A Ni-Co lithium manganate cathode material and a preparation method thereof

A technology of nickel-cobalt lithium manganate and cathode material, which is applied in the preparation of the nickel-cobalt lithium manganate cathode material and the field of nickel-cobalt lithium manganate cathode material, can solve the problems of poor cycle stability, poor high-rate capacity performance, etc. The effect of improving the specific capacity of charge and discharge, shortening the diffusion time, and fully compatible with industrial technologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

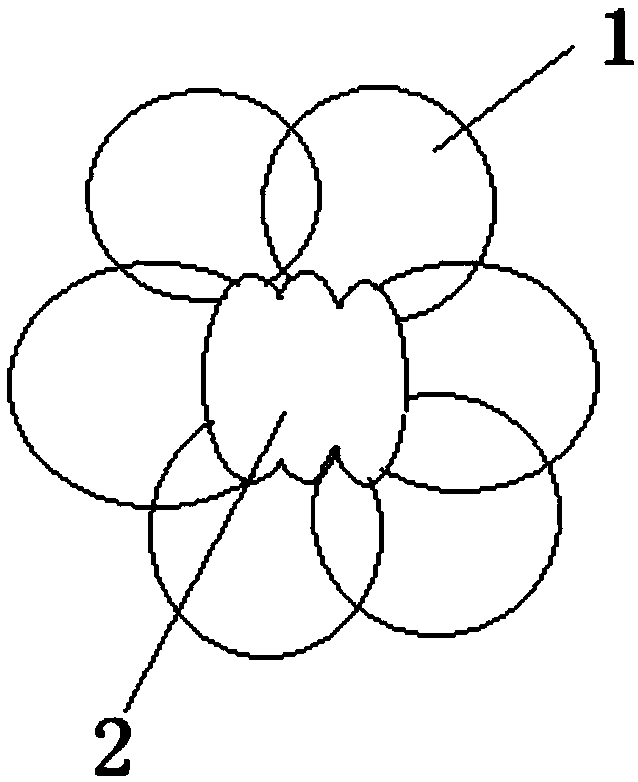

[0045] The preparation method of the above-mentioned nickel-cobalt lithium manganese oxide positive electrode material is specifically implemented according to the following steps:

[0046] Step 1, dispersing lanthanum nickelate nanocrystals in a dispersion solvent, and forming a highly dispersed suspension system of lanthanum nickelate nanocrystals by ultrasonic dispersion or high-energy stirring;

[0047] Among them, the size of lanthanum nickelate nanocrystals is 30nm-80nm, and the shape is granular or fibrous; it can be prepared by atomization thermal decomposition, CVD, sputtering deposition, high-energy ball milling, etc. Lanthanum nickelate nanocrystalline products.

[0048] The specific process of preparing lanthanum nickelate nanocrystals by atomization thermal decomposition method is as follows:

[0049] Weigh nickel acetate, lanthanum nitrate, and citric acid with a molar ratio of 1:1:1 and dissolve them in deionized water to obtain a solution with a mass concentra...

