Light electric bus

An electric passenger car, light technology, applied in motor vehicles, electric power units, buses, etc., can solve the problems of inconvenient installation and removal of battery packs, large space occupied, heavy weight of batteries, etc., and achieve convenient installation and maintenance of batteries. , The effect of reasonable distribution of axle load and reasonable overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

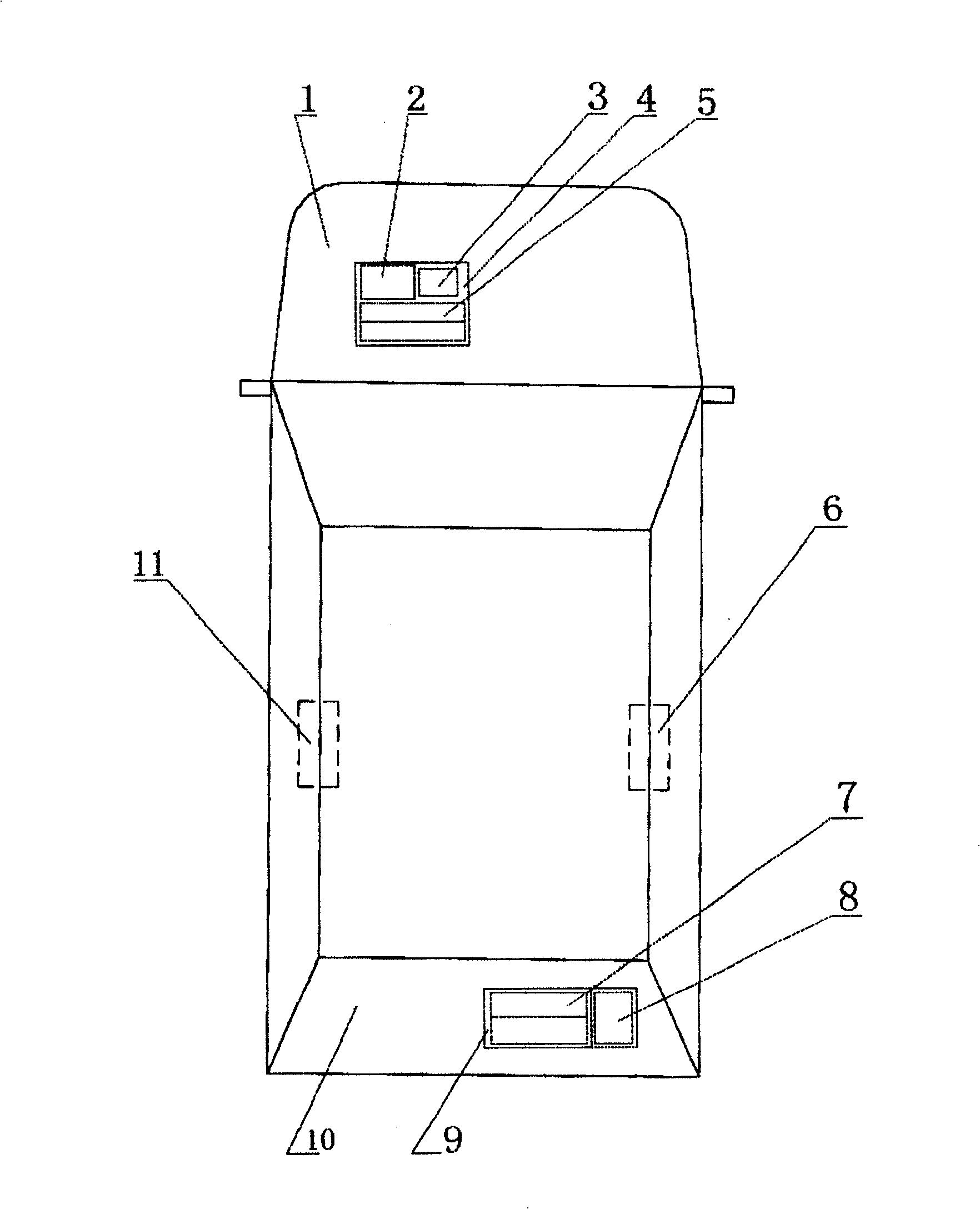

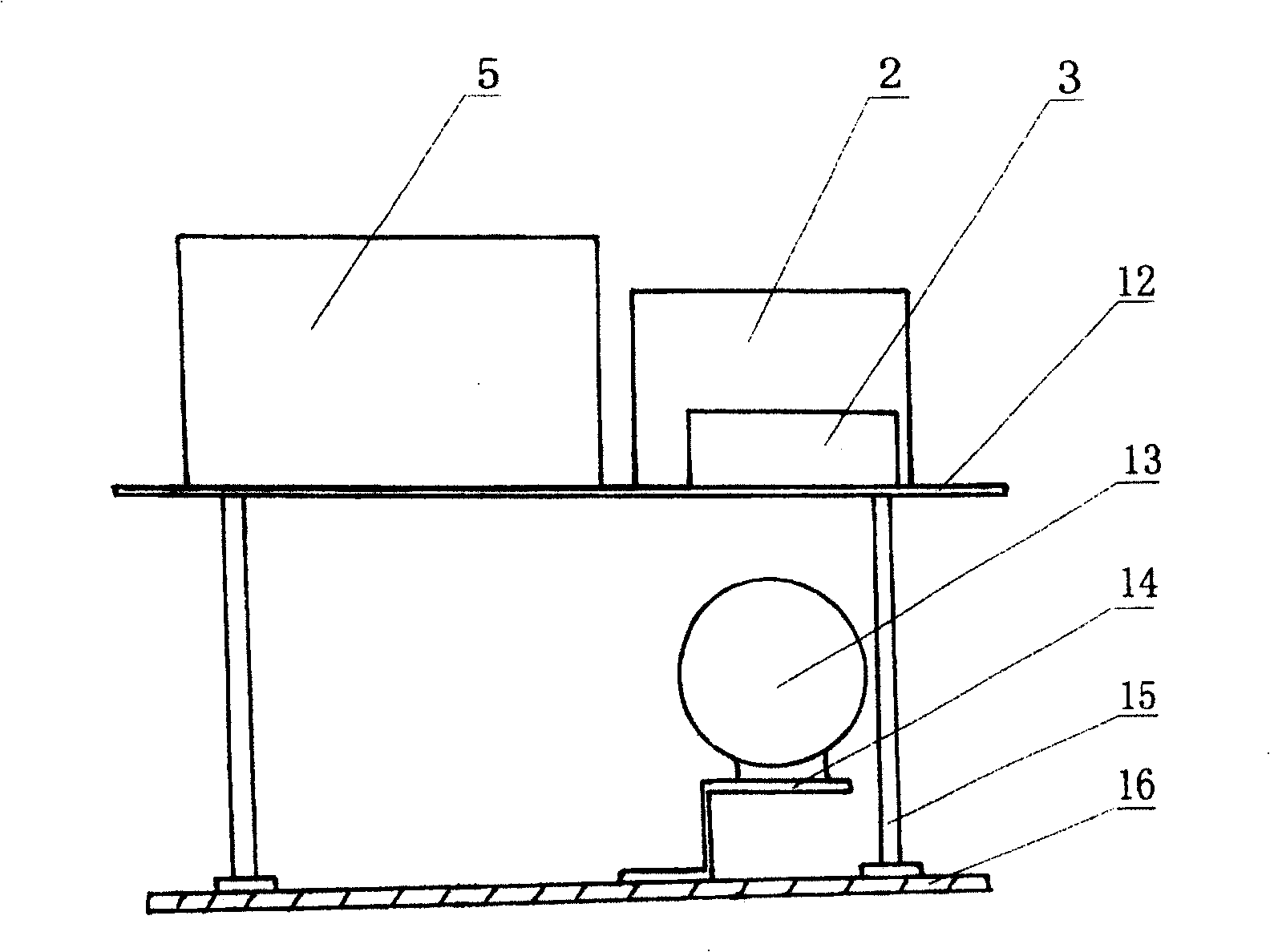

