Double-head gas stove device and method

A gas stove and gas technology, which is applied to household stoves, heating methods, household stoves/stoves, etc., can solve the problems of easy burns, fires, explosions, and large overflows of plastic products, so as to avoid gas poisoning, ensure safety, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

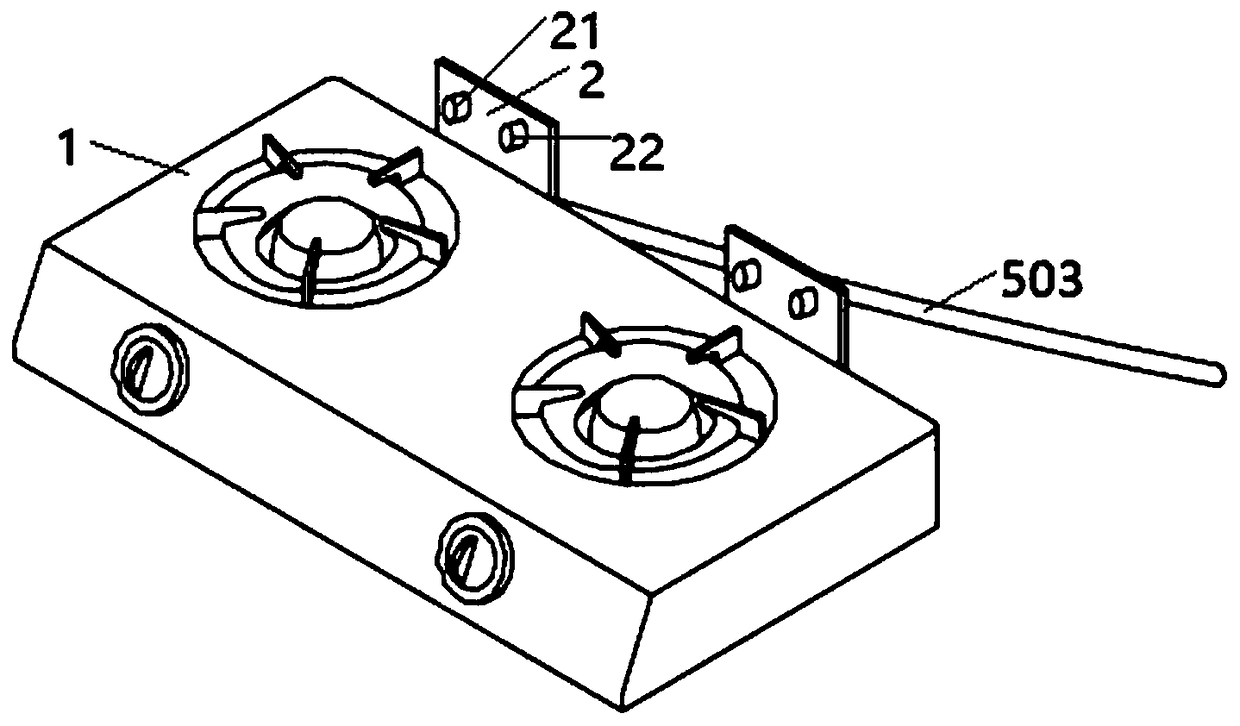

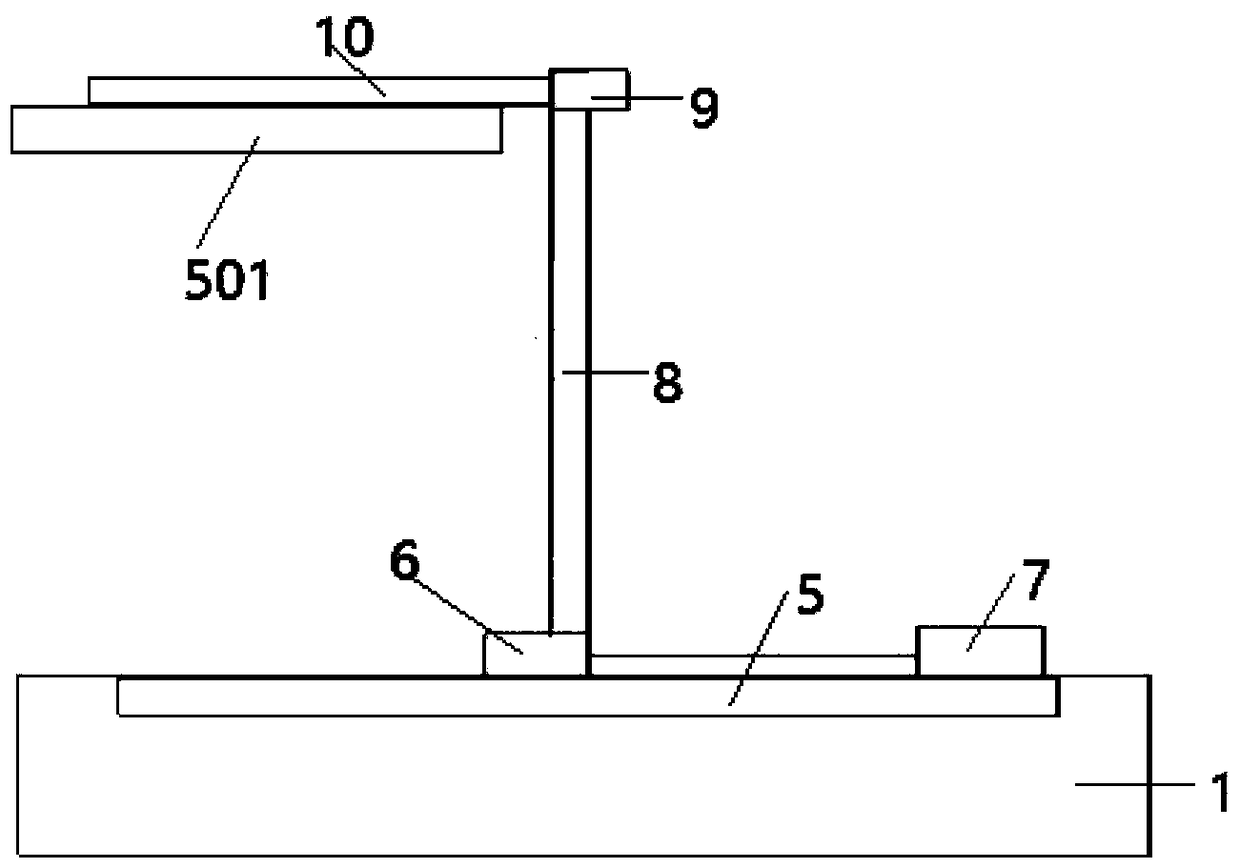

[0042] like figure 1 , figure 2 , Figure 5 The illustrated embodiment is a double-head gas stove device, comprising a gas stove 1, two detection boards 2 arranged on the gas stove, an infrared sensor 21 and a gas sensor 22 arranged on the lower surface of each detection board, and the control 3, the alarm 4, the horizontal guide rail 5 arranged on the rear side plate of the gas range, the support plate 6 arranged on the horizontal guide rail and the first cylinder 7 for driving the support plate to move laterally, the support plate located on the support plate Column 8, the second cylinder 9 located at the upper end of the support column and the horizontal plate 10 connected with the telescopic rod of the second cylinder; the lower surface of the horizontal plate is provided with an iron cover plate 501, and an electromagnet 502 is arranged in the horizontal plate; The cooking range is connected with the intake pipe 503, and the intake pipe is provided with a solenoid valv...

