A driving system of an electronic track intelligent train and a power distribution method thereof

A technology of drive system and electronic track, which is applied in the field of rail transit, can solve problems such as unsatisfactory demand, achieve sufficient power, good economy, and improve vehicle dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

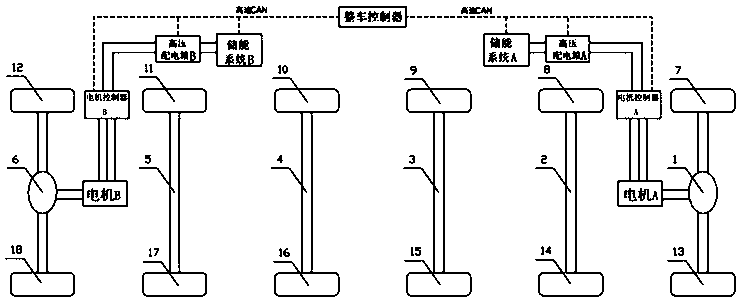

[0027] Such as figure 1 As shown, an electronic track intelligent train driving system includes a driving system A, a driving system B, a driving shaft A1, a driving shaft B6, a plurality of steering shafts 2 to 5, and two shafts (each driving shaft and each steering shaft) The rubber wheels 7-18 at the end, the drive system A is composed of a motor A, a motor controller A, a high-voltage distribution box A, and an energy storage system A connected in sequence, the motor A drives the drive shaft A1, and the drive system B is composed of Connected motor B, motor controller B, high-voltage distribution box B, and energy storage system B, motor B drives the drive shaft B6, and the CAN network of the drive system A and drive system B is connected to the vehicle controller. communication. The vehicle controller collects the data of vehicle speed, accelerator pedal and brake pedal to realize unified coordination, control and reasonable power distribution.

Embodiment 2

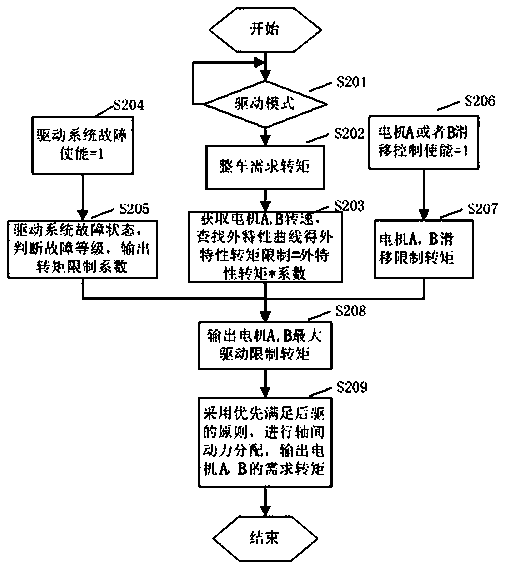

[0029] A power distribution method of an electronic track intelligent train drive system, such as figure 2 shown, including the following steps:

[0030] In the first step, the vehicle controller judges whether the vehicle is in the driving mode, and if it is in the driving mode, obtains and outputs the required torque of the vehicle according to the required torque MAP. The vehicle controller collects the state parameters of gear position, accelerator pedal, brake pedal and handbrake, and uses these state parameters to determine whether the vehicle is in the driving mode.

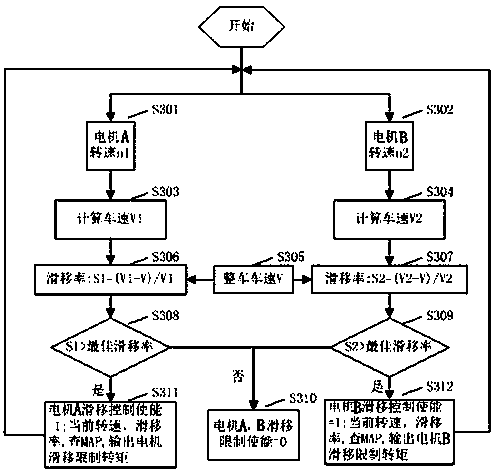

[0031] In the second step, according to the maximum drive limit torque of the motor, the power distribution is performed on the torque between the shafts, and the required torque of the motor is output to realize cooperative control. The maximum drive limit torque of the motor = min (external characteristic limit torque * drive system torque limit coefficient, slip limit torque); check the external chara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com