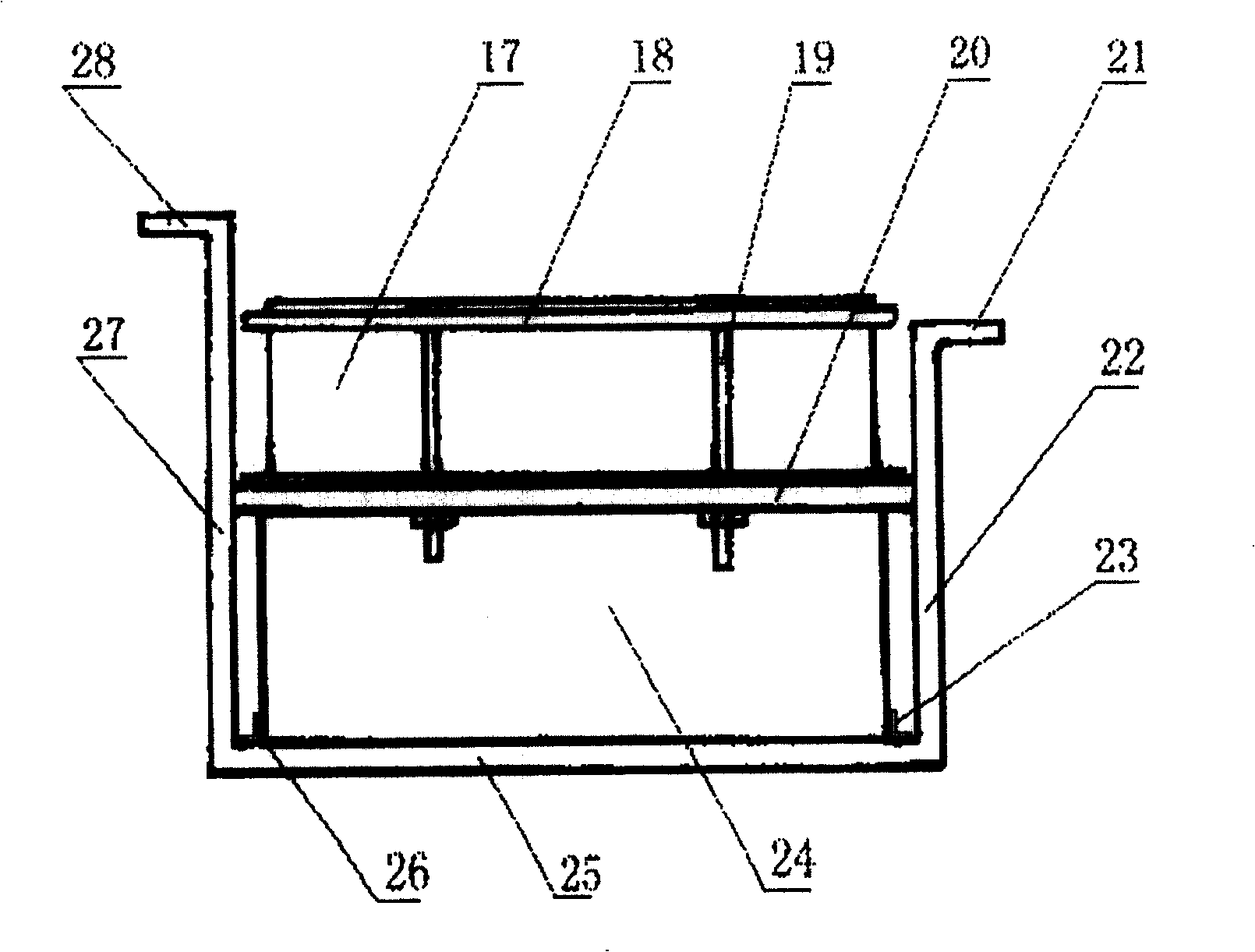

[0016] A light electric bus includes a power system, a drive system, a control system, a vehicle body, and a chassis braking system. The power battery pack of the power system is composed of three sets of six 12V battery packs connected in series, such as figure 1 , figure 2 As shown, one group is the front battery pack 5 arranged in the front compartment 1 of the vehicle, one group is the middle battery pack arranged on both sides of the drive shaft of the vehicle, and the other group is the rear battery pack arranged in the luggage compartment 10 Group 7. The front battery pack 5 , the DC / DC converter 3 , and the DC motor 13 of the drive system are arranged in the front compartment 1 . A support frame 4 is installed above the chassis 16 in the front cabin 1, the support frame 4 is made up of the support surface 12 at the top of the support foot 15 and the support foot 15, the bottom of the support foot 15 is fixedly connected with the chassis 16, and the support surface 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com