Lithium titanate material and preparation method thereof

A lithium titanate, the technology of lithium titanate, applied in the directions of titanate, alkali metal titanate, chemical instruments and methods, etc., can solve the problems of poor electronic conductivity and rate performance, so as to improve the electronic conductivity, The effect of improving rate capability and electrochemical kinetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

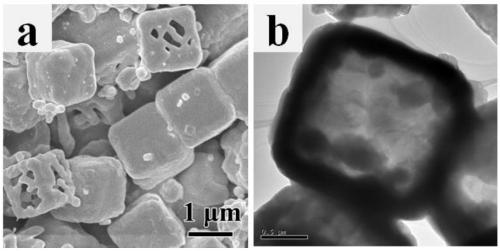

[0041] The preparation method of the hollow cubic lithium titanate material provided in this embodiment includes the following steps:

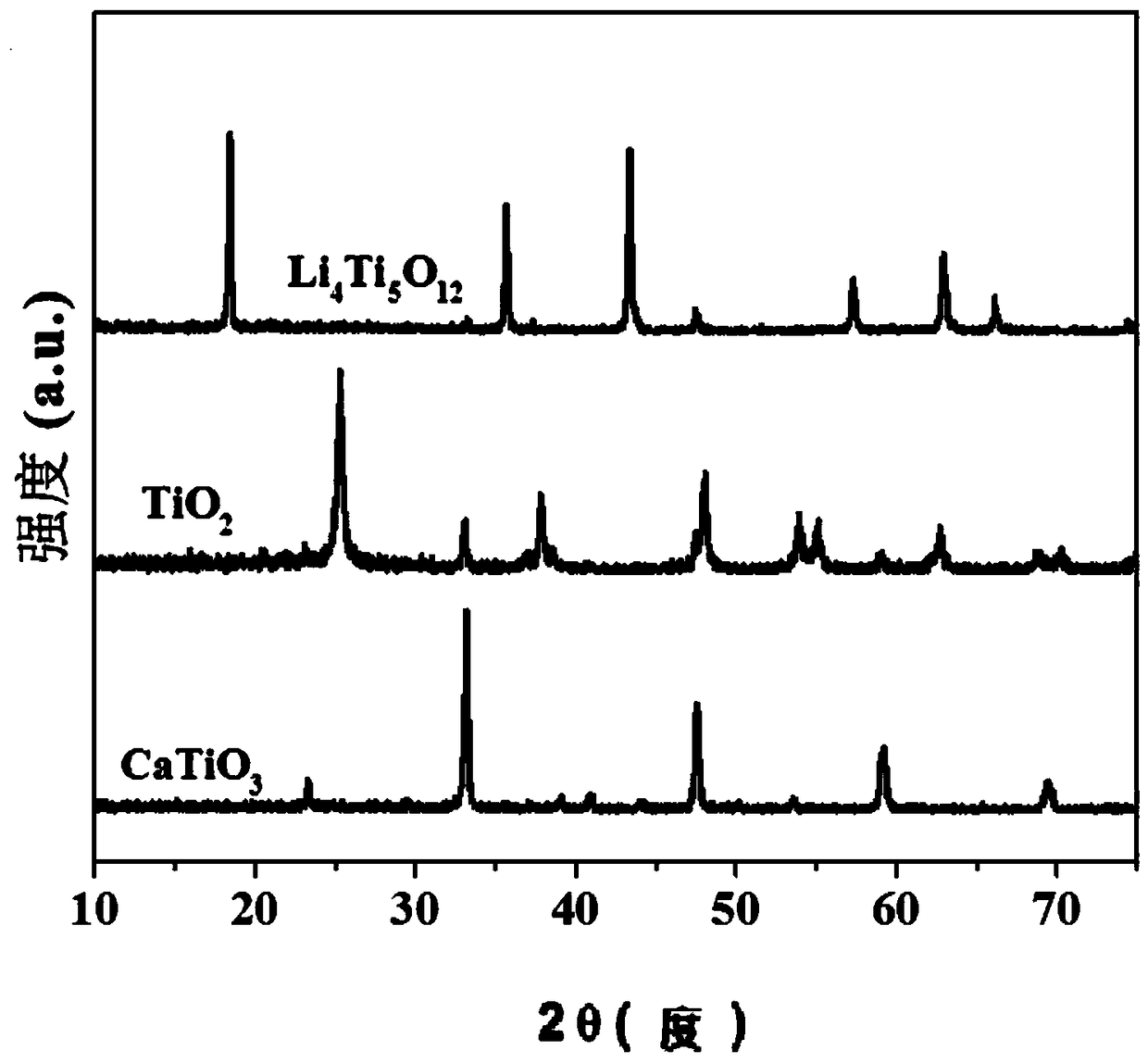

[0042] (1) Precursor cube CaTiO 3 preparation of

[0043] Weigh 0.11g of calcium chloride, 0.33g of butyl titanate, 0.5g of polyethylene glycol (PEG) 200 and 35mL of absolute ethanol and add them into a 50mL reaction kettle, and ultrasonically mix them for 30min at room temperature; Add 0.24g of sodium hydroxide under continuous stirring, and stir evenly. After the sodium hydroxide is dissolved, seal the reactor and heat it at 150°C for 20h. After the reactor is cooled to room temperature, filter it. and distilled water for three times, and dried overnight at 60°C to obtain the precursor cubic CaTiO 3 ;

[0044] (2) Hollow cube TiO 2 preparation of

[0045] Get the precursor cube CaTiO that 75mg step (1) makes 3 Place it in a 50mL reaction kettle, add 300mg of ethylenediaminetetraacetic acid disodium (EDTA-2Na), and add 30mL of water and 1...

Embodiment 2

[0052] The preparation method of the hollow cubic lithium titanate material provided in this embodiment includes the following steps:

[0053] (1) Precursor cube CaTiO 3 preparation of

