Tungsten-rhenium-molybdenum alloy layer composite anode target material for X-ray tube and preparation method thereof

An X-ray tube and anode target material technology, which is applied in the field of powder metallurgy, can solve the problems of tungsten-rhenium alloy uniformity, coarse crystallization of the molybdenum alloy layer matrix, and high gas impurity content of the target plate, so as to reduce equipment investment and grain size. The effect of small and uniform structure and high qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

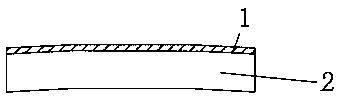

Image

Examples

preparation example Construction

[0027] A method for preparing a tungsten-rhenium-molybdenum alloy layer composite anode target for an X-ray tube, the specific steps comprising:

[0028] Step 1. Preparation of tungsten-rhenium pre-alloy powder to be reduced (mixing of tungsten-rhenium pre-alloy powder): Weigh tungsten powder and ammonium rhenate respectively according to a predetermined ratio, ammonium rhenate is made into ammonium rhenate solution, put tungsten powder into In the ammonium rhenate solution, the tungsten-rhenium pre-alloy powder to be reduced is obtained through stirring and heating and evaporating to dryness;

[0029] Step 2, reduction of tungsten-rhenium pre-alloyed powder: put the tungsten-rhenium pre-alloyed powder to be reduced into a reduction furnace for secondary reduction to obtain tungsten-rhenium pre-alloyed powder (ie: tungsten-rhenium pre-alloyed powder);

[0030] Step 3, compression molding: according to a predetermined ratio, the pre-prepared molybdenum alloy powder and the tung...

Embodiment 1

[0044] (1) Preparation of tungsten-rhenium pre-alloyed powder to be reduced: 12.9 kg of tungsten powder with a Fisher particle size of 1.7 μm and a purity of 99.95% and 575 g of ammonium rhenate powder with a purity of 99.99% were weighed. Pour ammonium rhenate powder into a heating and stirring pot filled with water to obtain a colorless transparent ammonium rhenate solution, and then pour tungsten powder into the ammonium rhenate solution. Then stir and heat, the stirring speed is 25r / min, and the stirring and heating time is 2 hours.

[0045] (2) Reduction of tungsten-rhenium pre-alloyed powder: put the mixed tungsten-rhenium pre-alloyed powder into a boat for hydrogen reduction treatment, first push the boat into a low-temperature zone for treatment, that is, the powder reacts at 320°C for 40 minutes , the hydrogen flow rate is 8L / h; then the boat is pushed into the high temperature zone for processing, that is, the powder is reacted at 650°C for 60min, and the hydrogen fl...

Embodiment 2

[0053] (1) Preparation of tungsten-rhenium pre-alloyed powder to be reduced: 12.95 kg of tungsten powder with a Fischer particle size of 2.4 μm and a purity of 99.95% and 190 g of ammonium rhenate powder with a purity of 99.99% were weighed. Pour ammonium rhenate powder into a heating and stirring pot filled with water to obtain a colorless transparent ammonium rhenate solution, and then pour tungsten powder into the ammonium rhenate solution. Then stir and heat, the stirring speed is 20r / min, and the stirring and heating time is 1.5 hours.

[0054] (2) Reduction of tungsten-rhenium pre-alloy powder: put the mixed tungsten-rhenium pre-alloy powder into a boat for hydrogen reduction treatment, first push the boat into the low temperature zone for treatment, that is, the powder reacts at 360°C for 30 minutes , the hydrogen flow rate is 6L / h; then the boat is pushed into the high temperature zone for processing, that is, the powder is reacted at 720°C for 40min, and the hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com