Super-wide incidence angle microwave absorbing materials and a production method thereof

A wave absorbing material, incident angle technology, applied in conductive coatings, coatings, electrical components, etc., can solve the problems of increasing operation difficulty and platform cost, and achieve the effects of low cost, reduced storage space, and environmental protection of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

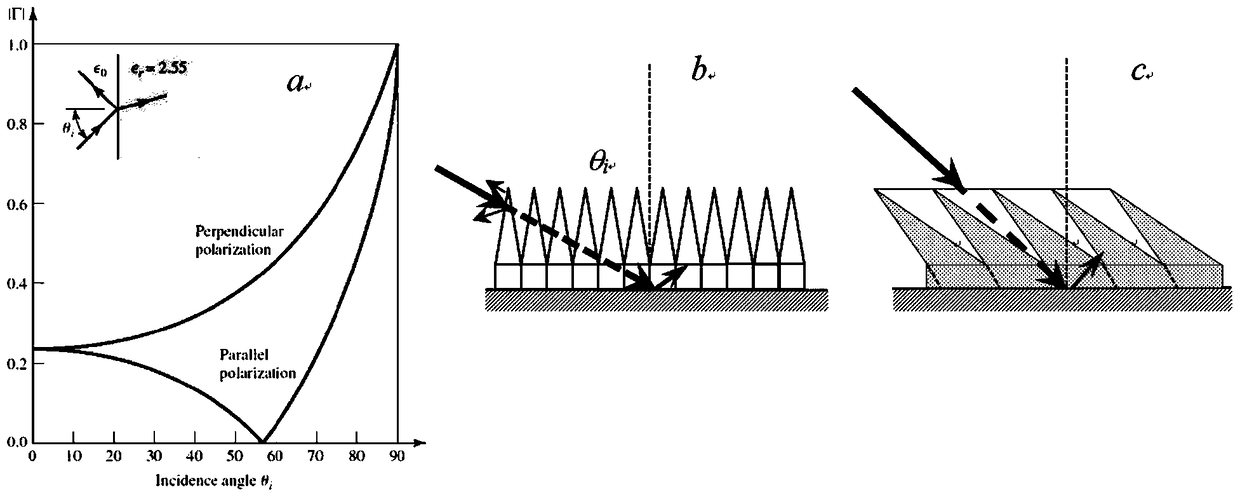

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Long-term use of wave-absorbing honeycomb with a height of 140 mm and a temperature of 180 °C

