Preparation method of carbon-coated single crystal ternary cathode material

A carbon-coated single crystal and positive electrode material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of incomplete coating, can not prevent the erosion of electrolyte to materials, etc., achieve low residual rate and improve cycle stability The effect of improving the magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

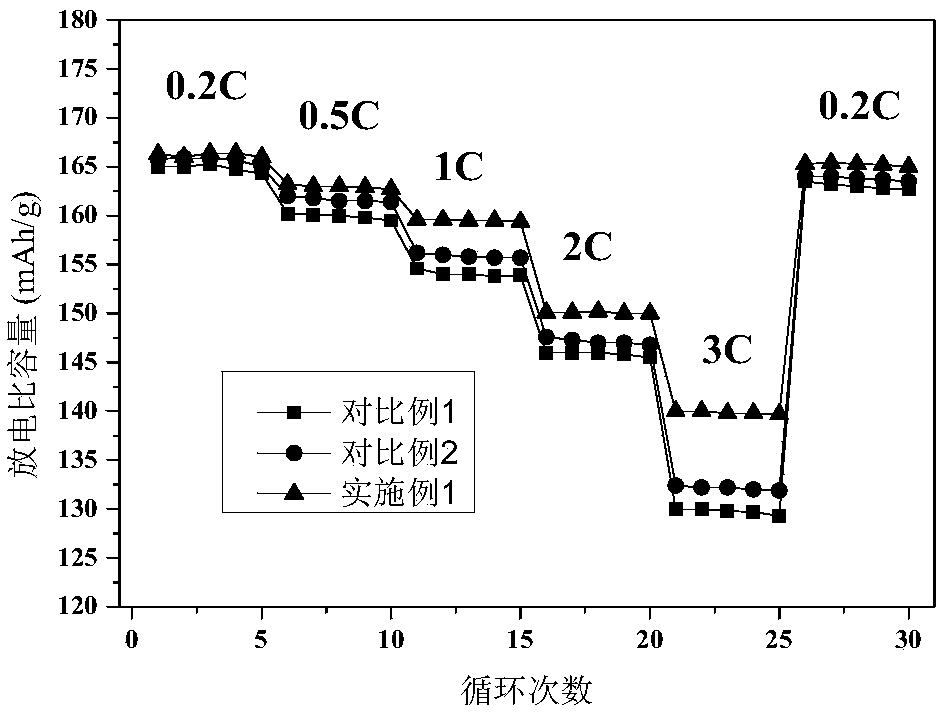

Embodiment 1

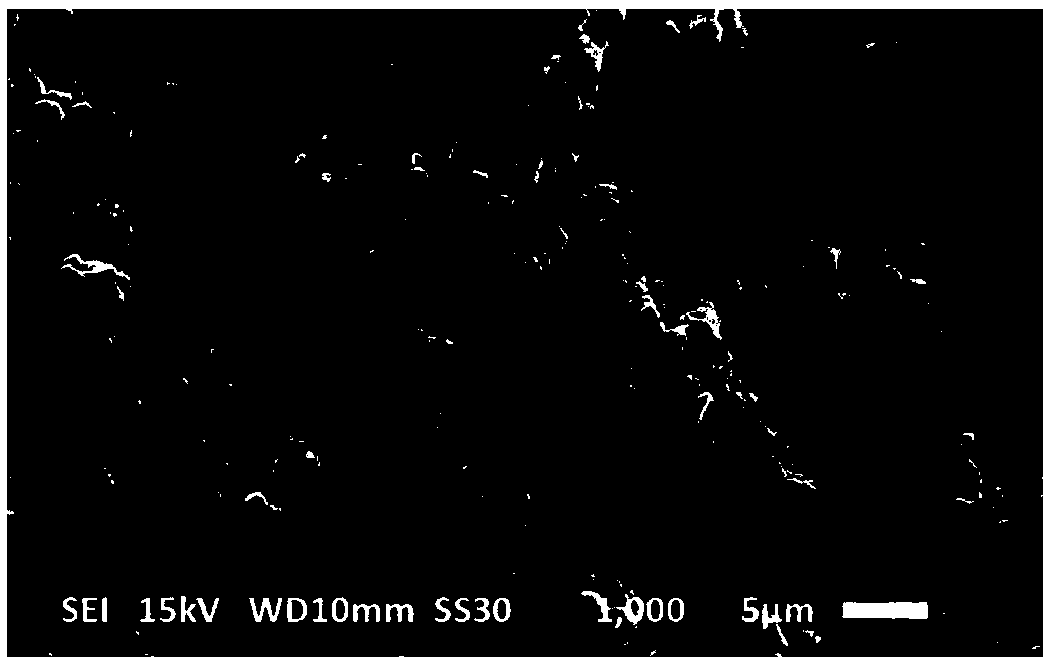

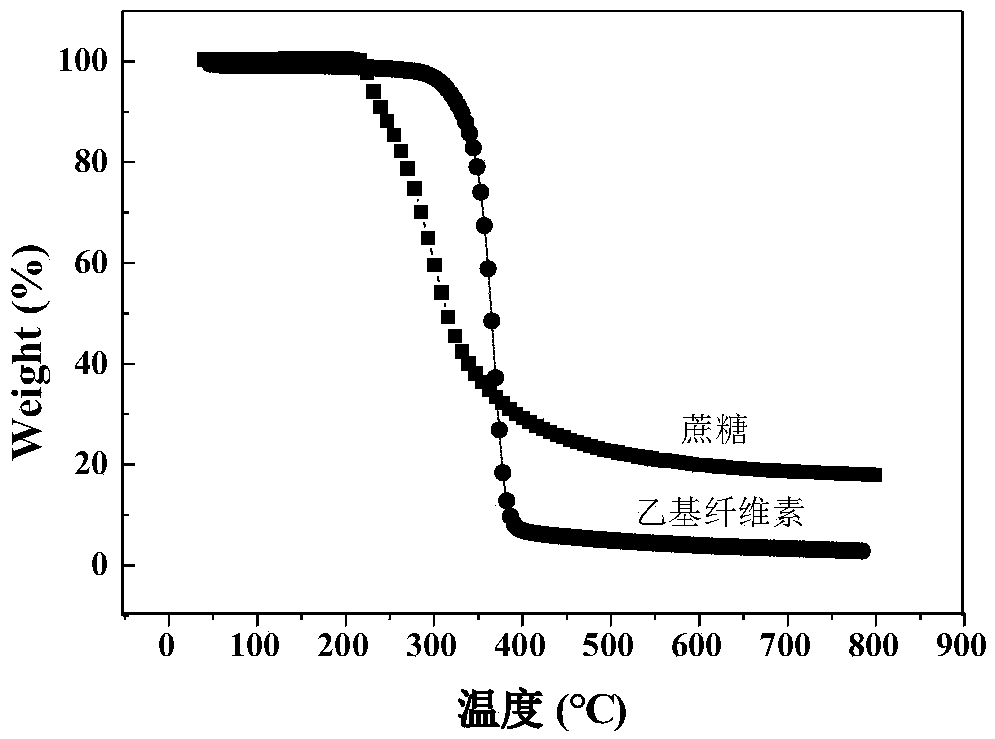

[0036] Weigh Ni respectively at a molar ratio of 1:1.05 0.5 co 0.2 m 0.3 (OH) 2 with Li 2 CO 3 , the single crystal larger ternary cathode material precursor Ni 0.5 co 0.2 m 0.3 (OH) 2 , sintered at 600°C for 6 hours in an oxygen atmosphere to obtain precursor oxides; the precursor oxides were dissociated into primary particles by a jet mill, the frequency of the classifier was 60Hz, and the air pressure was 10Mp; Dissociation products and Li 2 CO 3 Mix lithium for 0.5h, then sinter the mixture at 550°C for 6h in an oxygen atmosphere, crush it and sinter at 1050°C for 16h in an air atmosphere, cool, dissociate, and sieve to obtain a single crystal Li 1 Ni 0.5 co 0.2 mn 0.3 o 2 Positive electrode material matrix.

[0037] Ethyl cellulose and triethyl citrate were dissolved in ethanol at a ratio of 20:1 to prepare a 1% ethyl cellulose solution, and the single crystal Li 1 Ni 0.5 co 0.2 mn 0.3 o 2 The positive electrode material matrix was added to 5L of ethyl...

Embodiment 2

