Inorganic filler composite PEO solid electrolyte material, preparation method thereof, and all-solid-state battery

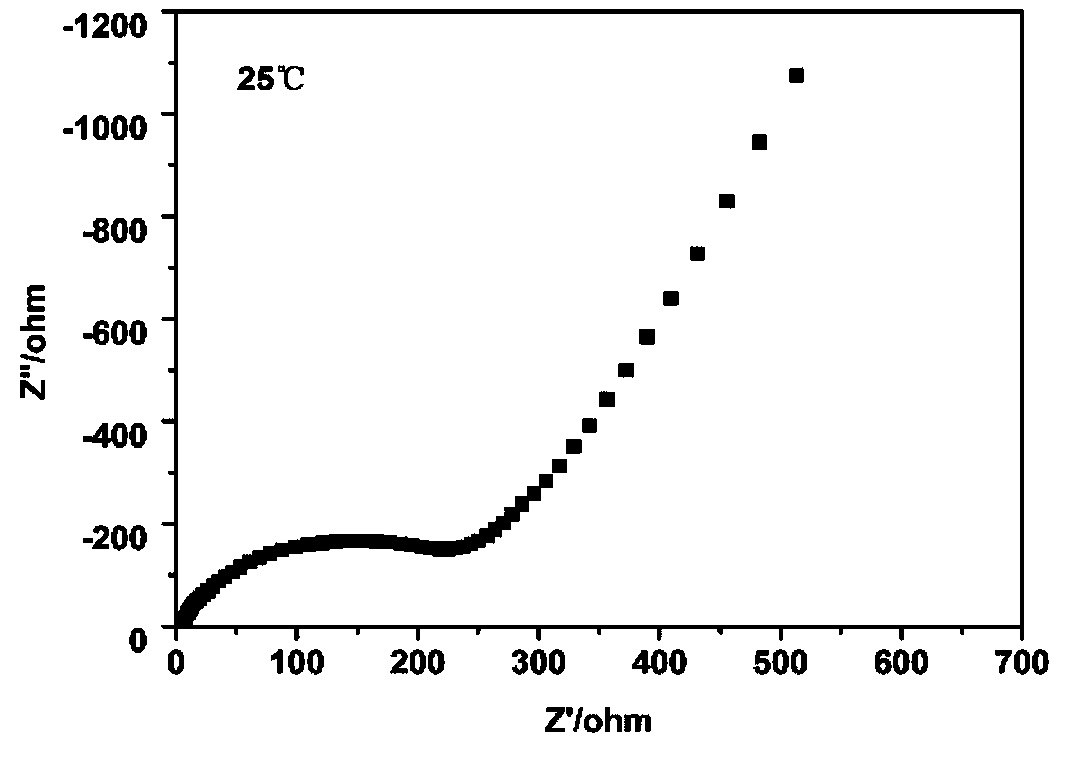

A solid electrolyte and solid electrolyte layer technology, applied in the field of lithium ion batteries, can solve problems such as low ionic conductivity, achieve high ionic conductivity, good mechanical properties, and improve interface stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention relates to a preparation method of an inorganic powder composite PEO solid electrolyte material and its application in an all-solid-state battery.

[0035] The inorganic filler composite PEO solid electrolyte material of the present invention consists of the following components by mass percentage:

[0036] Polyethylene oxide 5% to 80%;

[0037] Inorganic powder 1% to 80%;

[0038] Lithium salt 1% to 30%.

[0039] This method uses polyethylene oxide (PEO) as the matrix of solid electrolyte (the viscosity-average molecular weight Mv of PEO: 5×10 3 ~9×10 6 ). Inorganic electrolyte Li with high lithium-ion conductivity was chosen 7 La 3 Zr 2 o 12 (LLZO), Li 10 GeP 2 S 12 (LGPS), Li 2 O-Al 2 o 3 -TiO 2 -P 2 o 5One of (LATP) is used as an inorganic filler material, and lithium hexafluorophosphate, lithium tetrafluoroborate, lithium hexafluoroarsenate, lithium perchlorate, lithium bistrifluoromethanesulfonylimide, lithium difluoroborate, LiBOB, ...

Embodiment 1

[0042] Weigh 0.10g lithium perchlorate (LiClO 4 ) powder, 5.00g polyethylene oxide (PEO) powder and 0.20g Li 7 La 3 Zr 2 o 12 (LLZO) powder was vacuum-dried for 24 hours, and the viscosity-average molecular weight Mv of the PEO powder used was 9×10 5 . Lithium perchlorate (LiClO 4 ) powder was dispersed and placed in a 1L three-necked round-bottomed flask containing nitrile solution with reflux condensation and a stirrer and mechanically stirred for 10 to 30 minutes until completely dissolved, and then the dried Li 7 La 3 Zr 2 o 12 (LLZO) powder is gradually added to the uniformly mixed solution, and after ultrasonic dispersion for 30-60 minutes, it is completely dispersed in the solution under mechanical stirring. Stir mechanically for 12h to 24h to form a uniform suspension.

[0043] The above-mentioned vacuum drying process is as follows: the raw material powder is placed in a vacuum drying oven, the set temperature is 60°C, and it is taken out after drying for 24...

Embodiment 2

[0046] Weigh 0.10g lithium bistrifluoromethanesulfonylimide (LiTFSI) powder, 5.00g polyethylene oxide (PEO) powder and 0.20g Li 7 La 3 Zr 2 o 12 (LLZO) powder was vacuum-dried for 24h, and the viscosity-average molecular weight Mv of the PEO powder used was 6×10 5 . Disperse the vacuum-dried lithium bistrifluoromethanesulfonylimide (LiTFSI) powder in a 1L three-necked round-bottomed flask with reflux condensation and a stirrer containing the nitrile solution, and mechanically stir for 10 to 30 minutes until completely dissolved, then Then the dried Li 7 La 3 Zr 2 o 12 (LLZO) powder is gradually added to the uniformly mixed solution, ultrasonically dispersed for 30 to 60 minutes, then completely dispersed in the solution under mechanical stirring, and finally dry polyethylene oxide (PEO) is added and kept at 60°C to 90°C Stir mechanically for 12h to 24h to form a uniform suspension.

[0047] The above-mentioned vacuum drying process is as follows: the raw material powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com