Burr polishing device for bending dies

A mold and burr technology, which is applied in the field of grinding machine grinding, can solve the problems of labor consumption and low efficiency, and achieve the effect of reducing labor force, improving efficiency and increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

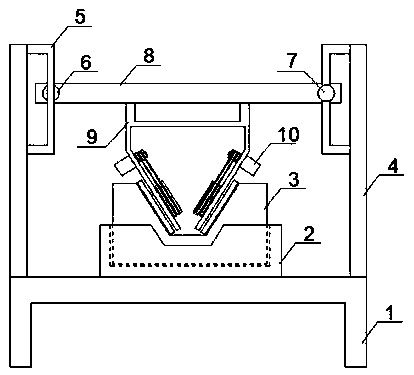

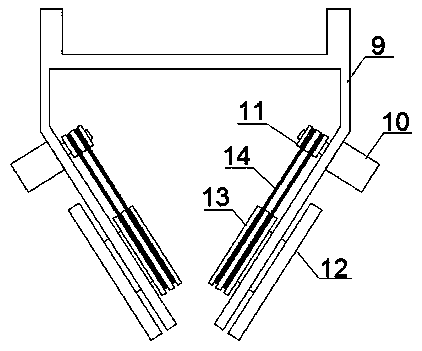

[0016] Such as Figure 1-3 As shown, the present invention discloses a bending mold burr grinding device, comprising: frame 1, fixture 2, mold 3, support plate 4, bracket 5, slide rail 6, ball screw module 7, slide plate 8, support Frame 9, DC motor 10, pulley one 11, grinding disc 12, pulley two 13, belt 14, described frame 1 is fixed with fixture 2 by bolts, mold 3 is clamped in described fixture 2, described The left and right ends of the upper plane of the frame 1 are respectively fixed with support plates 4 by bolts, and the relative positions of the opposite surfaces of the two support plates 4 are respectively fixed with brackets 5 by bolts. On the bracket at the left end of the frame 1 A slide rail 6 is fixed by bolts, and a ball screw module 7 is fixed by bolts on the bracket 5 at the right end of the frame 1, and a slide plate 8 is slidably installed on the slide rail 6, and the slide plate 8 and the ball The ball nuts of the lead screw module 7 are fixedly connecte...

Embodiment 2

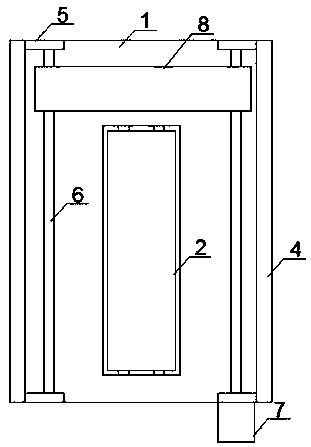

[0022] The structure of the bending mold burr grinding device in the first embodiment is basically the same as that in the first embodiment, the difference is that in this embodiment: by Figure 4 It can be seen that the groove of the mold 3 is in the shape of a cuboid, and the two legs of the support frame 9 are arranged vertically.

[0023] Therefore, as an optimization, the two legs of the support frame 9 in the present invention can be changed according to the shape of the groove on the mold 3, so as to complete the grinding.

[0024] The beneficial effects of the present invention: the ball screw module drives the slide plate to move on the slide rail, and the traditional manual movement is replaced by precise mechanical movement, which can improve the accuracy of grinding, improve the efficiency of grinding, and reduce the traditional manual grinding. Consuming labor; by making the two legs of the support frame parallel to the left and right inner walls of the groove of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com