A solvothermal reduction carbon-supported platinum-based catalyst for fuel cell and a preparation method and application thereof

A technology of fuel cell and solvothermal method, which is applied in the direction of fuel cells, battery electrodes, electrochemical generators, etc., and can solve problems such as high requirements for surfactants or protective agents and operating conditions, difficulty in mass production, and complicated operations , to achieve the effect of improving the utilization rate of precious metals, easy regulation and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

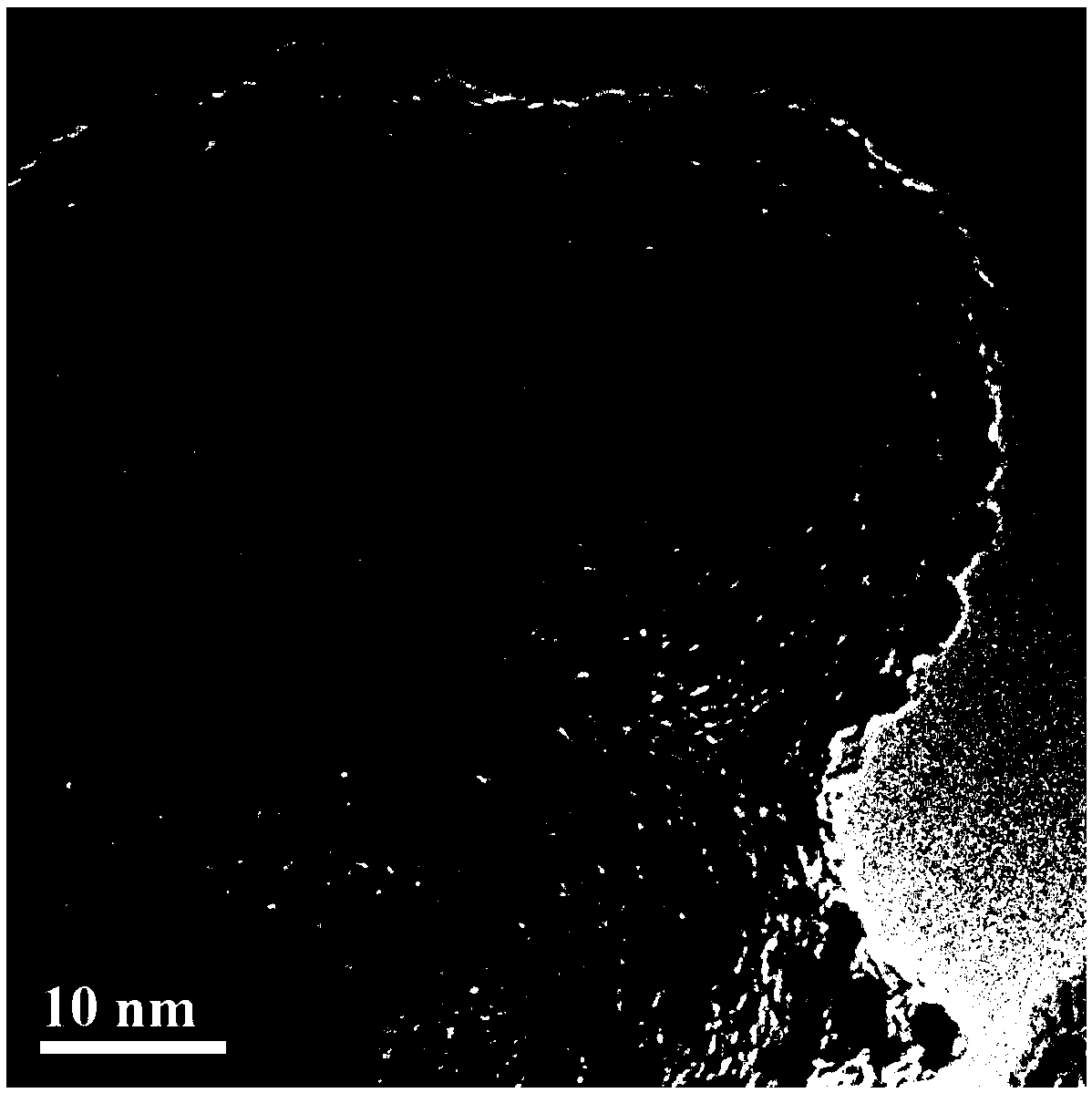

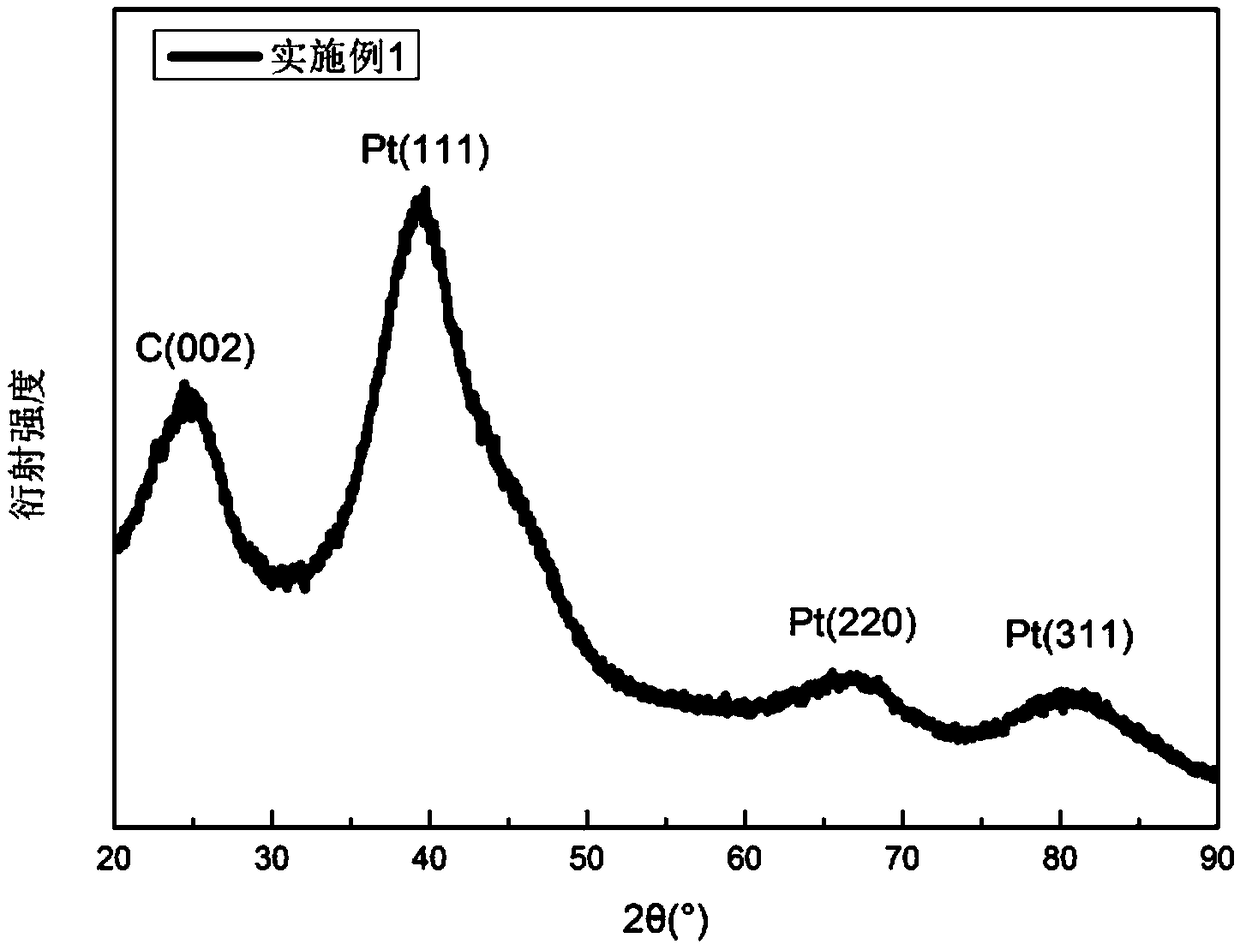

[0037] A method for preparing a carbon-supported platinum-based catalyst applied to a fuel cell, comprising the following process steps:

[0038] 1) Weigh 80 mg of the purchased XC-72 with an analytical balance, add 40.00 mL of ethylene glycol solution, and disperse alternately by ultrasonication and stirring for more than 1 hour until XC-72 is evenly dispersed in the ethylene glycol solution;

[0039] 2) Add 5.25mL chloroplatinic acid ethylene glycol solution (3.81mg / mL) dropwise, and stir to disperse for more than 3h;

[0040] 3) Add dropwise 1mol / L NaOH ethylene glycol solution, adjust the pH value of the solution obtained in step 2) to 11, and fully disperse to obtain a mixed solution;

[0041] 4) Place the mixed solution obtained in step 3) in a high-pressure sealed reaction vessel, heat it to 140°C with an external source, and heat it for 3 hours to obtain a reaction solution; after the reaction solution is naturally cooled to room temperature, add 0.5mol / L drop by drop ...

Embodiment 2

[0048] A method for preparing a carbon-supported platinum-based catalyst applied to a fuel cell, comprising the following process steps:

