Preparation method of electrochemical sensor for trace lead ion detection

A lead ion and electrochemical technology, applied in the field of preparation of electrochemical sensing, can solve the problems of complex preparation and low cost, and achieve the effect of simple preparation, low cost and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

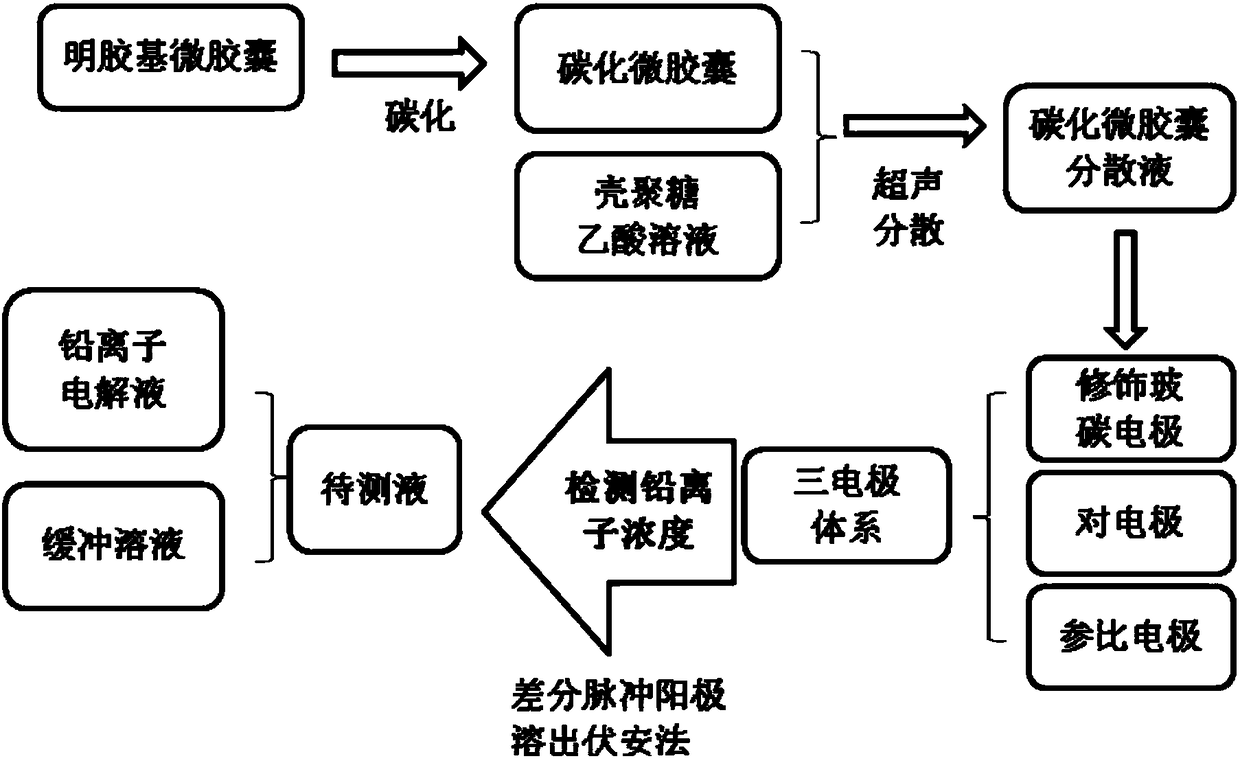

[0029] A preparation method for electrochemical sensing of trace lead ion detection, the specific process is shown in figure 1 :

