Mining dumper tank

A technology for mining dump trucks and boxes, which is applied in the direction of inclined load-carrying vehicles, etc., which can solve the problems of unreasonable distribution of working load, material accumulation in the box, and the rear center of gravity of the mining dump truck box, etc., to achieve simple structure, Improve the service life and solve the effect of material accumulation in the box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

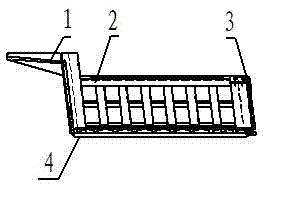

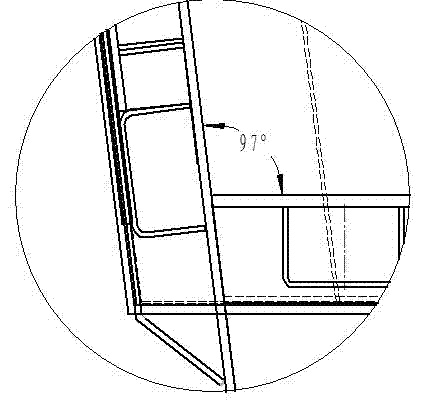

[0013] Such as Figure 1-2 As shown, the present invention is a mine dump truck box body, the box body includes a side panel assembly 2, a bottom panel assembly 4, a front panel assembly 1 and a rear panel assembly 3, and the front panel assembly 1 The rear panel assembly 3 is obliquely arranged at both ends of the side panel assembly 2, and the front panel assembly 1 cooperates with the bottom panel assembly 4 to form an angle of 97°. The invention adopts an italic box structure, and the front plate assembly and the bottom plate assembly form a 97° angle in the box, so that the center of gravity moves forward, the axle load distribution is more reasonable, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com