Circular saw machine automatic feeding system

A technology of automatic feeding and circular sawing machine, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc. It can solve the problems affecting the efficiency of bar cutting and processing, and affect the labor intensity of operators, so as to reduce labor intensity , Improve the efficiency of bar cutting and processing, and the effect of orderly feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

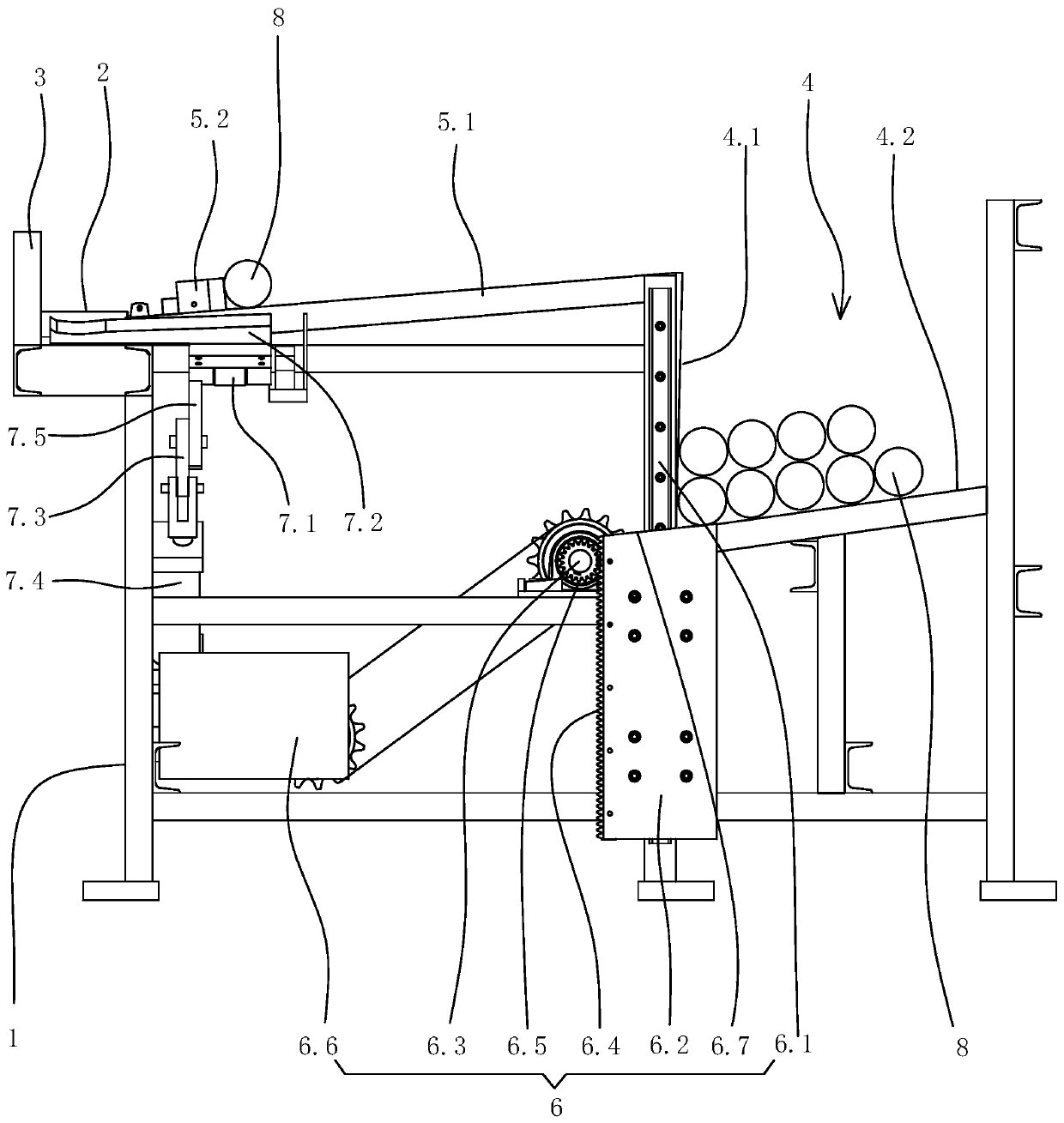

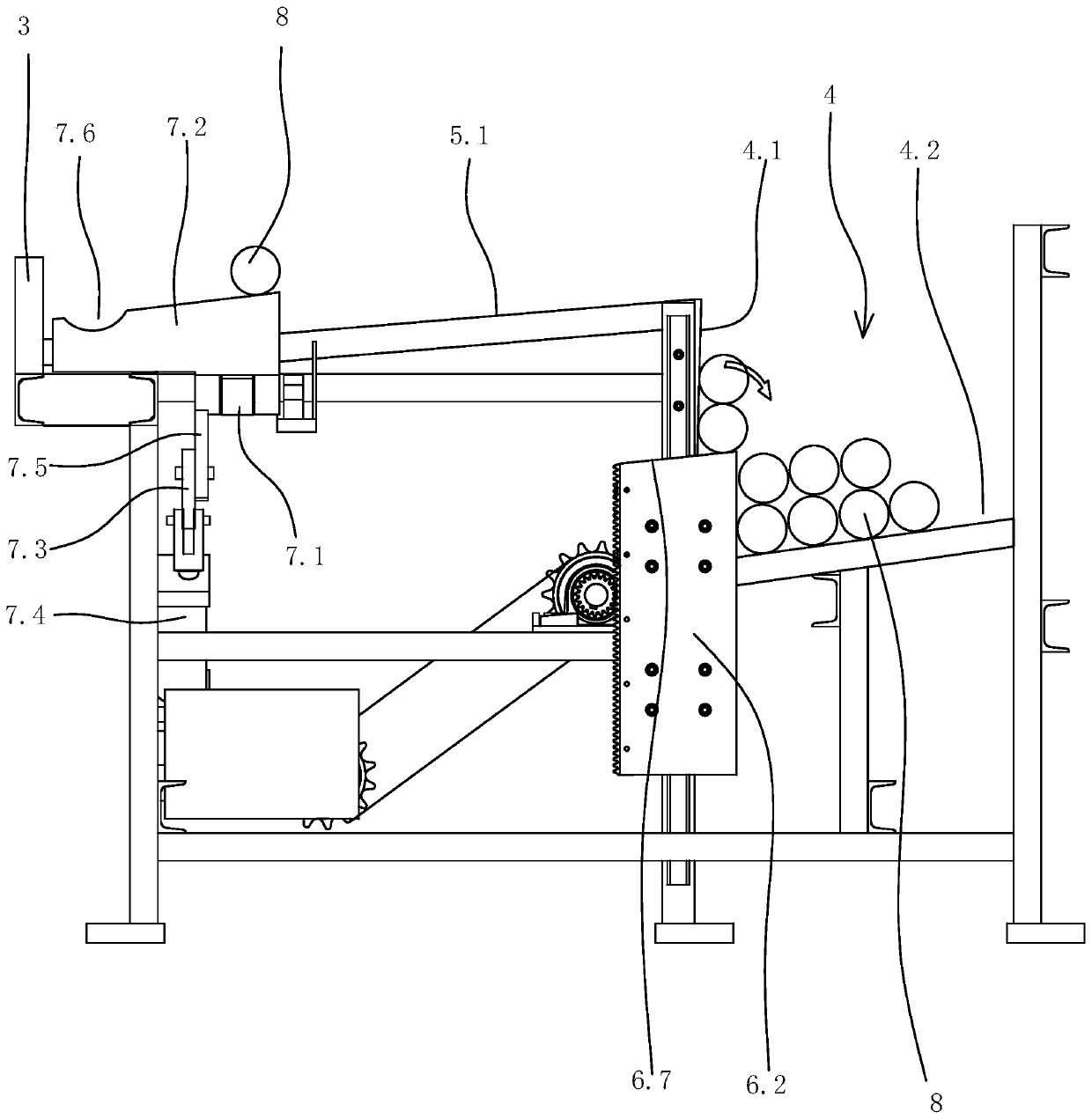

[0030] like figure 1 , figure 2 As shown, an automatic feeding system for a circular saw machine includes a base frame 1, a roller conveying line 2, a material rod placement groove 4, a material rod support frame 5, a material rod loading device 6 and a material rod loading device 7.

[0031] The roller conveying line is arranged on the chassis for supporting and conveying the material rods to be cut. The roller conveying line is made up of some rollers 2.1 on the bottom frame which are arranged in rotation.

[0032] The bottom frame is provided with several vertical stop rods 3 for the material rods on the limit roller conveying line. The vertical blocking rods are distributed sequentially along the conveying direction of the roller conveying line, and the vertical blocking rods and the roller conveying line are located on the same side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com