Embodiment 1

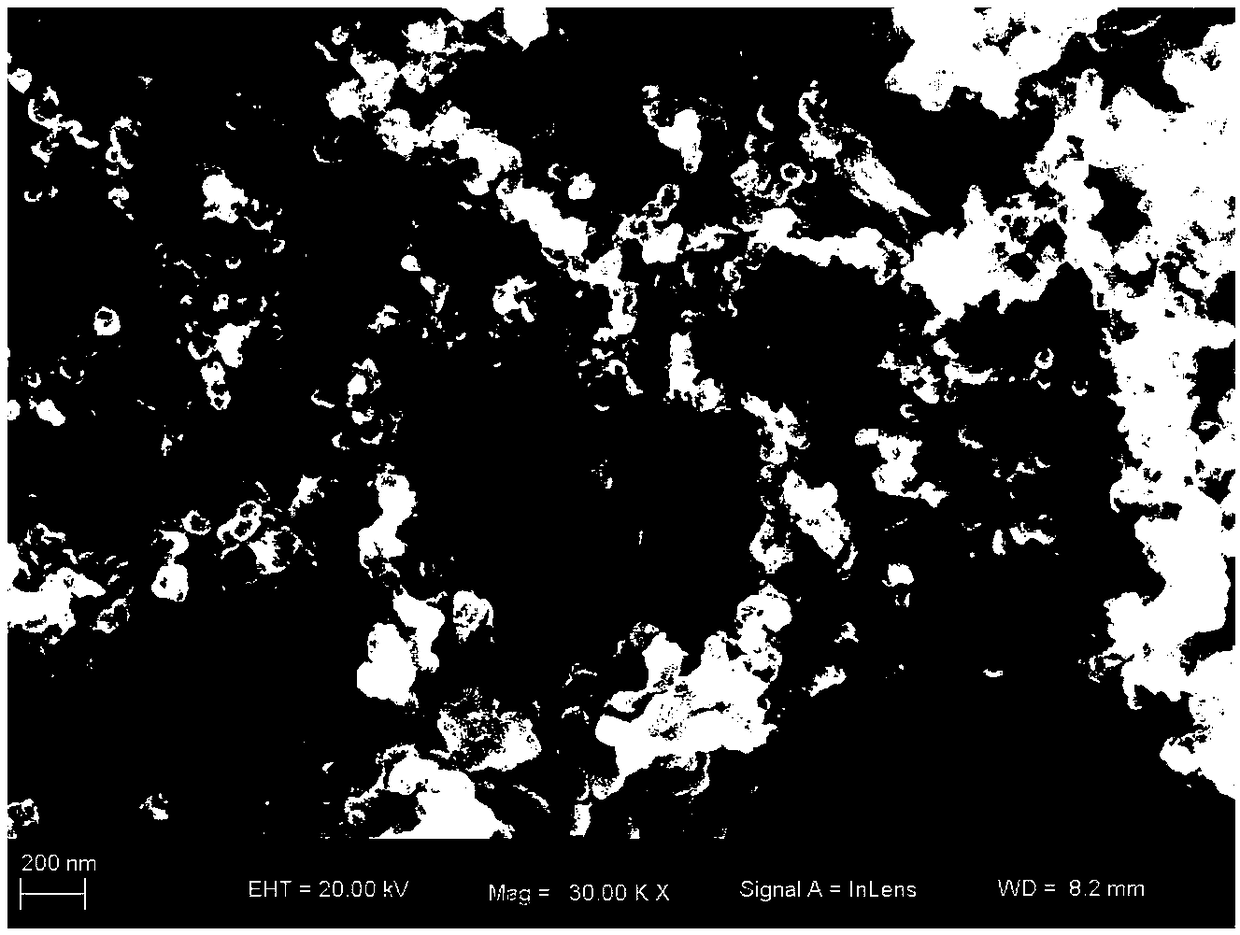

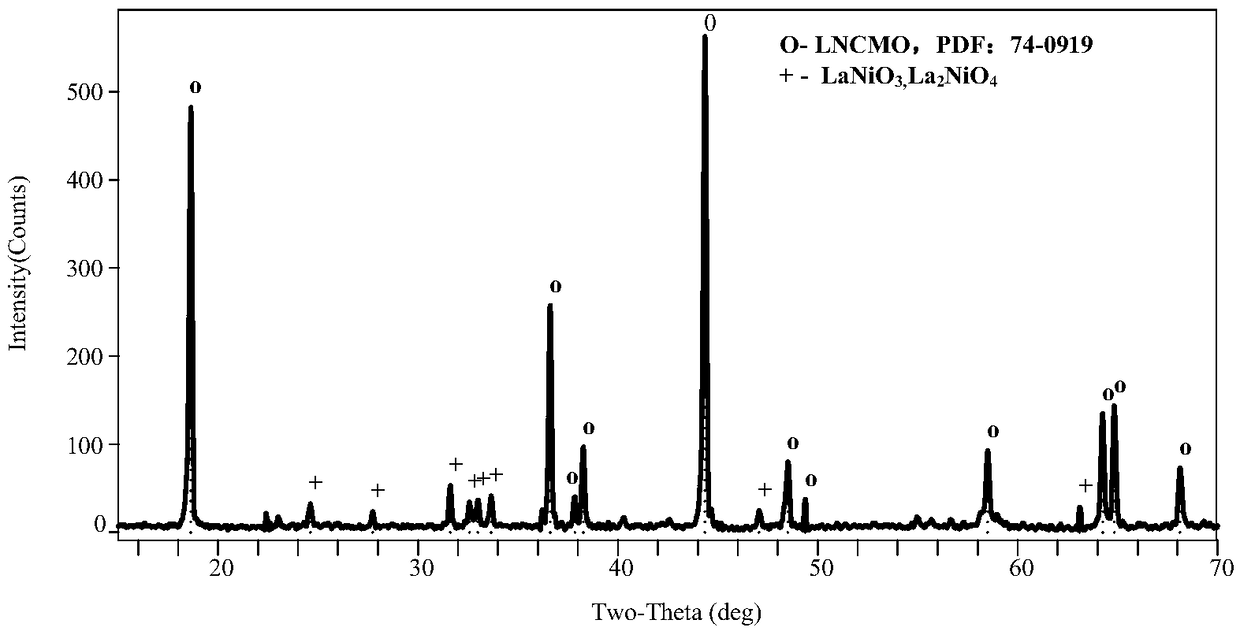

[0060] Step 1. Weigh nickel acetate, lanthanum nitrate, and citric acid with a molar ratio of 1:1:1 and dissolve them in deionized water to obtain a solution with a mass concentration of 5%. The atomized solution was transported to a tube furnace at 750°C at an average speed of 0.5cm / sec under air carrier gas, and the reaction product was collected in a collection filter at the end of the tube lumen to obtain lanthanum nickelate nanocrystals. Its SEM photos are as figure 2 As shown; using an ultrasonic reactor to disperse lanthanum nickelate nanocrystals in a mixed solvent of deionized water and ethylene glycol (deionized water: ethylene glycol mass ratio = 1:1), the formation of nickel acid with a mass concentration of 5% Highly dispersed suspension system of lanthanum nanocrystals;

[0061] Step 2. Mix the highly dispersed suspension system prepared in step 1 with the nickel-cobalt lithium manganate precursor powder (the nickel-cobalt lithium manganate precursor powder is ...

Embodiment 2

[0065] Step 1, using commercially available lanthanum nickelate nanocrystals (particle size is 30nm ~ 80nm), and using an ultrasonic reactor to disperse it in ethylene glycol to form a high dispersion of lanthanum nickelate nanocrystals with a mass concentration of 10% suspension system;

[0066] Step 2. Mix the highly dispersed suspension system prepared in step 1 with the nickel-cobalt lithium manganate precursor powder (the nickel-cobalt lithium manganese oxide precursor powder is made by mixing lithium carbonate, nickel oxide, cobalt carbonate, and manganese sulfate, and Ratio, Lithium Carbonate: Nickel Oxide: Cobalt Carbonate: Manganese Sulfate=1:0.6:0.2:0.2) Carry out ball milling and mixing in n-hexane, after mixing evenly, a mixed powder is obtained. In the mixed powder, lanthanum nickelate nanocrystals and The mass ratio of the nickel-cobalt-lithium-manganese-oxide precursor powder is 10%, and the mixed powder is sequentially dried and compacted under a pressure of 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com