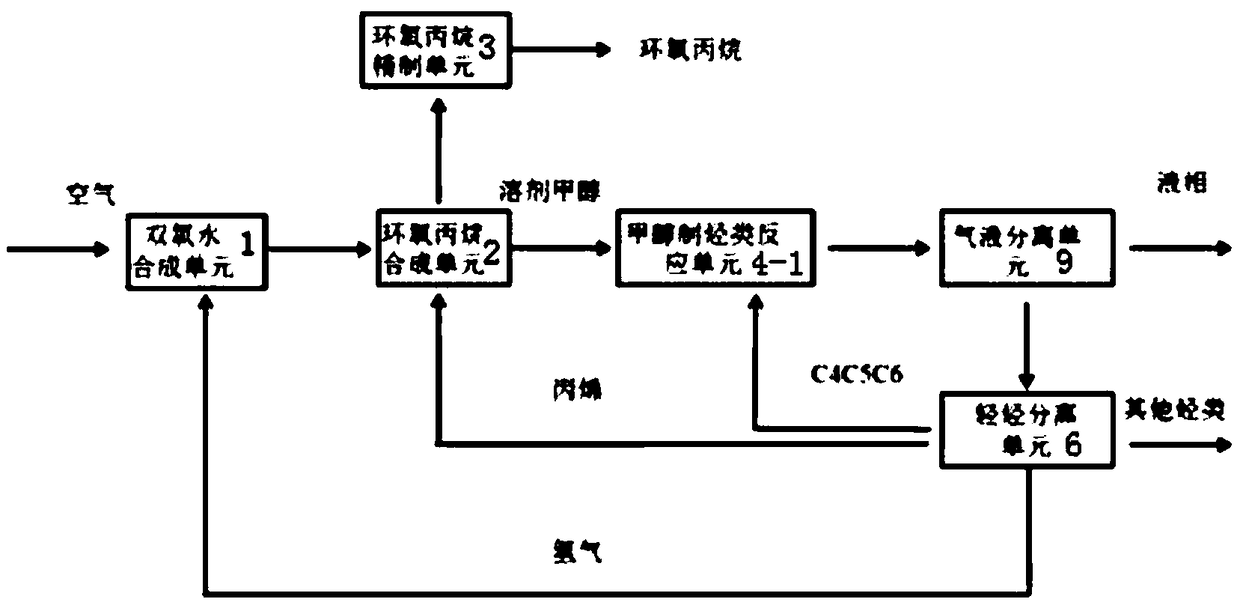

[0034] Embodiment 3, with reference to Figure 4 , a system for the co-production of hydrocarbons from propylene oxide, comprising a hydrogen peroxide synthesis unit 1, the output of the hydrogen peroxide synthesis unit 1 is connected to the first input of the propylene oxide synthesis unit 2, the propylene oxide output of the propylene oxide synthesis unit 2 and The input connection of propylene oxide refining unit 3, the solvent methanol output of propylene oxide synthesis unit 2 and the first input connection of methanol to olefins reaction unit 4-3, the output of methanol to olefins reaction unit 4-3 and gas-liquid-liquid three-phase The input connection of the separation unit 5, the first output of the gas-liquid-liquid three-phase separation unit 5 and the input connection of the light hydrocarbon separation unit 6, the C4 and C5 hydrocarbon output of the light hydrocarbon separation unit 6 and the methanol-to-olefins reaction unit 4-3 The second input connection of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com