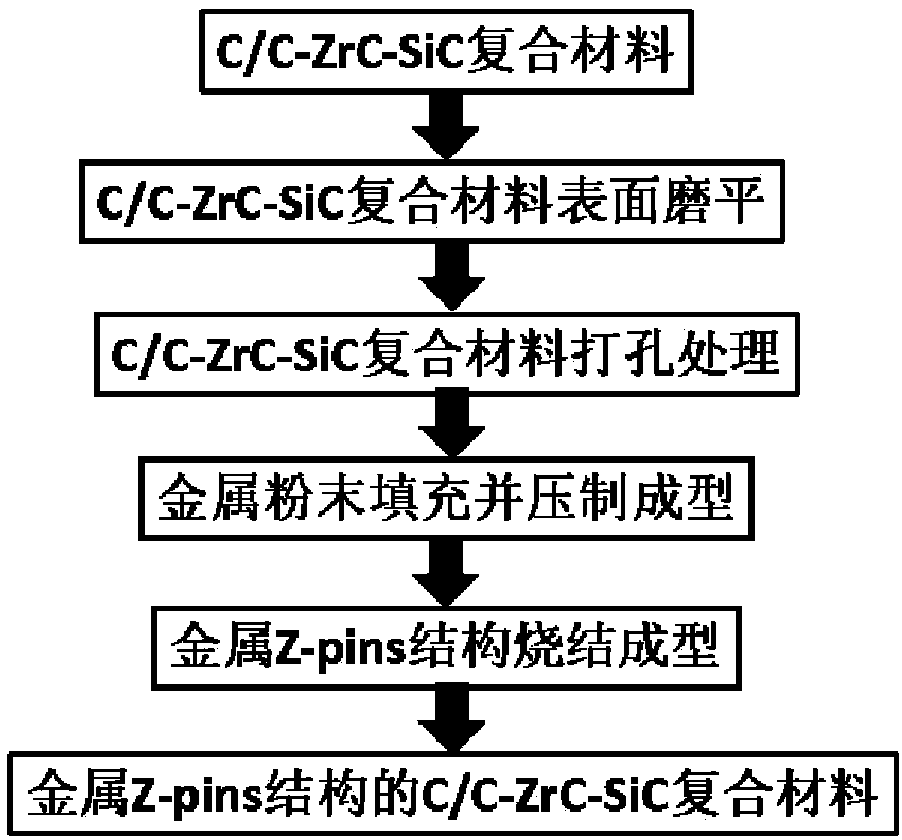

Preparation method of Z-pins-like metal rod enhanced carbon ceramic composite material

A technology of carbon-ceramic composite materials and metal rods, which is applied in the field of preparation of Z-pins-like metal rod-reinforced carbon-ceramic composite materials, can solve the problems of reducing the density of oxide protective films on the surface of substrates, and achieve high-temperature thermal resistance to chemical burning. Corrosion and mechanical erosion properties, low cost, and the effect of avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

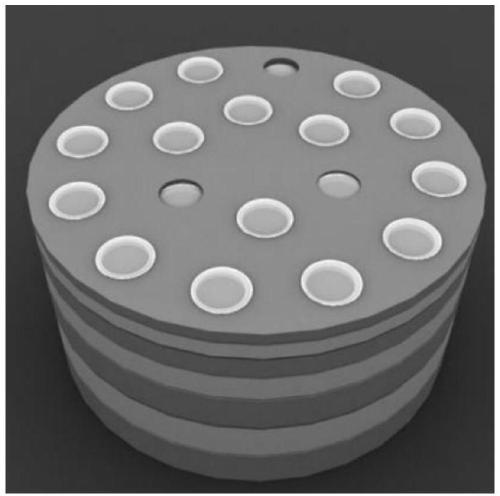

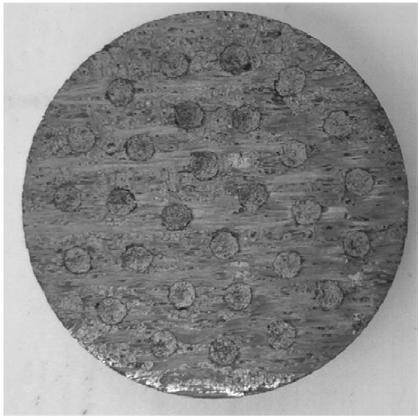

[0060] 1) Drill holes on the C / C-ZrC-SiC composite cylinder with a thickness of 10mm and a diameter of φ30mm; the punching equipment adopts a vertical machining center (JASU V-850); the hole diameter is 1.8mm, and the hole depth is 6mm, and the number of holes is 29, and the distribution density is 10%.

[0061] 2) Pretreat the V powder; select the powder with a particle size of 73 μm and a purity greater than 99.9% (Beijing Xingrongyuan Technology Co., Ltd.); and add 2% liquid paraffin to the selected powder as a forming agent (Sinopharm Chemical Reagent Co., Ltd.), pour absolute ethanol as the ball milling medium, use a planetary ball mill to wet-grind the metal powder and liquid paraffin under the protection of argon for 12 hours until uniform, and then dry it in a vacuum oven for 12 hours before use;

[0062] 3) Manually filling the prepared metal powder into the blind hole of the substrate and compacting it;

[0063] 4) Putting the pressed sample into a vacuum sintering ...

Embodiment 2

[0076] 1) Drill holes on the C / C-ZrC-SiC composite material cylinder with a thickness of 10mm and a diameter of φ30mm; the punching equipment adopts a vertical machining center (JASU V-850); the hole diameter is 1.8, and the hole depth is 4mm , and the number of holes is 29, and the distribution density is 10%.

[0077] 2) Pretreat the Zr-Al16 alloy powder; the particle size of the selected alloy powder is 73 μm and the purity is greater than 99.9% (Beijing Xingrongyuan Technology Co., Ltd.); and the selected powder is added with 2% liquid paraffin as a forming agent (Sinopharm Group Chemical Reagent Co., Ltd.), pour absolute ethanol as a ball milling medium, use a planetary ball mill to wet-grind metal powder and liquid paraffin under argon protection for 12h to uniformity, and then dry it in a vacuum oven for 12h before use;

[0078] 3) filling the prepared metal powder into the blind hole of the substrate, and pressing to form;

[0079] 4) Putting the pressed sample into a...

Embodiment 3

[0092] 1) Drill a C / C-ZrC-SiC composite cylinder with a thickness of 10mm and a diameter of φ30mm; the drilling equipment adopts a vertical machining center (JASU V-850); the diameter of the hole is 1.8, and the depth of the hole is 4mm , and the number of holes is 29, and the distribution density is 10%.

[0093] 2) Pretreat the Mo-Si-Ti mixed powder; the particle size of the selected molybdenum, silicon, and titanium powders is 200 mesh and the purity is greater than 99.9% (Beijing Xingrongyuan Technology Co., Ltd.); and the selected powders are placed on the planet The three kinds of metal powders were wet-milled for 12 hours under the type ball mill, and its ball-milling medium was absolute ethanol; then it was standby after drying in a vacuum oven for 12 hours; finally, 2% liquid paraffin was added as a forming agent (Sinopharm Group Chemical Reagent Co., Ltd.), Then pour absolute ethanol as the ball milling medium, and use a planetary ball mill to wet-grind the Mo-Si-Ti ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com