Flue gas purification treatment process for biomass power plant

A flue gas purification and treatment process technology, applied in the direction of gas treatment, climate change adaptation, climate sustainability, etc., can solve the problems of catalyst activity loss, equipment corrosion and dust deposition, high viscosity and strength, etc., to reduce tar adhesion, The effect of low maintenance cost and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

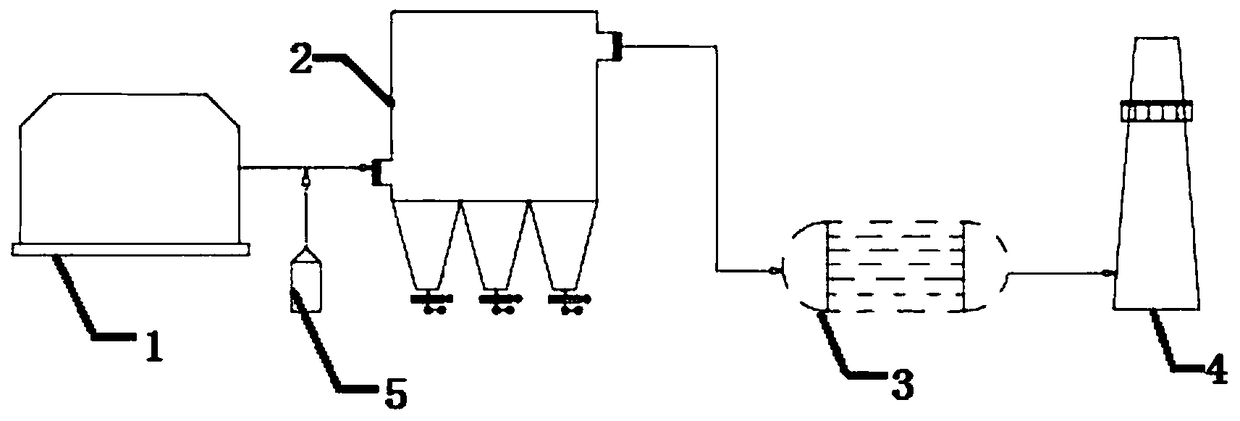

[0015] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description:

[0016] Such as figure 1 As shown, the biomass power plant flue gas purification treatment process includes the following steps:

[0017] The first step: fully mix the flue gas produced by burning biomass from the biomass boiler 1 of the biomass power plant with ammonia water 5, and then obtain the mixed high-temperature flue gas;

[0018] Step 2: Pass the mixed high-temperature flue gas through the catalytic ceramic fiber filter tube integrated denitrification and dust removal chamber 2 for denitrification reaction and dust removal treatment, so as to remove dust and nitrogen oxides in the mixed flue gas, and then obtain the treated flue gas smoke;

[0019] The third step: the treated flue gas is recovered through the waste heat boiler 3 to obtain purified flue gas after cooling;

[0020] Step 4: Discharge the purified flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com