[0040] Weigh Ni respectively at a molar ratio of 1:1.02 0.6 co 0.2 m 0.2 (OH) 2 with LiOH·H 2 O, the single crystal larger ternary cathode material precursor Ni 0.6 co 0.2 m 0.2 (OH) 2 , sintered at 500°C for 4 hours in an oxygen atmosphere to obtain precursor oxides; the precursor oxides were dissociated into primary particles using a jet mill, the frequency of the classifier was 50Hz, and the air pressure was 12Mp; with LiOH·H 2 O mixed with lithium for 1.0h, the mixture was sintered at 450°C for 8h in an oxygen atmosphere, crushed and sintered for a second time at 1000°C in an oxygen atmosphere for 12h, cooled, dissociated, and sieved to obtain single crystal Li 1 Ni 0.8 co 0.1 mn 0.1 o 2 Positive electrode material matrix.

[0041] Dissolve hydroxyethyl cellulose and tributyl lemon in water at a mass ratio of 15:1 to prepare a 0.5% hydroxyethyl cellulose solution. single crystal Li 1 Ni 0.6 co 0.2 mn 0.2 o 2 The positive electrode material matrix was add...

Embodiment 3

[0044] Weigh Ni respectively at a molar ratio of 1:1.05 0.8 co 0.1 mn 0.1 (OH) 2 with LiOH·H 2 O, the single crystal larger ternary cathode material precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 , sintered at 500°C for 5 hours in an oxygen atmosphere to obtain precursor oxides; the precursor oxides were dissociated into primary particles using a jet mill, the frequency of the classifier was 50Hz, and the air pressure was 6Mp; with LiOH·H 2 O mixed with lithium for 1h, the mixture was sintered at 480°C for 6h in an oxygen atmosphere, crushed and then sintered at 900°C for 12h in an oxygen atmosphere, cooled, dissociated, and sieved to obtain single crystal Li 1 Ni 0.8 co 0.1 mn 0.1 o 2 Positive electrode material matrix.

[0045] Dissolve hydroxypropyl methylcellulose and dibutyl sebacate in water at a mass ratio of 30:1 to prepare a 2.5% hydroxypropyl methylcellulose solution. single crystal Li 1 Ni 0.8 co 0.1 mn 0.1 o 2 The positive electrode material matrix was ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com