[0049] 1) Weigh 80 mg of the purchased XC-72 with an analytical balance, add 40.00 mL of ethylene glycol solution, and disperse alternately by ultrasonication and stirring for more than 1 hour until XC-72 is evenly dispersed in the ethylene glycol solution;

[0050] 2) Add 5.25mL chloroplatinic acid ethylene glycol solution (3.81mg / mL) dropwise, and stir to disperse for more than 3h;

[0051] 3) Add dropwise 2mol / L KOH ethylene glycol solution, adjust the pH value of the solution obtained in step 2) to 13, and fully disperse to obtain a mixed solution;

[0052] 4) Place the mixed solution obtained in step 3) in a high-pressure sealed reaction vessel, heat it to 140°C with an external source, and heat it for 2 hours to obtain a reaction solution. After the reaction solution is naturally cooled to room temperature, add 0.5mol / L dropwise HCl ...

Embodiment 3

[0058] A method for preparing a carbon-supported platinum-based catalyst applied to a fuel cell, comprising the following process steps:

[0059] 1) Weigh 80 mg of purchased XC-72 with an analytical balance, add 35 mL of ethylene glycol solution, and disperse alternately by ultrasonication and stirring for more than 1 hour until XC-72 is uniformly dispersed in the ethylene glycol solution;

[0060] 2) Add 10.5mL chloroplatinic acid ethylene glycol solution (3.81mg / mL) dropwise, and stir to disperse for more than 3h;

[0061] 3) Add 1mol / L NaOH ethylene glycol solution dropwise, adjust the pH value of the solution obtained in step 2) to 13, and fully disperse to obtain a mixed solution;

[0062] 4) Place the mixed solution obtained in step 3) in a high-pressure sealed reaction vessel, heat it to 140°C with an external source, and heat it for 5 hours to obtain a reaction solution. After the reaction solution is naturally cooled to room temperature, add 0.5mol / L dropwise HNO 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com