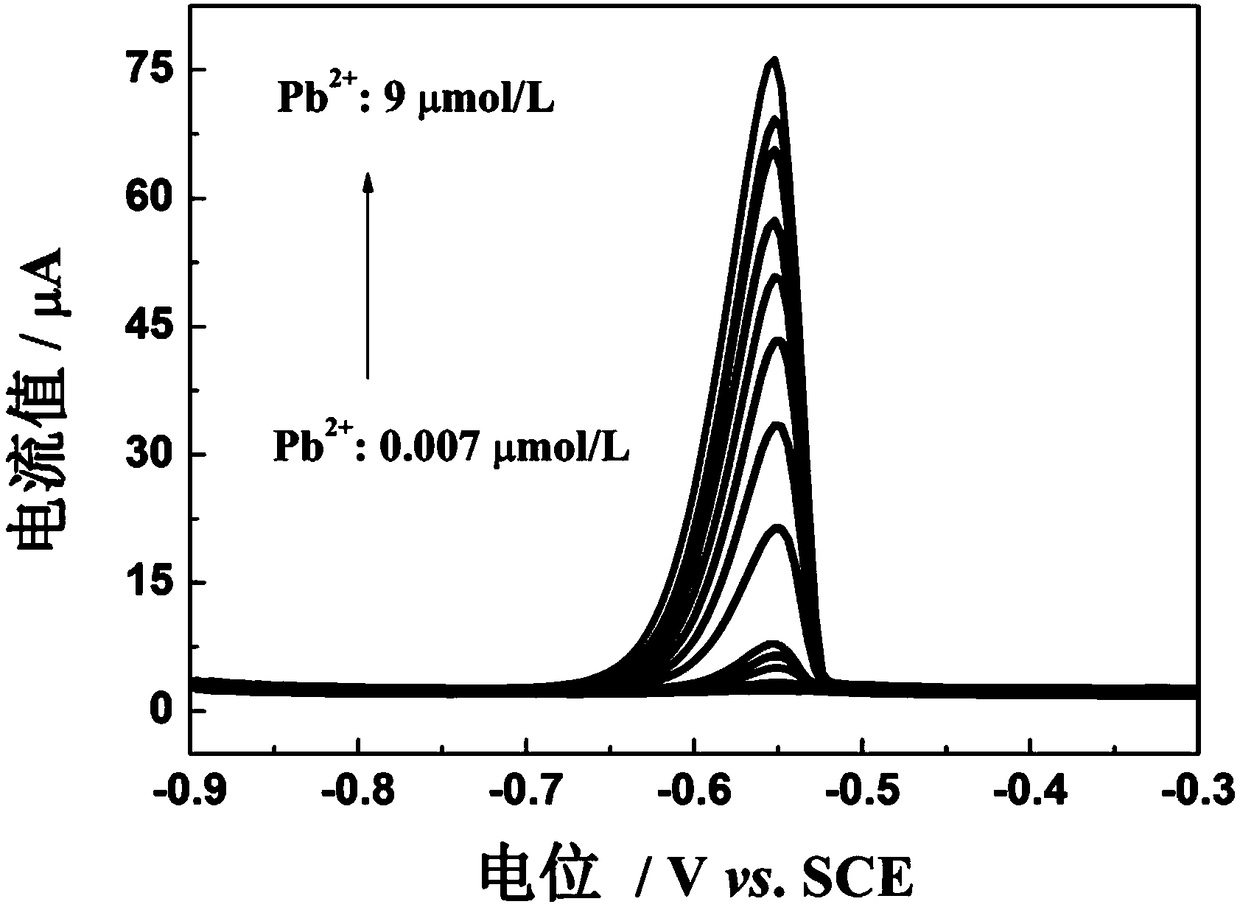

[0030] Gelatin-sodium carboxymethylcellulose-polysiloxane carboxylate prepared by the complex coacervation method (specifically refer to "Highblades spreadability of chlorpyrifos microcapsules prepared with polysiloxanesodium carboxylate / sodium carboxymethylcellulose / gelatin via complexcoacervation") after freeze-drying , see figure 2 a), from figure 2 In a, it can be seen that the uniform microporous structure of the microcapsules; under nitrogen protection, carbonization at 650°C for 8 hours, see figure 2 b, from figure 2 b It can be seen that the microcapsules shrink after carbonization, the pore size becomes smaller, and the specific surface area is larger. Take 2mg of carbonized microcapsule powder and ultrasonically disperse it in 2mL of 1mg / mL chitosan acetic acid solution, the mass fraction of acetic acid solution is 5%; take 5μL of...

Embodiment 2

[0032] The gelatin-carboxymethylcellulose sodium-sodium lauryl sulfate microcapsules prepared by the complex coacervation method were freeze-dried and carbonized at 600°C for 10 hours under the protection of nitrogen; 2 mg of the carbonized microcapsule powder was ultrasonically dispersed in In the chitosan acetic acid solution of 4mL 1mg / mL, the mass fraction of acetic acid solution is 1.0%; Take 5 μ L of carbonized microcapsule dispersion liquid as electrode material and modify the glassy carbon electrode after the surface is polished and ultrasonically cleaned, as the working electrode, The platinum sheet is used as the counter electrode, and the silver / silver chloride is used as the reference electrode to form a three-electrode system; Pb(CH 3 COO) 2The electrolyte solution is added to the ammonia gas-ammonium chloride buffer solution with a pH value of 5 to form a 5mL test solution; the three-electrode system is inserted into the test solution, and the -1.0V constant volt...

Embodiment 3

[0034] The gelatin-carboxymethylcellulose sodium-bis(2-ethylhexyl)sodium sulfosuccinate microcapsules prepared by the complex coacervation method were freeze-dried and carbonized at 800°C for 5 hours under nitrogen protection; 5 mg of the carbonized Ultrasonic dispersion of microcapsule powder in 1mL1mg / mL chitosan acetic acid solution, the mass fraction of acetic acid solution is 0.5%; take 5μL of carbonized microcapsule dispersion as electrode material to modify the surface of the glassy carbon electrode after polishing and ultrasonic cleaning , as the working electrode, the platinum sheet as the counter electrode, and the silver / silver chloride as the reference electrode; Pb(NO 3 ) 2 The electrolyte solution is added to the sodium dihydrogen phosphate-disodium hydrogen phosphate buffer solution with a pH value of 4, and the lead ion in the solution to be tested is enriched at a constant voltage of -0.4V, and the enrichment time is 500s; the differential pulse anode strippin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com