Novel composite positive electrode, preparation method and use thereof and solid lithium battery

A composite cathode and solid electrolyte technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems that restrict the large-scale application of polymer electrolytes, low room temperature ionic conductivity, etc., and achieve great practical significance in production and wide production. Application, effect of reducing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

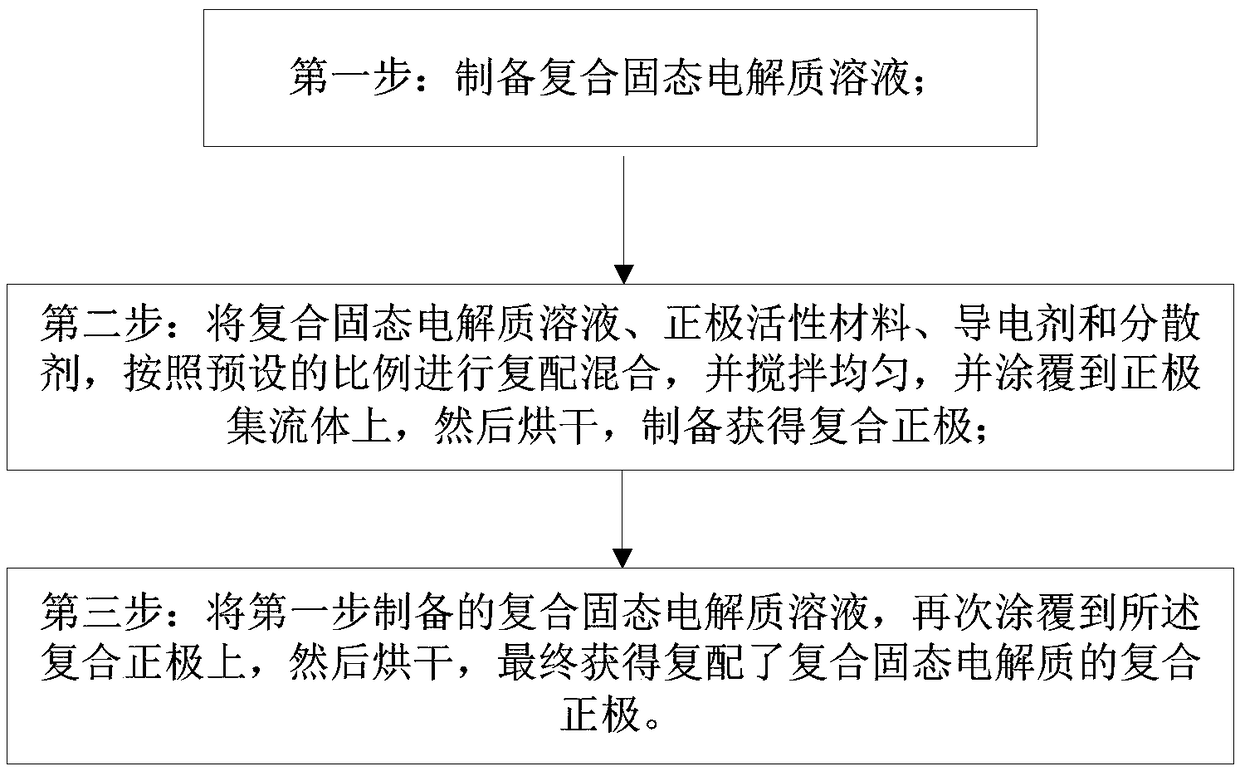

[0072] Also, see figure 1 As shown, the present invention also provides a method for preparing a novel composite positive electrode, which is used to prepare the above-mentioned novel composite positive electrode provided by the present invention, and can be used to specifically prepare a solid-state lithium battery. The method specifically includes the following steps:

[0073] The first step: preparing a composite solid electrolyte solution;

[0074] The second step: compound and mix the composite solid electrolyte solution, positive electrode active material, conductive agent and dispersant according to the preset ratio, and stir evenly, and apply it on the positive electrode current collector, and then dry it to prepare a composite positive electrode;

[0075] In the second step, the positive electrode current collector may be aluminum foil.

[0076] In the present invention, in the second step, the conductive agent comprises at least one of carbon black, krypton cyanoge...

specific Embodiment 1

[0098] In specific example 1, the present invention prepares the composite positive electrode based on novel composite solid state electrolyte, comprises the following steps:

[0099] The first step: first, get 5g of polymer PEO (400,000 molecular weight), and dissolve 5g of lithium salt LiTFSI in 90g of solvent tetrahydrofuran to prepare a polymer solid electrolyte solution. The weight percentage: polymer PEO is 5% , lithium salt LiTFSI is 5%; then, take 10g of tetraethyl orthosilicate and dissolve in 80g of formic acid, and mix 10g of ionic liquid, the ionic solution is specifically: 1-methyl-1-propylpyrrolidine bis (Trifluoromethanesulfonyl) imide salt is formulated into the first mixed solution consisting of ionic liquid, tetraethyl orthosilicate and formic acid, wherein the weight percentage is: tetraethyl orthosilicate is 10%, 1 -Methyl-1-propylpyrrolidine bis(trifluoromethanesulfonyl)imide salt is 10%, formic acid is 80%; then, the polymer solid electrolyte solution and...

specific Embodiment 2

[0106] In specific embodiment 2, the present invention prepares the composite positive electrode based on novel composite solid state electrolyte, comprises the following steps:

[0107] The first step, at first, get the polymer PEO (400,000 molecular weight) of 5g, the lithium salt LiTFSI of 5g are dissolved in the solvent tetrahydrofuran of 90g, be mixed with the polymer solid electrolyte solution, wherein weight percentage is: Polymer PEO is 5%, lithium salt LiTFSI is 5%; then, take 10g tetraethyl orthosilicate and dissolve in 80g formic acid, and mix 10g ionic liquid 1-methyl-1-propylpyrrolidine bis(trifluoromethanesulfonyl) Imine salt, formulated as a mixed solution consisting of ionic liquid, tetraethyl orthosilicate and formic acid, wherein the percentage by weight is: tetraethyl orthosilicate is 10%, ionic liquid 1-methyl-1-propane Pyrrolidine bis(trifluoromethanesulfonyl)imide salt is 10%; Finally, according to the required composite solid electrolyte formula, the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com