[0054] Weigh 0.11g of calcium chloride, 0.33g of isopropyl titanate, 0.4g of polyethylene glycol (PEG) 1600 and 38mL of absolute ethanol and add them into a 50mL reaction kettle, and mix them uniformly by ultrasonication at room temperature for 30min; then Add 0.24g of sodium hydroxide under continuous stirring, and stir evenly. After the sodium hydroxide is dissolved, seal the reactor and heat it at 160°C for 18 hours. Wash with ethanol and distilled water three times, and dry overnight at 60 °C to obtain the precursor cubic CaTiO 3 ;

[0055] (2) Hollow cube TiO 2 preparation of

[0056] Get the precursor cube CaTiO that 100mg step (1) makes 3 Put it into a 50mL reaction kettle, add 600mg of dipotassium ethylenediaminetetraacetic acid (EDTA-2K), and add 40mL of water and 10mL of ethyle...

Embodiment 3

[0060] The preparation method of the hollow cubic lithium titanate material provided in this embodiment includes the following steps:

[0061] (1) Precursor cube CaTiO 3 preparation of

[0062] Weigh 0.11g of calcium chloride, 0.33g of butyl titanate, 0.5g of polyethylene glycol (PEG) 800 and 35mL of absolute ethanol and add them into a 50mL reaction kettle, and mix them uniformly by ultrasonication at room temperature for 30min; Add 0.24g of sodium hydroxide under continuous stirring, and stir evenly. After the sodium hydroxide is dissolved, seal the reactor and heat at 180°C for 15 hours. and distilled water for three times, and dried overnight at 60°C to obtain the precursor cubic CaTiO 3 ;

[0063] (2) Hollow cube TiO 2 preparation of

[0064] Get the precursor cube CaTiO that 75mg step (1) makes 3 Put it in a 50mL reaction kettle, add 400mg of ethylenediaminetetraacetic acid disodium (EDTA-2Na), and add 30mL of water and 10mL of ethylene glycol to form a mixture. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com