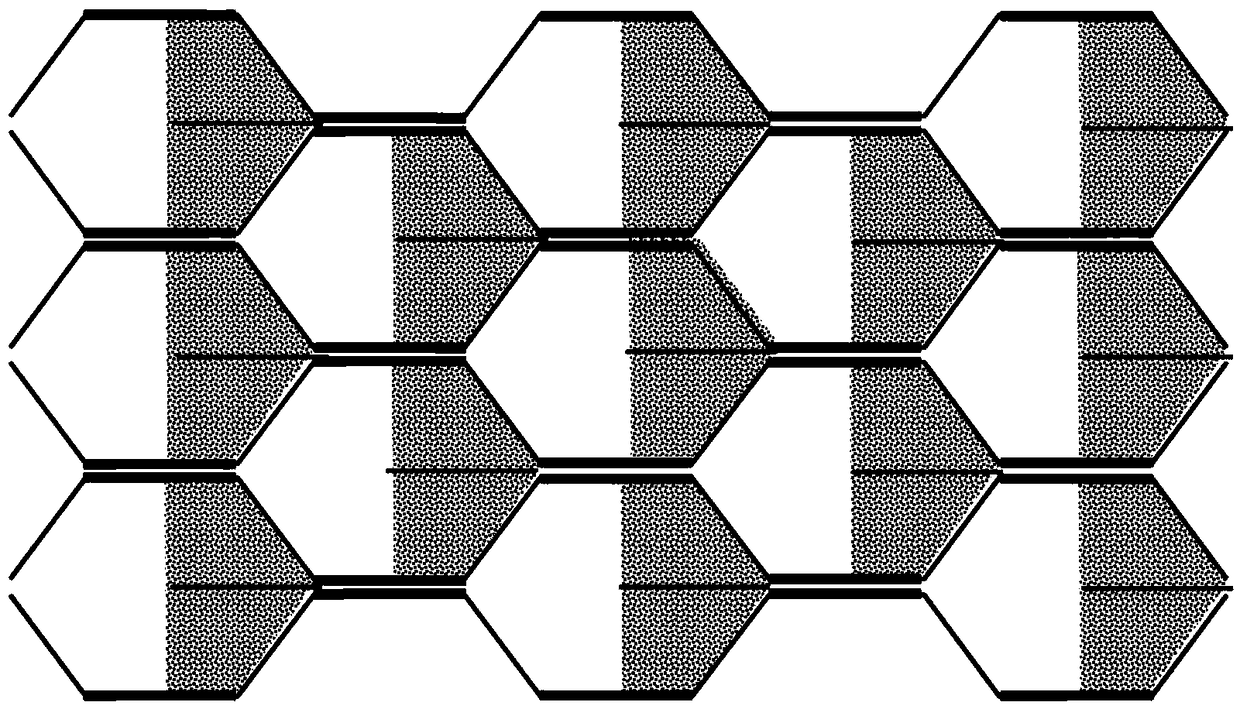

[0048] The surface density used in this embodiment is 80g / m 2 Nomex paper (Nomex paper) as substrate, need 25m 2 Flame Retardant Nomex Paper Production 1 m 2 The wave-absorbing honeycomb material weighs about 2.5kg and has a paper width of 0.9m. It produces a non-equilibrium hexagonal honeycomb with a side length of 0.55cm (the width of the node glue), using phenolic resin node glue, and the shape of the node glue is as follows: figure 2 As shown, the inclination angle is 45°. Superimposed and pressurized to form a 0.9m-high honeycomb substrate block and then sliced into 14cm-high slices, and then cut one side of the honeycomb into 7cm-deep wedges with an electric saw. Then stretch and fix the honeycomb structure on the bracket to be 2.5m long, 1.2m wide and 0.14m high.

[0049] Graphene conductive coating formula: graphene (900ºC expands 450 times graphite ...

Embodiment 2

[0052] Example 2: Long-term use of wave-absorbing honeycomb with a height of 600 mm and a temperature of 120 °C

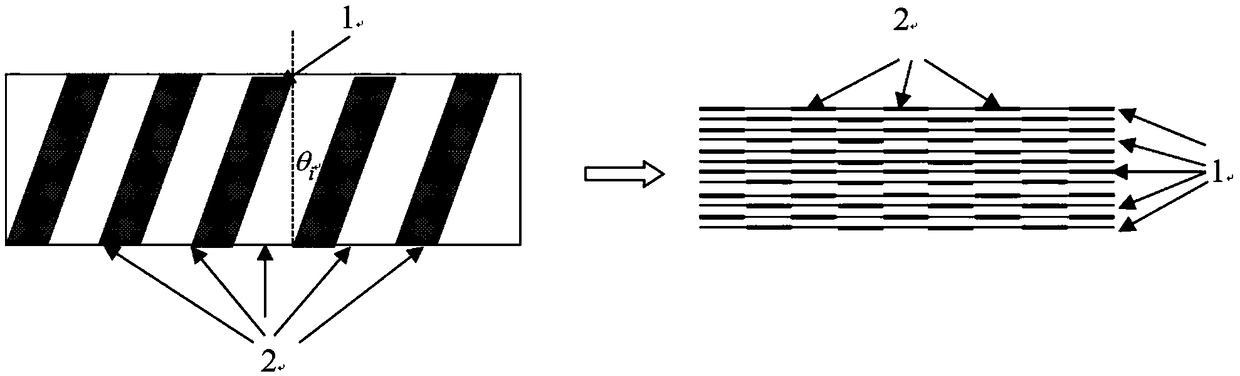

[0053] The surface density used in this embodiment is 180g / m 2 Kraft paper as the base material requires 38 m 2 Flame Retardant Kraft Paper Production 1 m 2 The absorbing honeycomb material weighs about 7.2kg and the paper width is 1.3m. First screen printed on paper as Figure 11 The conductive pattern of the inclined cone shown has a height of 0.6m, a width of the cone of 4.5cm, and an inclination angle of i =30°, the length of the cone is half of the height, and then cured at 180°C for 30 minutes. Produce non-equilateral hexagonal honeycombs with a side length of 1.5cm (the width of the joint glue) and 3cm (the distance between the joint glue), use phenolic joint glue, and use the silk screen to print the joint glue continuously. The shape of the joint glue is as follows: Figure 7 ), the inclination angle of node glue printing is 30º, the height of each ...

Embodiment 3

[0057] Example 3: 1200mm high 120°C low-frequency wave-absorbing honeycomb

[0058] This embodiment uses surface density 180g / m 2 Kraft paper as the base material requires 48 m 2 Kraft paper production 1 m 2 The wave-absorbing honeycomb material weighs about 8.7kg and has a paper width of 1.3m. It produces non-equilateral hexagonal honeycombs with a side length of 2.5cm (the width of the joint glue) and 5cm (the distance between the joint glue) and an inclination angle of 30°. Use phenolic joint glue, the shape of the joint glue is as Figure 7 ), the height of each section is 32cm, the distance between the two sections of joint glue is 12cm, the horizontal displacement of the upper and middle joint glue is 3.75cm, the upper and lower joint glue are aligned, and the sheets are cut into 1.2m high honeycomb substrate blocks after being superimposed and pressurized and cured, and then The honeycomb structure stretched and fixed on the support is 2.5m long, 1.2m wide and 1.2m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com