Embodiment 2

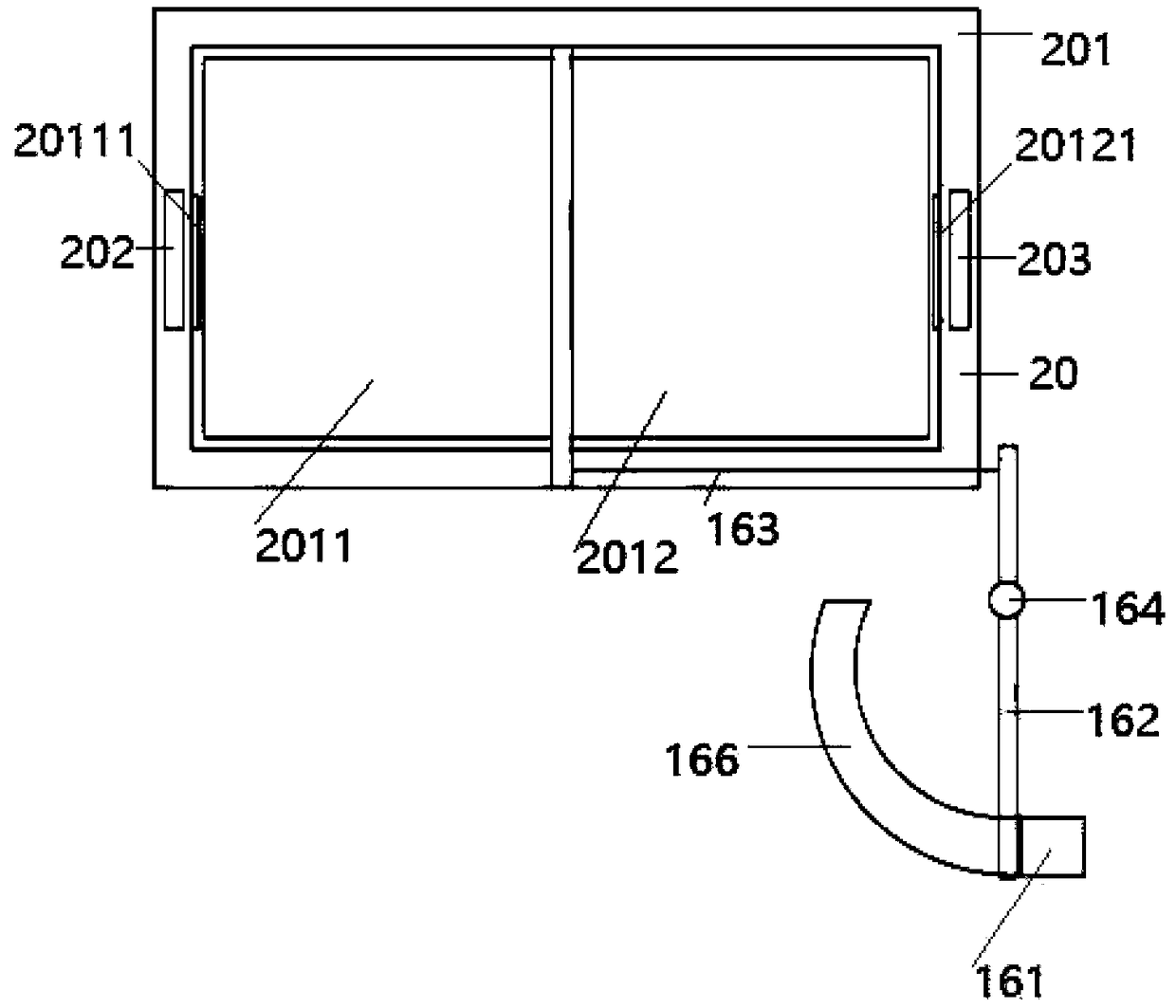

[0051] Embodiment 2 includes all structure and method parts of embodiment 1, such as image 3 Shown, also comprise window 20 and window opening mechanism 16, window comprises window frame 201, the left sash 2011 that is located on the window frame and right sash 2012, window opening mechanism comprises the wall that is located at the window lower right corner of the room where gas range is located The inner air bag 161, the vertical bar 162 that the lower end is connected with one end of the air bag, the rope 163 that is connected with the upper end of the vertical bar, the rope is connected with the lower right corner of the left window sash, and the vertical bar is connected with the wall by the rotating shaft 164, between the upper end of the rotating shaft and the vertical bar The distance between is less than the distance between the rotating shaft and the lower end of the vertical bar, and the ignition switch 165 of the airbag is electrically connected with the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com